amoled pixel test circuit

A technology for testing circuits and pixels, applied in static indicators, instruments, etc., can solve problems such as increasing the cost of supporting equipment, and achieve the effect of reducing the number of independent probes and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

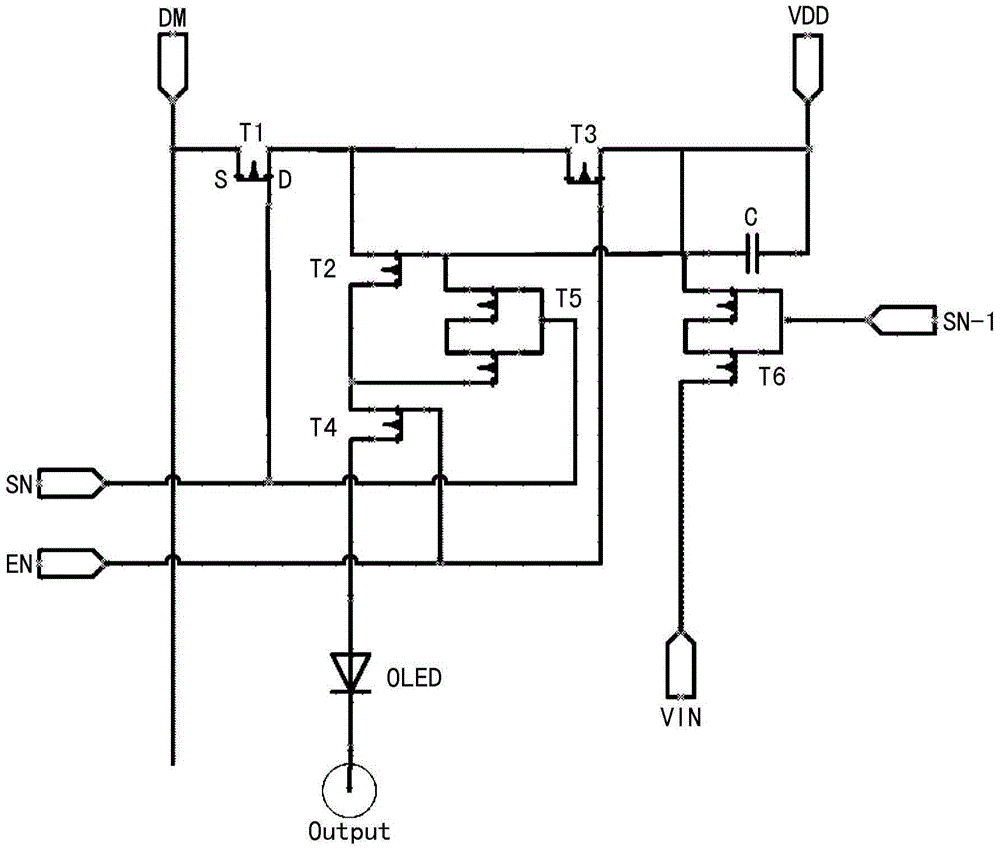

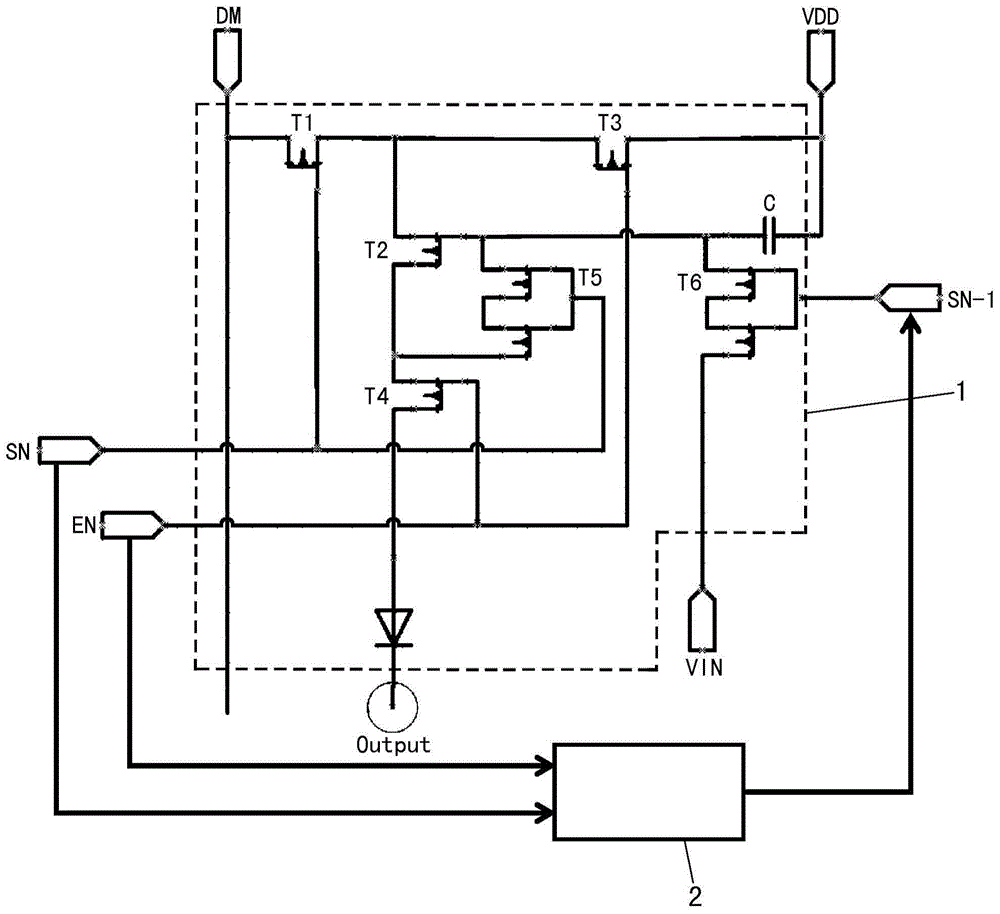

[0023] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

[0024] In the following drawings, the same reference numerals are attached to the same or corresponding parts, and repeated descriptions will be omitted.

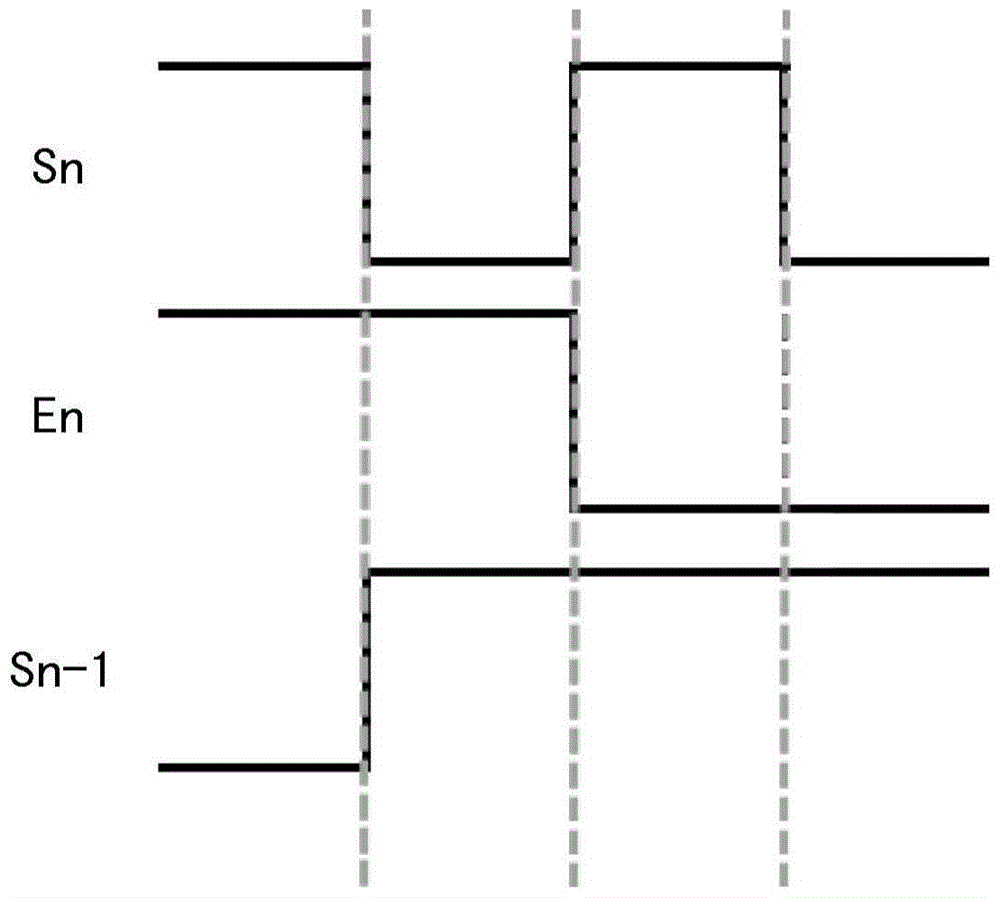

[0025] figure 2 yes means figure 1 The timing waveform diagram of the lighting control signal, the current scan signal and the front row scan signal of the pixel test circuit shown.

[0026] Such as figure 2 As shown, when the current scanning signal SN and the light-emitting control signal EN are both high level 1, the front row scanning signal SN-1 is low-level 0; when the current scanning signal SN is low-level 0, the light-emitting control signal EN is When the high level is 1, the front row scanning signal SN-1 is high level 1; when the current scanning signal SN is high level 1 and the light control signal EN is low level 0, the front row scanning signal SN-1 is high Level 1; when the current sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com