Unloading system used for automatically unloading circuit board

一种自动卸载、电路板的技术,应用在电气元件、电气元件、输送机等方向,能够解决作业员伤害、作业员受伤等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

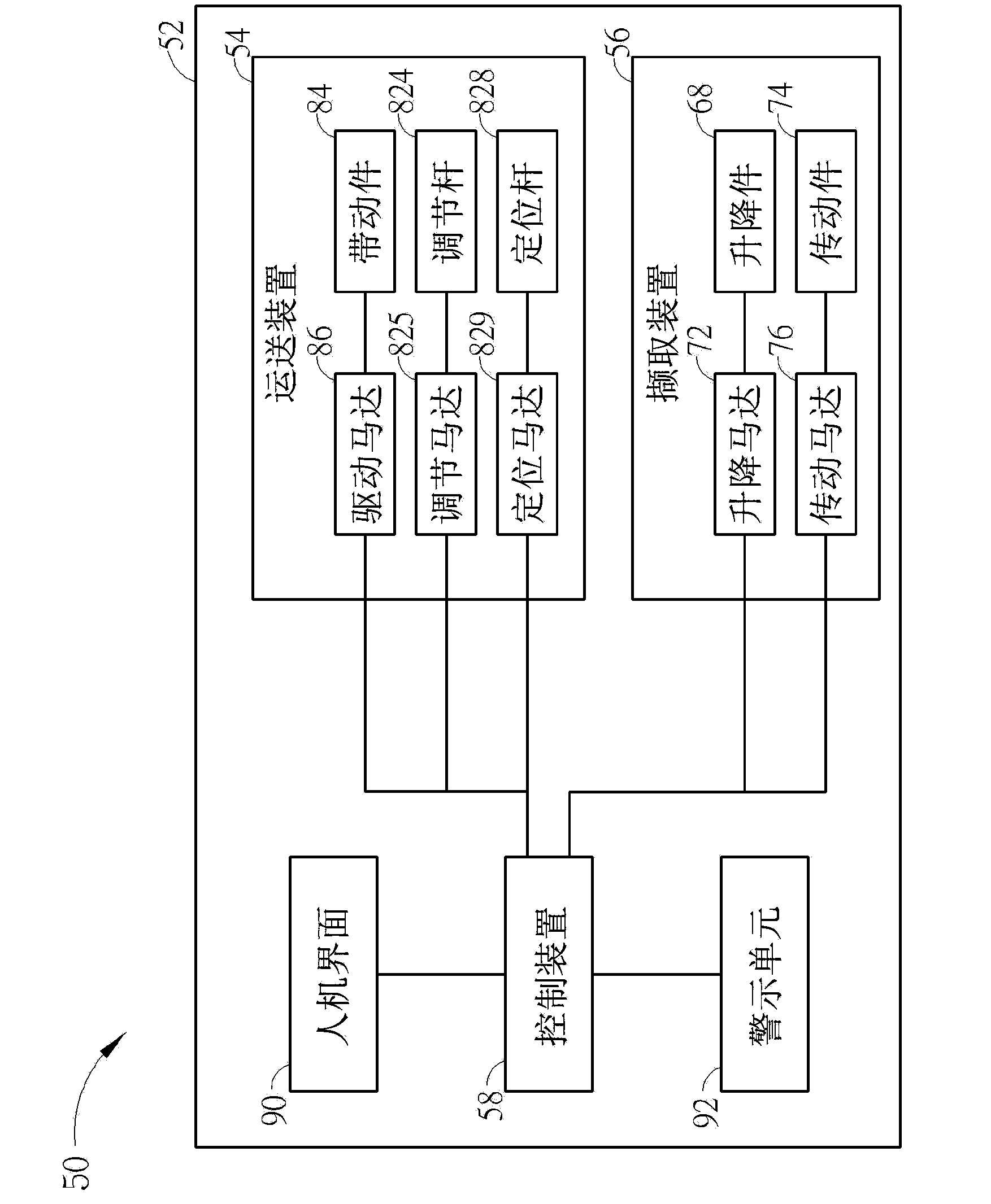

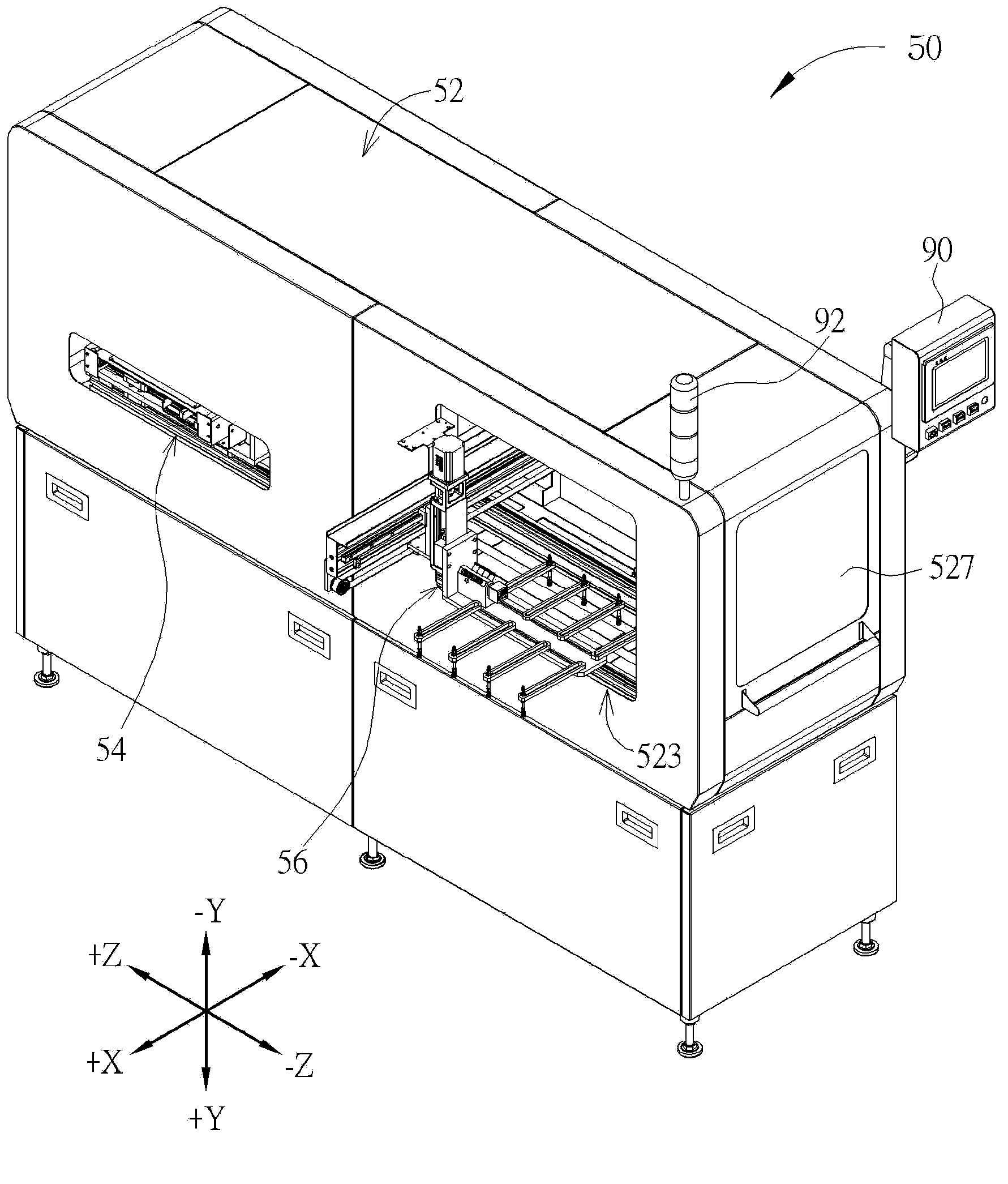

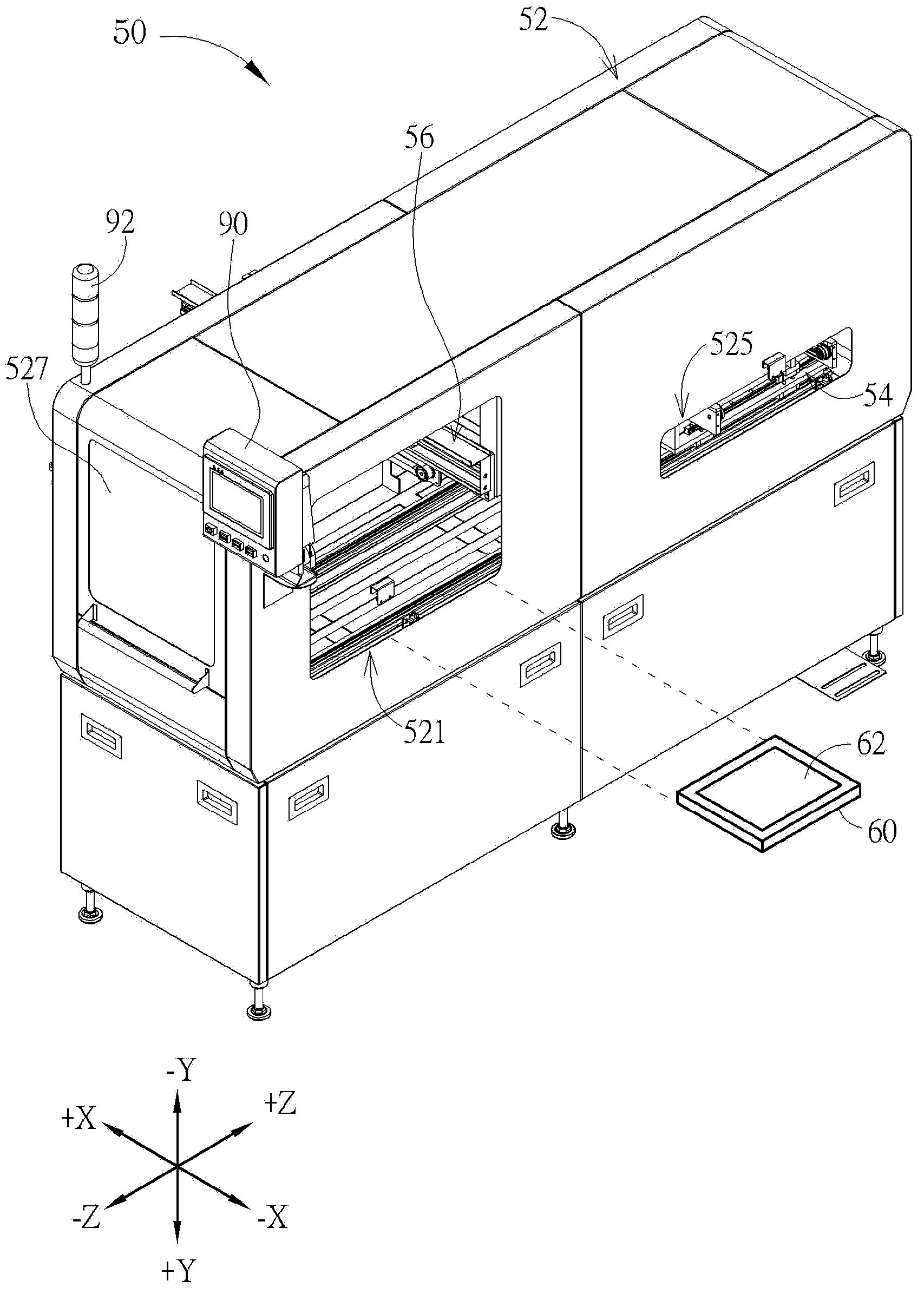

[0050] Please refer to Figure 1 to Figure 4 , figure 1 It is a functional block diagram of an unloading system 50 according to an embodiment of the present invention, figure 2 and image 3 It is a schematic diagram of the unloading system 50 in different viewing angles according to the embodiment of the present invention, Figure 4 It is a schematic diagram of the internal structure of the unloading system 50 according to the embodiment of the present invention. The unloading system 50 of the embodiment of the present invention includes a casing 52 , a transport device 54 , a retrieval device 56 and a control device 58 . The housing 52 is provided with a first inlet 521 , a first outlet 523 and a second outlet 525 . The conveying device 54 is installed in the housing 52, and the conveying device 54 is used to convey a carrier assembly 60 sent in from the first inlet 521 and a circuit board 62 arranged on the carrier assembly 60, wherein the carrier assembly 60 can be use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com