Rotor for laboratory centrifuge

A technology of laboratory centrifuges and rotors, which is applied in centrifuges and other directions, and can solve complex and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

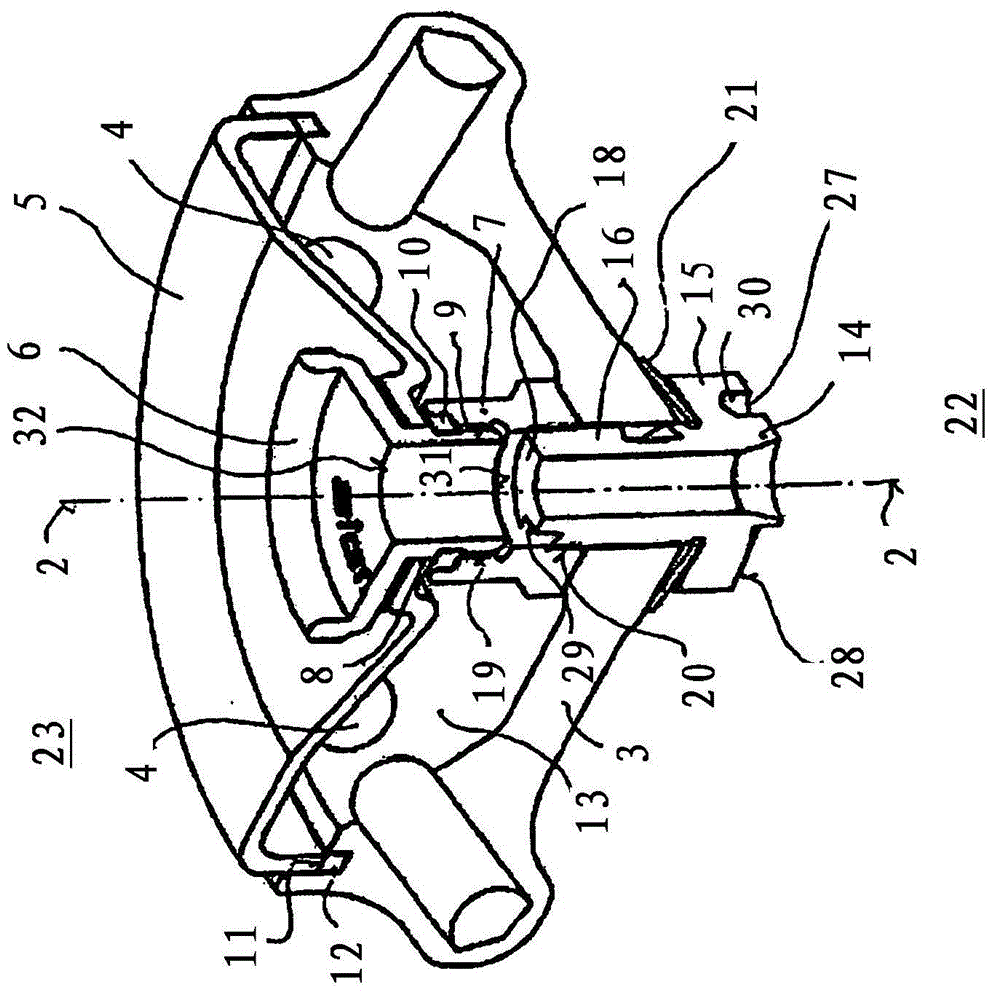

[0017] exist figure 1 and 2 In , the rotor of a laboratory centrifuge, not otherwise indicated with reference numerals, is designated with reference numeral 1 , which rotor has a rotationally symmetrical structure about its axis 2 . The rotor comprises a rotor body 3, in the peripheral region of which is provided a receptacle 4, in a manner known per se, for receiving a container in which there is Processed material mixtures.

[0018] A cover is identified with reference numeral 5 , which covers the rotor body 3 and is screwed via a cover screw 6 extending coaxially to the axis 2 with a nut 7 which is located below the cover 5 . Attached to the cover screw 6 is a hollow cylindrical part 9 with an external thread that extends through the recess 8 of the cover 5 and engages with the internal thread 19 of the nut 7 . A sealing ring 10 , preferably in the form of a four-lip seal, is accommodated between cover 5 and nut 7 , to be precise in annular spaces diametrically opposite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com