X-ray source for X-ray raster differential phase-contrast imaging

A differential phase contrast and X-ray technology, applied in the field of X-ray imaging, can solve the problems of difficult absorption grating manufacturing process, high cost, limited field of view, etc., to overcome image quality degradation, large emission current, and wide radiation field of view Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

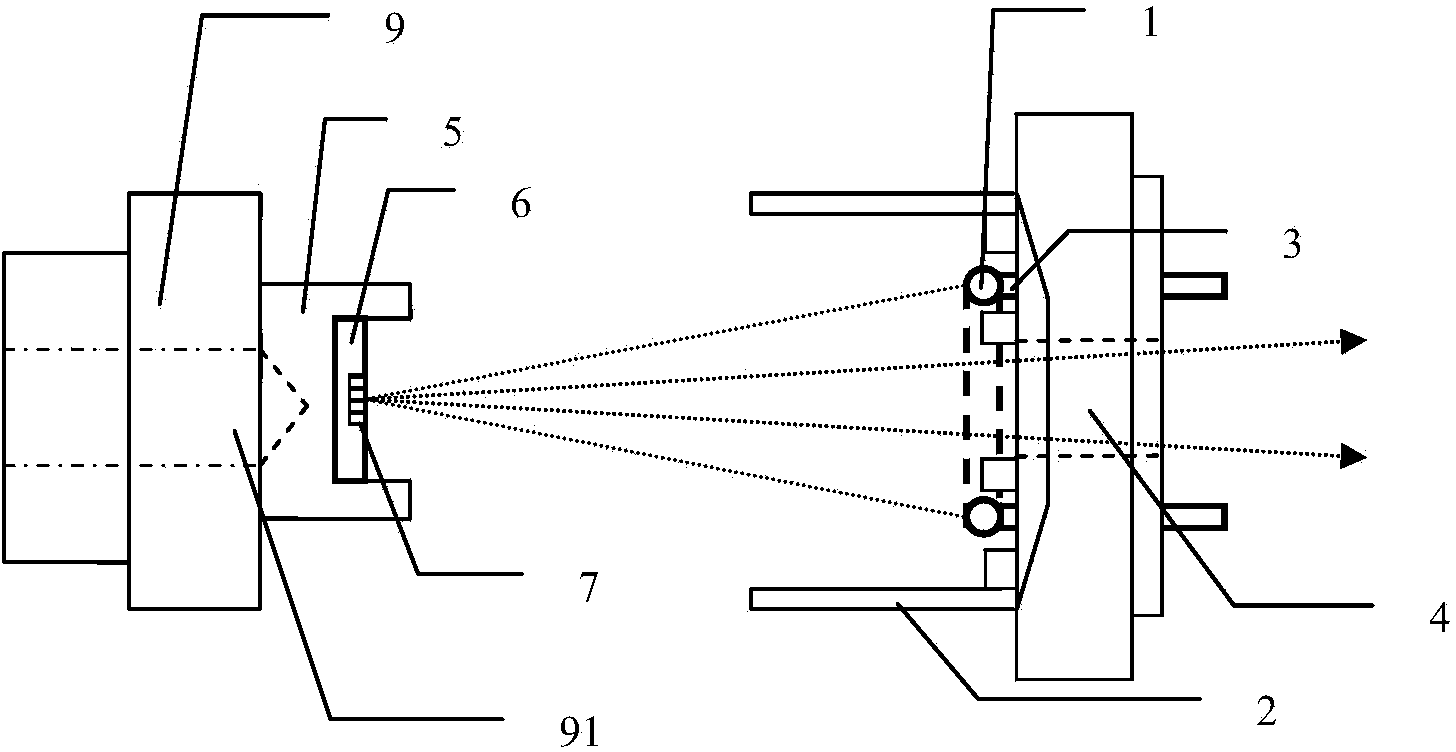

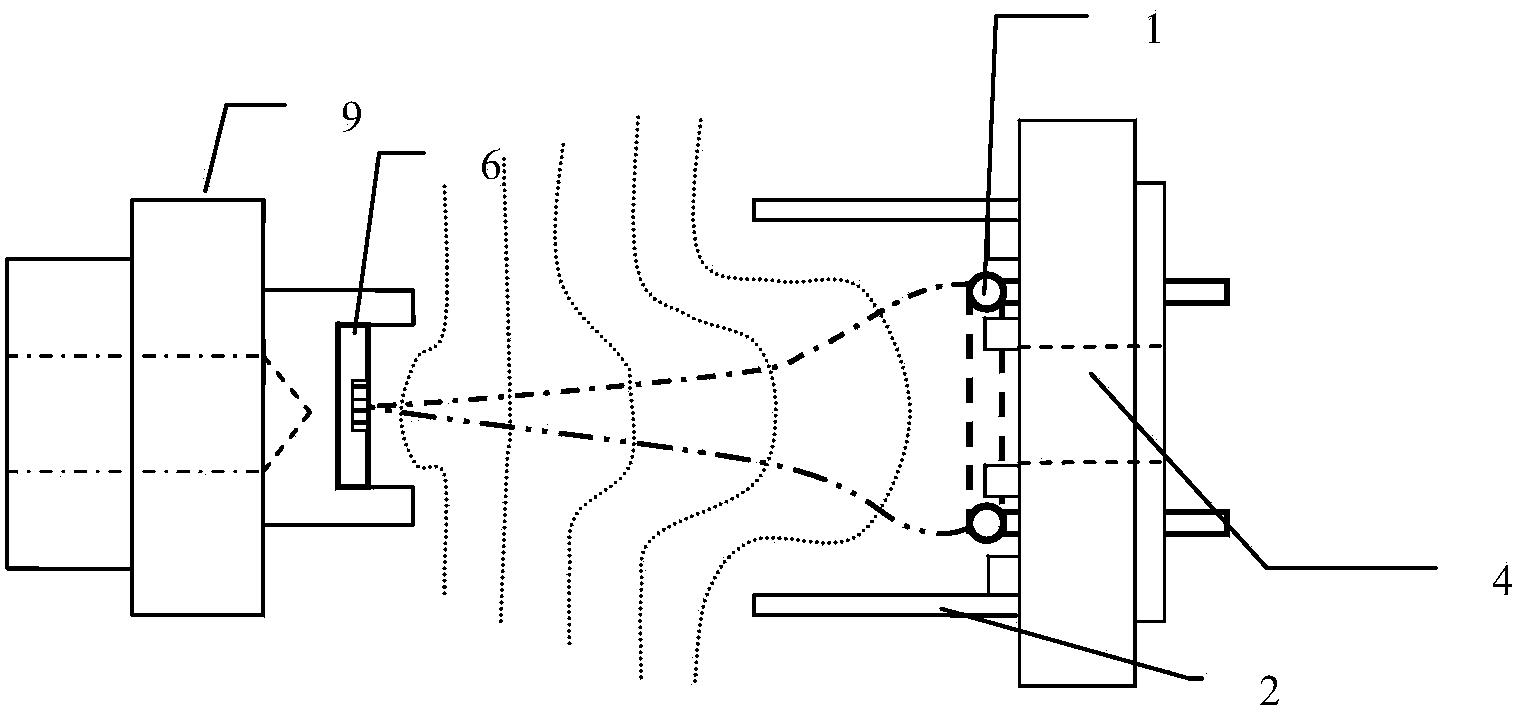

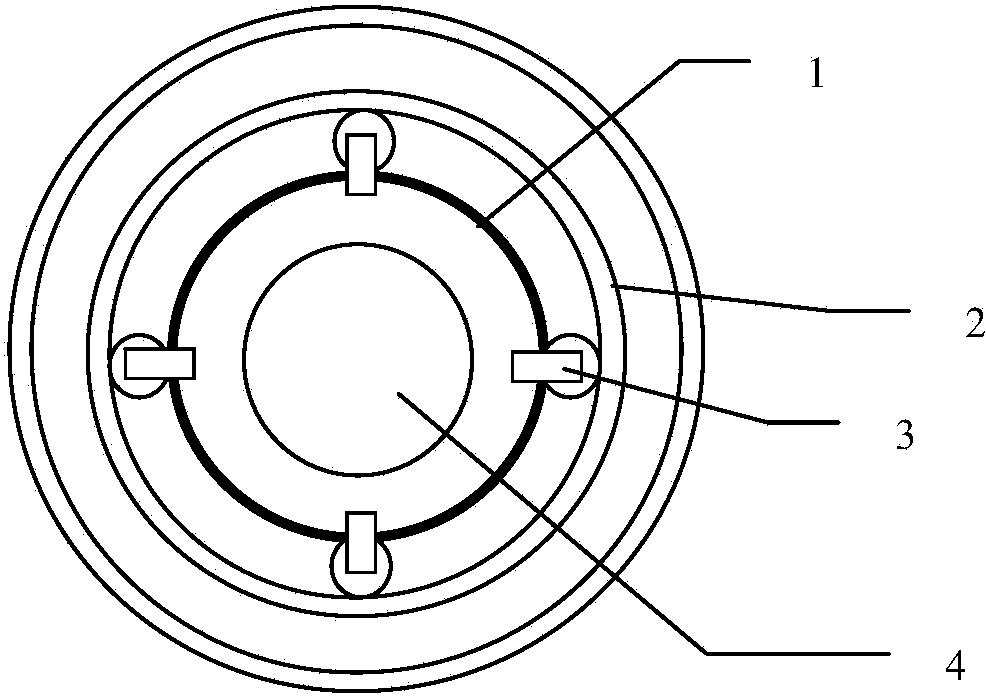

[0040] Such as Figure 1-6 As shown, an X-ray source for X-ray grating differential phase contrast imaging includes an annular cathode 1 for emitting electron beams, an anode target 6 for emitting X-rays in response to the incident electron beams, and an anode target 6 for accelerating and converging The electrode structure of the electron beam, the cathode heating power supply (not shown) for heating the annular cathode 1; the annular cathode 1 is arranged opposite to the target surface of the anode target 6, and the corresponding annular cathode 1 is arranged behind the annular cathode 1 The X-ray exit window 4 in the middle position and parallel to the target surface of the anode target 6; the target surface of the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Circle radius | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com