Spin drying mechanism

A technology for drying motors and materials, which is applied in the direction of drying/impregnation machines, etc., which can solve the problems of manual feeding, long drying and dehydration time, and unsatisfactory drying and dehydration effects, so as to improve production efficiency, good effect, and structure Reasonable and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

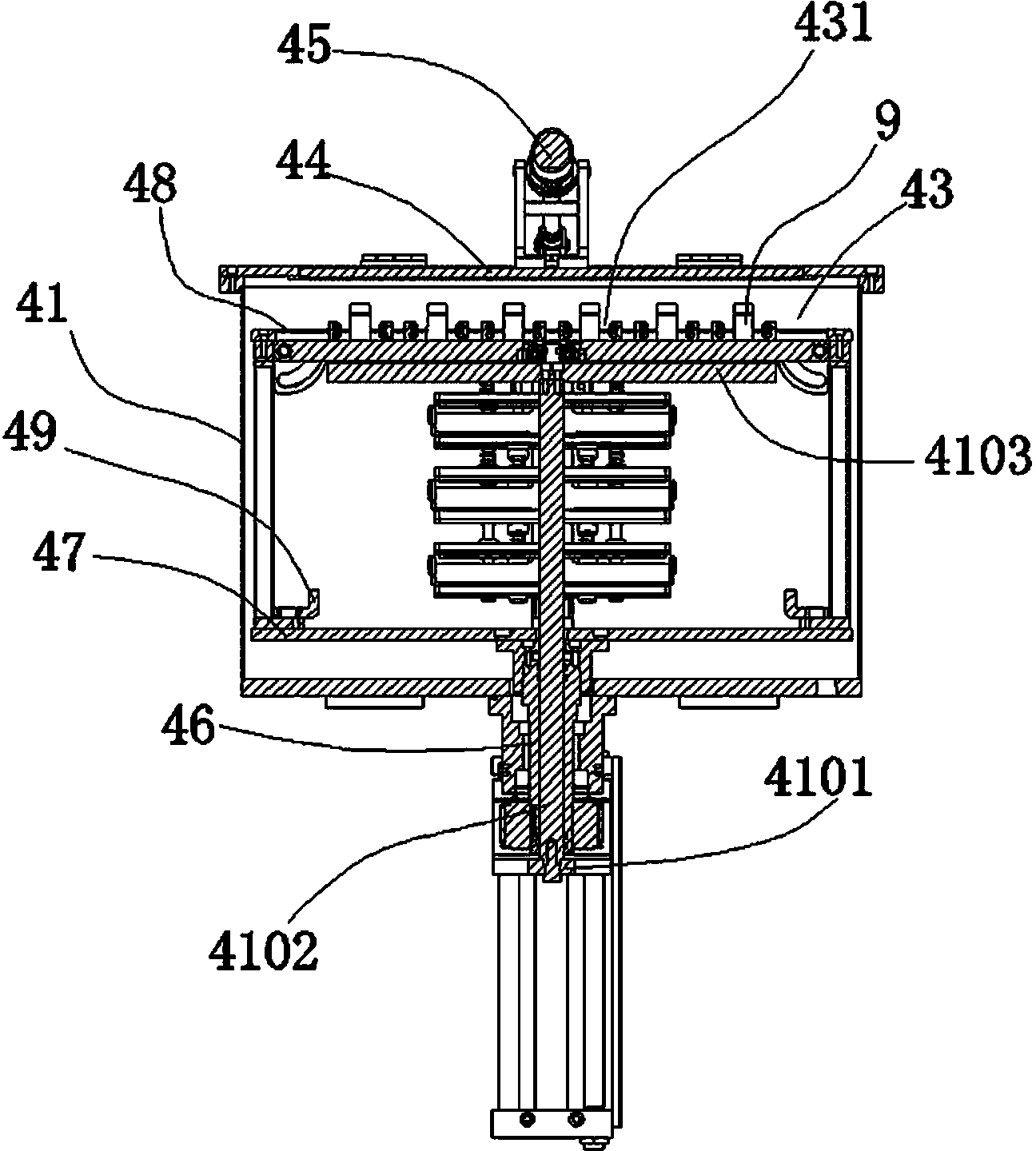

[0022] Example: see Figure 1 to Figure 3 , a kind of spin-drying mechanism of the present invention, it comprises spin-drying outer barrel 41, is provided with in this spin-dry outer barrel 41 the rotatable spin-drying support driven by spin-drying motor 42 and several spin-drying brackets that are evenly arranged by the circumferential direction. The drying basket 43 is provided with some third material holding tanks 431 on the drying basket 43, the width of the third material holding tanks 431 is adapted to the material to be impregnated, and in this embodiment the material to be impregnated is a capacitor The electric core, in other embodiments, can also be transformer coils and other components that need to be impregnated. One end of the drying basket 43 is hinged on the drying support, and the bottom of the drying outer barrel 41 is also provided with a material carrying material. It is used to jack up the other end of the drying basket 43 and make the drying basket 43 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com