Automatic rubbish compression device of residential rubbish transfer station

A technology of garbage transfer station and pneumatic device, which is applied in the direction of garbage transmission, garbage collection, storage devices, etc., and can solve the problems of time-consuming, labor-intensive and uneconomical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

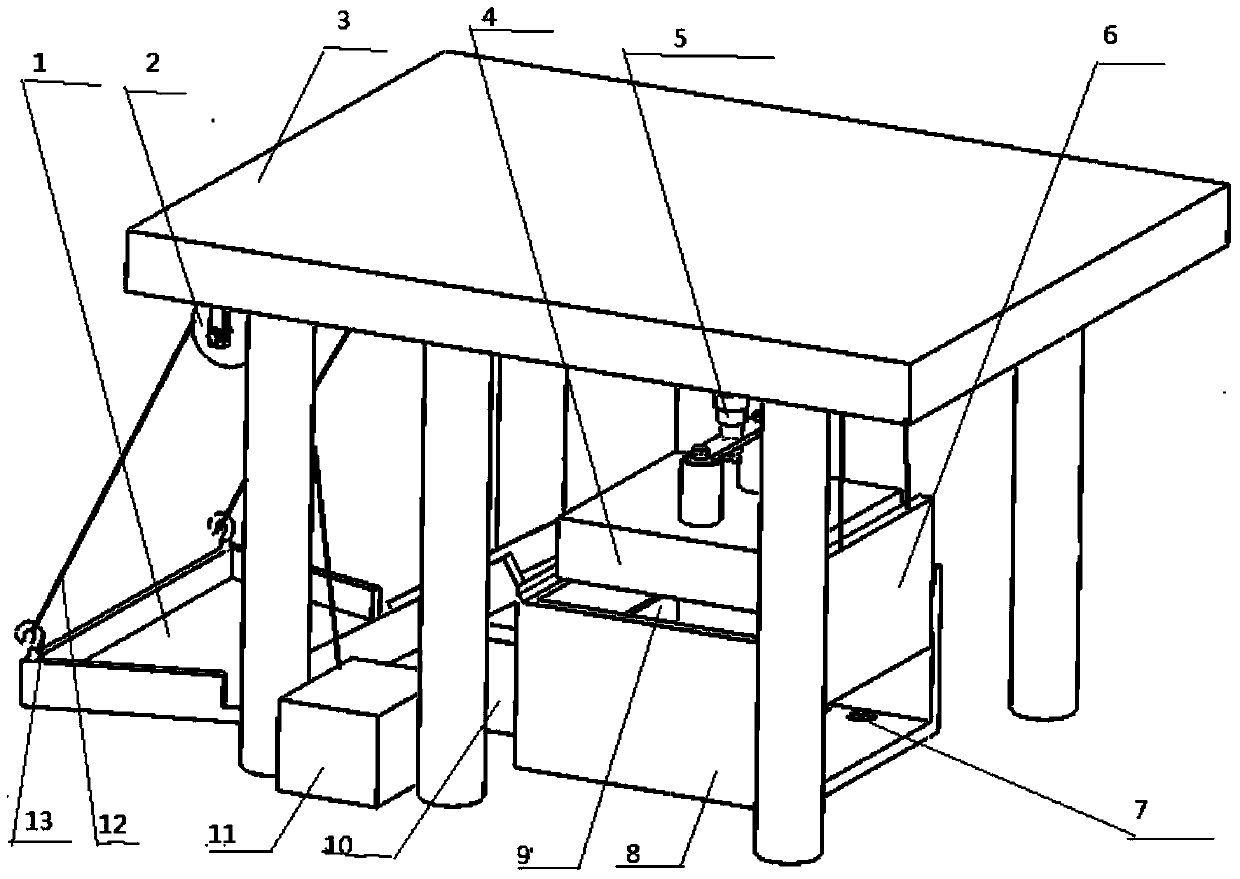

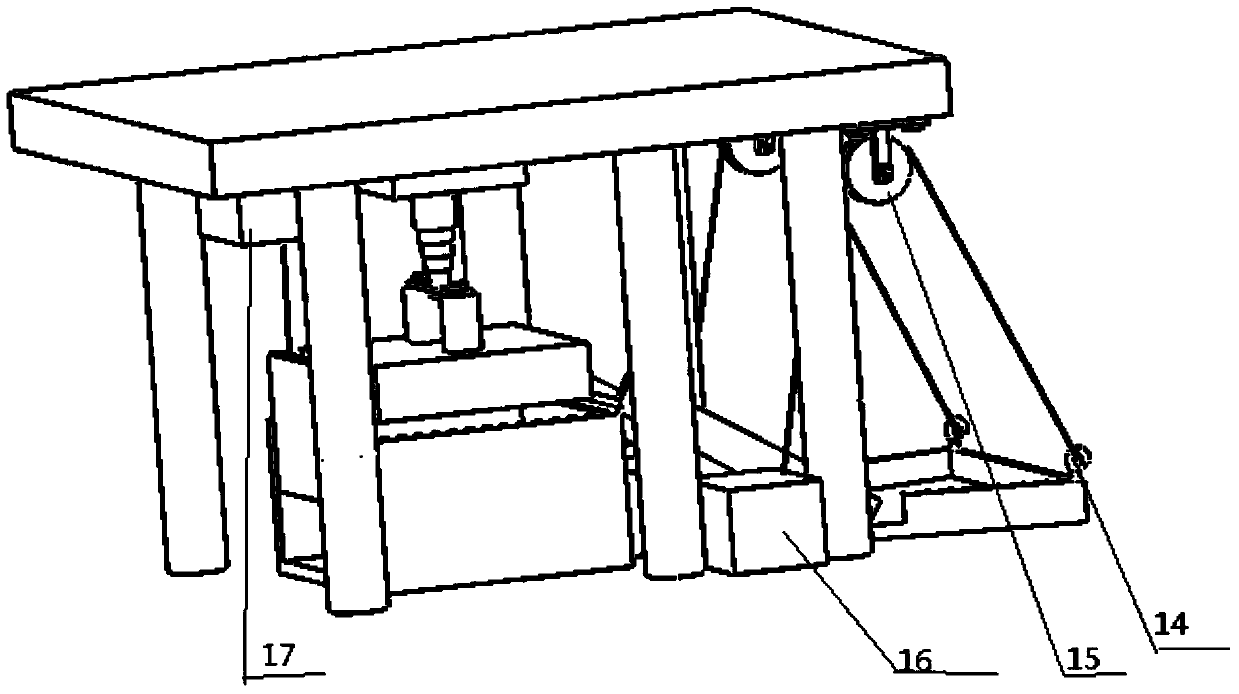

[0010] As shown in the figure, an automatic garbage compression device for a community garbage transfer station is composed of a feed hopper 1, a pulley 2, a basic support 3, a compression plate 4, a first pneumatic device 5, an outlet baffle 6, and a sewage outlet filter device 7. Garbage container 8, push plate 9, second pneumatic device 10, first motor 11, steel rope 12, hook one 13, hook two 14, pulley two 15, second motor 16, third motor 17 Yes, the base support 3 is installed on the ground, and the first hook 13 and the second hook 14 are installed on the feed hopper 1. The first hook 13 and the second hook 14 have steel ropes 12 bypassing the first pulley 2 and the second pulley 15 to connect On the first motor 11 and the second motor 16 shafts, the first motor 11 and the second motor 16 are installed on the ground, the pulley one 2 and the pulley two 15 are installed on the top of the base support 3, and the compression plate 4 is connected under the first pneumatic dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com