Wheel type electric soldering iron auxiliary soldering wire feeding device

An electric soldering iron and roller-type technology, applied in auxiliary devices, tin feeding devices, welding equipment, etc., can solve the problems of inability to adjust, complex structure, high price, etc., achieve convenient operation, high reliability, and improve welding accuracy and efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings, without limiting the scope of protection.

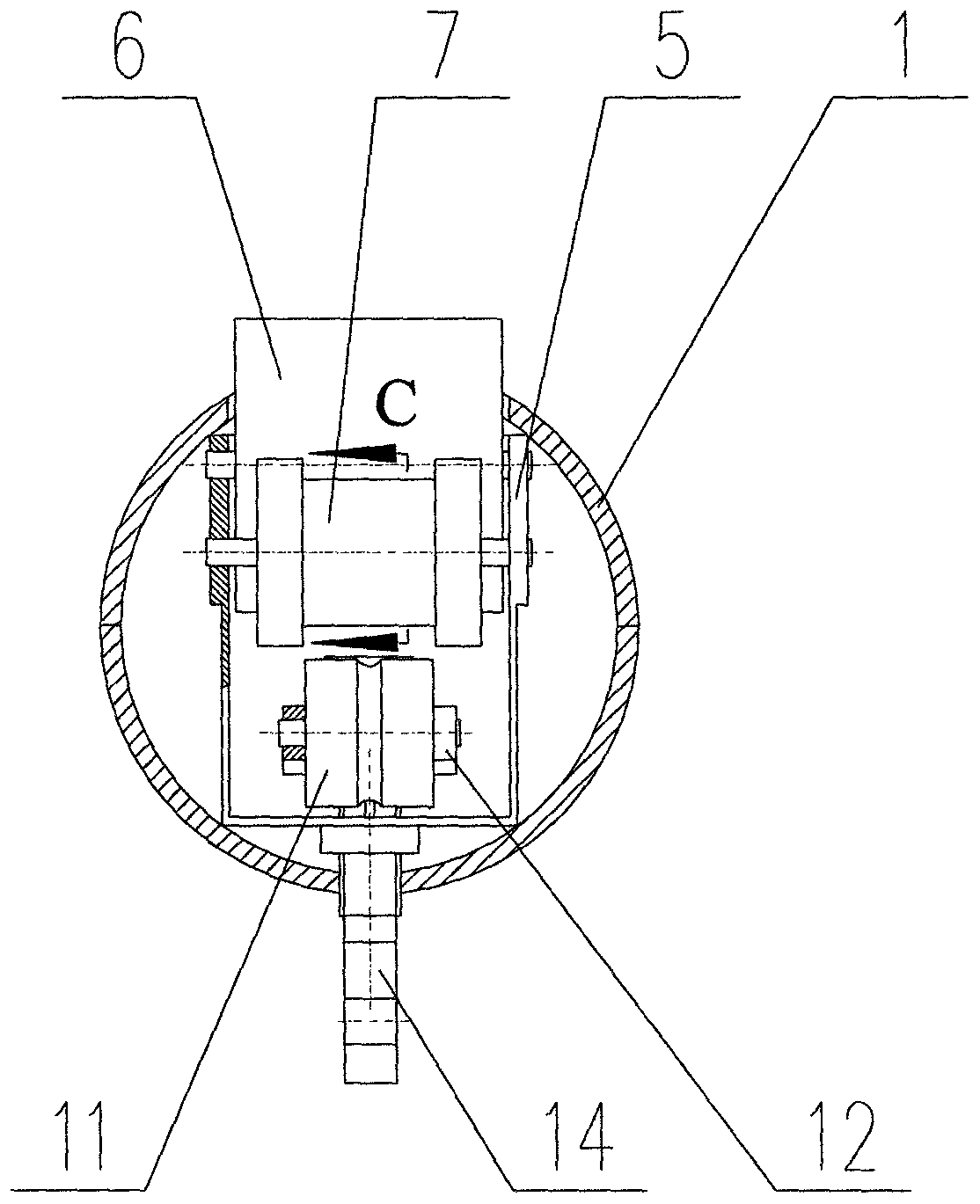

[0017] A roller type electric soldering iron welding auxiliary wire feeding device, its structure is as follows figure 1 with Figure 7 As shown, the inside of the device shell 1 is provided with a wire feeding wheel train fixing frame 5, a welding wire feeding catheter fixing frame 2 and a welding wire catheter fixing frame 10, and the outside is provided with a fixing clip 19 and a fixing clip rotating shaft joint 18; the welding wire wheel fixing frame 5 The upper inner part is respectively fixed with the main dial 6, the upper left roller 7 and the upper right roller 4, and the lower roller fixing frame guide rods 15 are arranged on both sides of the inner lower part. 15 is provided with welding wire guide platform 16, and lower roller fixed frame 12 both sides are respectively fixed with left side lower roller 11 and righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com