An explosive hollow picket

A hollow pile technology, applied in sheet pile walls, buildings, foundation structure engineering, etc., can solve the problems of unstable pile foundation, low bearing capacity, difficult pile drilling, etc., and achieve reasonable structure, simple structure, simple and feasible process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but not as any limitation to the present invention.

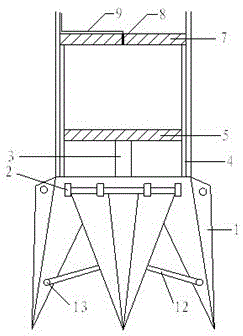

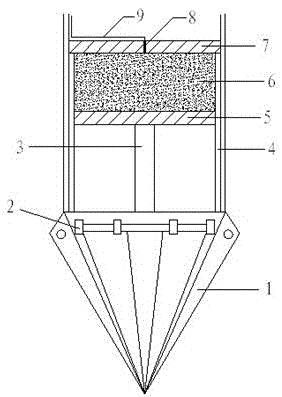

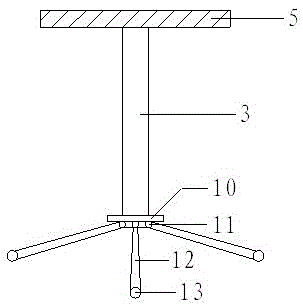

[0021] An explosive hollow picket such as figure 1 and figure 2 shown. Including the pile barrel 4; the bottom of the pile barrel 4 is hinged with a group of drill point valves through the hinge rod 2; each drill point valve 1 is evenly distributed along the bottom circumference of the pile barrel; each drill point valve 1 is provided with a hinge ball at the inner lower part 13; the hinge ball 13 is connected with the explosive propelling device arranged at the bottom of the stake barrel 4 . The pile barrel 4 is cylindrical, the inner diameter of the cylinder is 5-10 centimeters, and the thickness of the cylinder is 3-5 millimeters. The explosive propulsion device such as image 3 and Figure 4 shown. It includes a fixed plate 7 fixedly connected to the inner wall of the pile ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com