Wettable silicone hydrogel contact lenses

A hydrogel contact lens, contact lens technology, applied in glasses/goggles, instruments, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

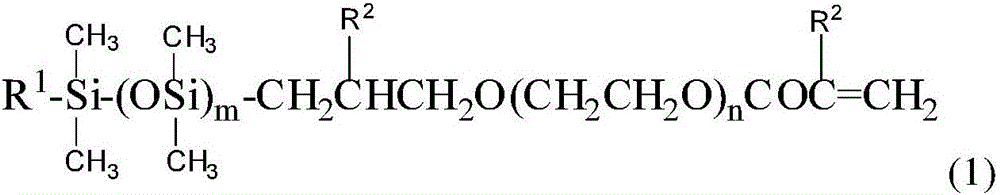

Image

Examples

example

[0224] The following Examples 1 to 25 illustrate certain aspects and advantages of the invention, which should not be construed as limiting thereby.

[0225] As can be readily determined by reading the examples below, all of the example formulations contained no organic diluents. Also, all example formulations are free of N,N-dimethylacrylamide (DMA). Additionally, all of the example formulations below are free of polymeric wetting agents. In addition, all example formulations included at least one hydrophilic amide monomer with one N-vinyl group. Most of the example formulations (Examples 4-5, 8-13, 15, and 17-25) included a second siloxane with a number average molecular weight greater than 7,000 Daltons.

[0226] The following chemicals are mentioned in Examples 1 to 25 and may be mentioned by their abbreviations.

[0227] Si1: 2-methyl-2-acrylic acid 2-[3-(9-butyl-1,1,3,3,5,5,7,7,9,9-decamethylpentasiloxane-1 -yl)propoxy]ethyl ester (CAS No. 1052075-57-6). (Si1 was ob...

example 1

[0271] Polymerizable compositions were obtained by mixing and filtering the following compounds in the indicated amounts using the procedures described in the Silicone Hydrogel Contact Lens Manufacturing and Testing Procedures given above.

[0272] compound (abbreviation)

unit quantity

Si1

30

Si3

3

VMA

45

EGMA

7

MMA

15

TEGDMA

0.8

AE

0.5

V-64

0.3

UV1

0.9

[0273] According to the manufacturing procedures and testing methods described in Silicone Hydrogel Contact Lens Manufacturing and Testing Procedures using a dry release process, a dry delensing process and the use of extracts containing volatile organic solvents and non-volatile Washing Process of Washing Fluids of Hydration Fluids of Liquid Compositions of Organic Solvents A batch of silicone hydrogel contact lenses was prepared and tested using this formulation. These contact lenses contain units derived from the two ...

example 2

[0276] Polymerizable compositions were obtained by mixing and filtering the following compounds in the indicated amounts using the procedures described in the Silicone Hydrogel Contact Lens Manufacturing and Testing Procedures given above.

[0277] compound (abbreviation)

unit quantity

Si1

30

Si3

3

VMA

45

EGMA

7

MMA

15

EGDMA

0.5

TEGDVE

0.1

AE

0.8

V-64

0.3

UV2

0.9

RBT1

0.01

TPP

0.5

[0278] According to the manufacturing procedures and testing methods described in Silicone Hydrogel Contact Lens Manufacturing and Testing Procedures using a dry release process, a dry delensing process and the use of extracts containing volatile organic solvents and non-volatile Washing Process of Washing Fluids of Hydration Fluids of Liquid Compositions of Organic Solvents A batch of silicone hydrogel contact lenses was prepared and tested using this formulation....

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com