Fatigue cracking simulation testing method and apparatus for seamless expansion joint material of bridge

A technology of seamless expansion and fatigue cracking, applied in the direction of applying repeated force/pulsation force to test the strength of materials, to achieve the effect of accurate real service performance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

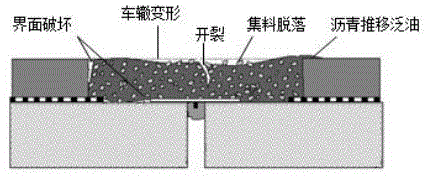

Problems solved by technology

Method used

Image

Examples

Embodiment 1

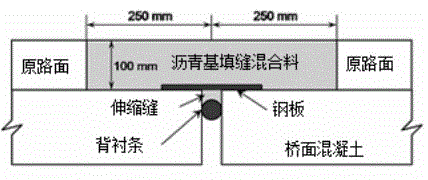

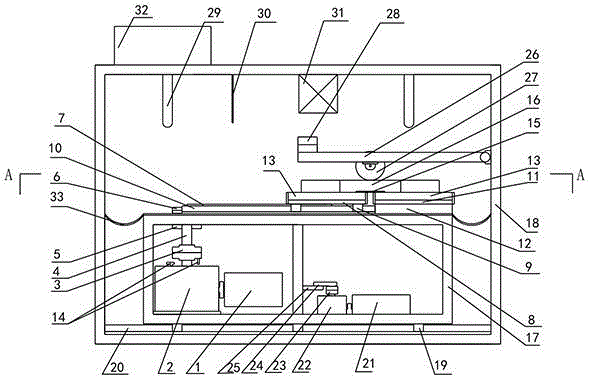

[0066] Place the concrete member 13 on the first steel plate 8 of the test platform, fix it on the second steel plate 11, lay the third steel plate (thin-layer steel plate) 15 directly above the joint (ie bridge seamless expansion joint) 35, and place the The bridge seamless expansion joint material (modified asphalt binder: aggregate mass ratio = 1:5) 16 is paved in 2 concrete members 13 to make a test piece (length 500mm×width 400mm×thickness 100mm). After curing for 24 hours, place the solid rubber tire 27 on the surface of the test piece 16, adjust the counterweight 28 so that the wheel pressure is 0.7MPa, the relative travel distance between the tire 27 and the test piece 16 is 50cm, and the traveling speed is 2.0km / h . The rotation radius of the first crank 6 is adjusted, the horizontal stretching distance of the test piece 16 is 10 mm, and the relative reciprocating motion speed between the first steel plate 8 and the second steel plate 11 is 50 mm / min. Open the contro...

Embodiment 2

[0068] Place the concrete member 13 on the first steel plate 8 of the test platform, fix it on the second steel plate 11, lay the third steel plate (thin-layer steel plate) 15 directly above the joint (ie bridge seamless expansion joint) 35, and place the The bridge seamless expansion joint material (modified asphalt binder: aggregate mass ratio = 1:3) 16 is paved in 2 concrete members 13 to make a specimen (length 700mm×width 400mm×thickness 100mm). After curing for 24 hours, place the solid rubber tire 27 on the surface of the test piece 16, adjust the counterweight 28 so that the wheel pressure is 2.0MPa, the relative travel distance between the tire 27 and the test piece 16 is 70cm, and the traveling speed is 3.0km / h . The rotation radius of the first crank 6 is adjusted, the horizontal stretching distance of the test piece 16 is 70 mm, and the relative reciprocating motion speed between the first steel plate 8 and the second steel plate 11 is 100 mm / min. Turn on the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com