A superheated steam drying system and process

A technology of superheated steam and drying process, which is applied in the directions of heating to dry solid materials, drying solid materials, and drying gas arrangement, etc. It can solve the problems of rarely used production and high technical threshold, and achieve fast drying speed and large heat transfer coefficient , Remarkable energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings.

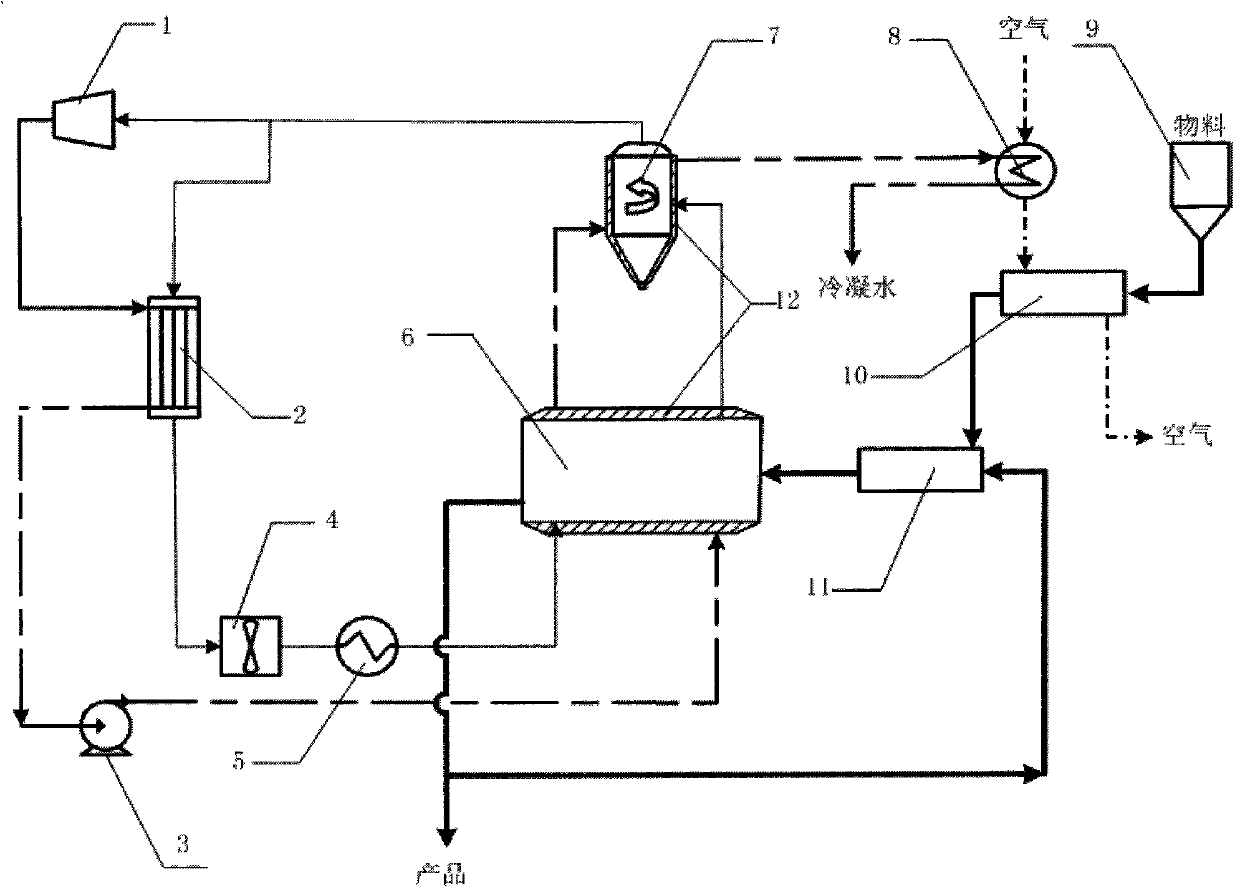

[0012] figure 1 Show the superheated steam drying system process flow chart of the present invention, refer to figure 1 As shown, the system workflow is as follows:

[0013] 1) Send the material to be dried into the drying chamber through a belt drive or other transmission mechanism, and then start the system. During the system start-up process, no more materials to be dried will be added. After the system is started, the feeding system will work again and the materials to be dried will be continuously fed into the system;

[0014] 2) When the system is started, the heater (5) heats the air, and the hot air is driven by the circulation fan (4), at this time the hot air becomes a closed cycle in the system. During the drying process, the moisture in the material quickly evaporates into the hot air, and most of the air in the system is replaced by steam. At ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com