Method for testing contact thermal resistance among thin-layer materials based on 3-omega method

A thin-layer material and test method technology, applied in the direction of thermal development of materials, can solve the problems of difficult to guarantee measurement accuracy, complex formula derivation, and many factors of measurement results, achieve fast measurement, avoid complex formula derivation and calculation, geometric low size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

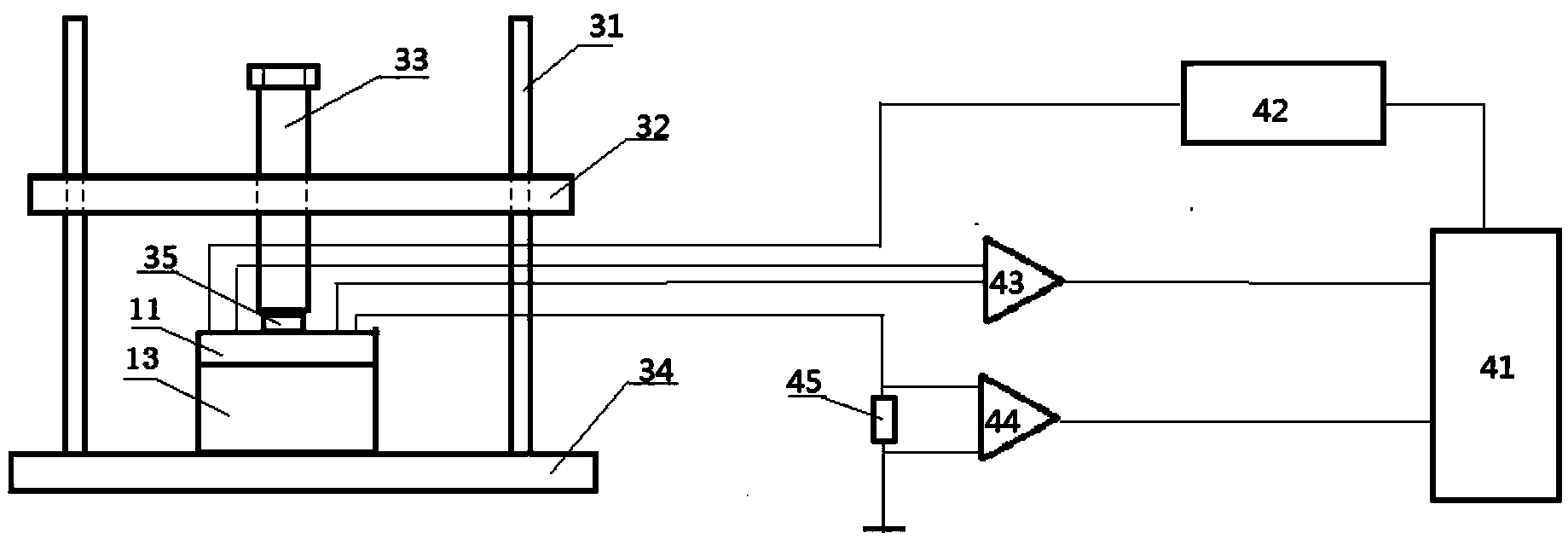

[0024] combine Figure 1 to Figure 6 :

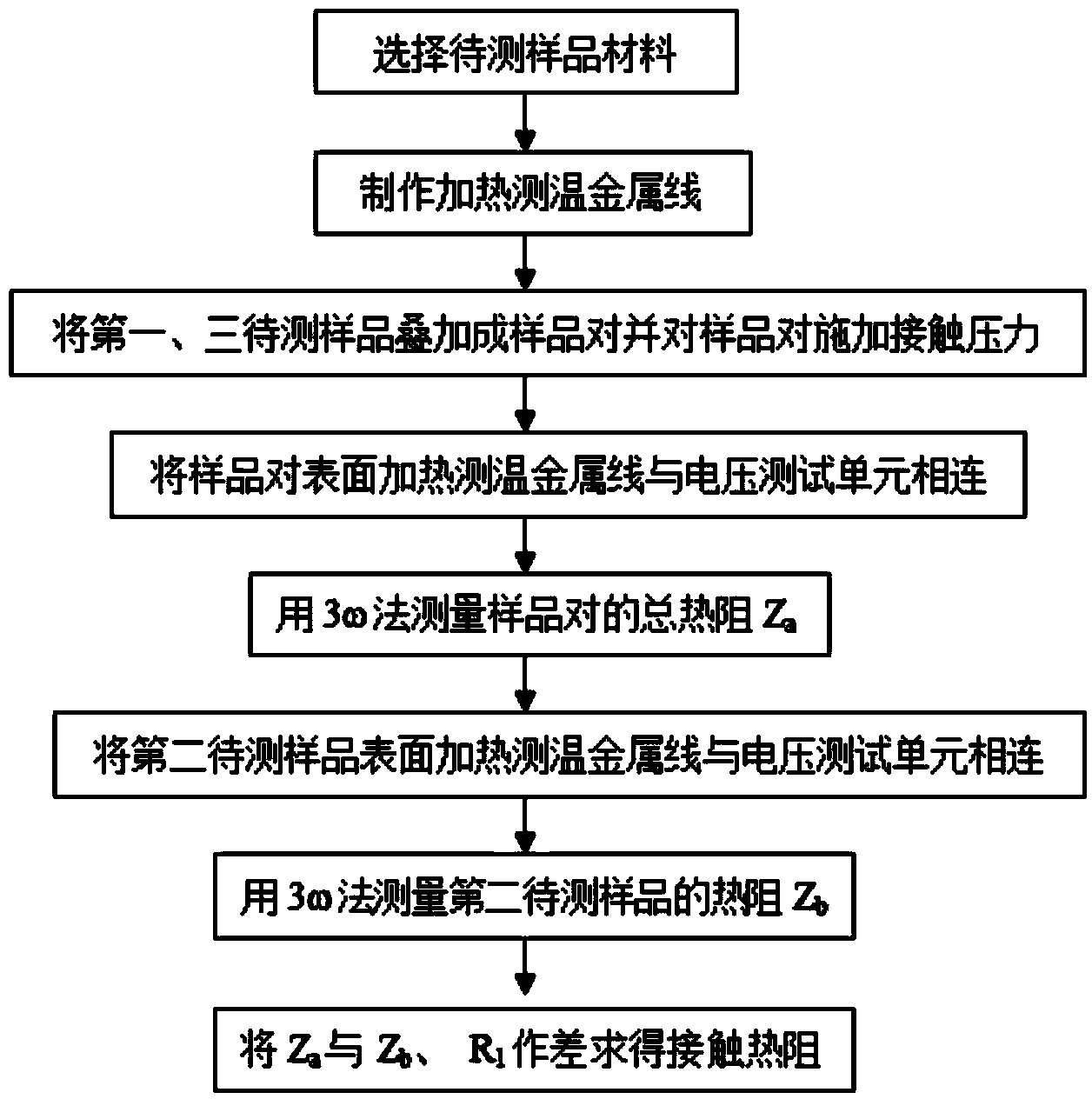

[0025] A test method for contact thermal resistance between thin-layer materials based on the 3ω method, the test steps for realizing the method are as follows:

[0026] Step 1: Select the materials of the first sample to be tested 11 and the second sample to be tested 12, and select a third sample to be tested 13 that is the same material as the second sample to be tested 12;

[0027] Step 2: Make a heating and temperature measuring metal wire 21 on one side of the first sample to be tested 11, and make a heating and temperature measuring metal wire 22 on one side of the second sample to be tested. If the first sample to be tested 11 or The second sample to be tested 12 is a metal material, then first deposits a layer of insulating film on the surface of the heating and temperature measuring metal wire;

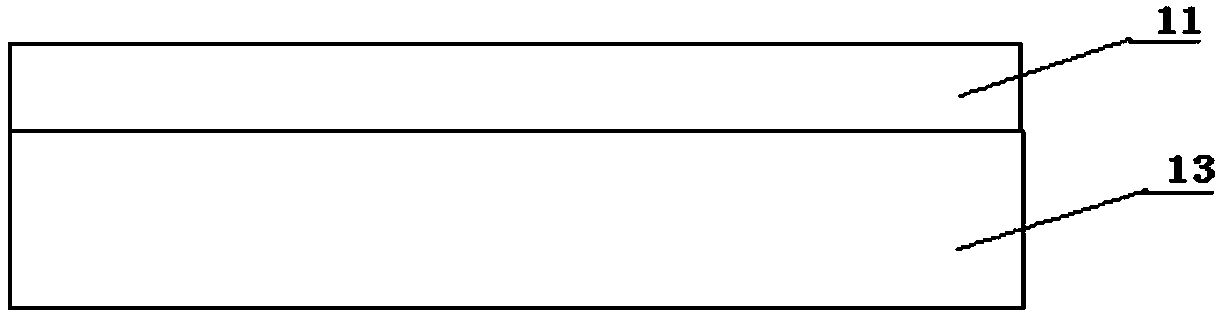

[0028] Step 3: Place the first sample to be tested 11 with its heating and temperature measuring metal wire 21 facing up on the th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com