Fuel injection valve

A fuel injection valve and needle valve technology is applied to direct injection in gasoline cylinders. It can solve the problems of incomplete closing of the injector, affecting the precise injection of the injector, etc., and achieve the effect of increasing the electromagnetic force, improving the ability, and improving the ability of multiple injections.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

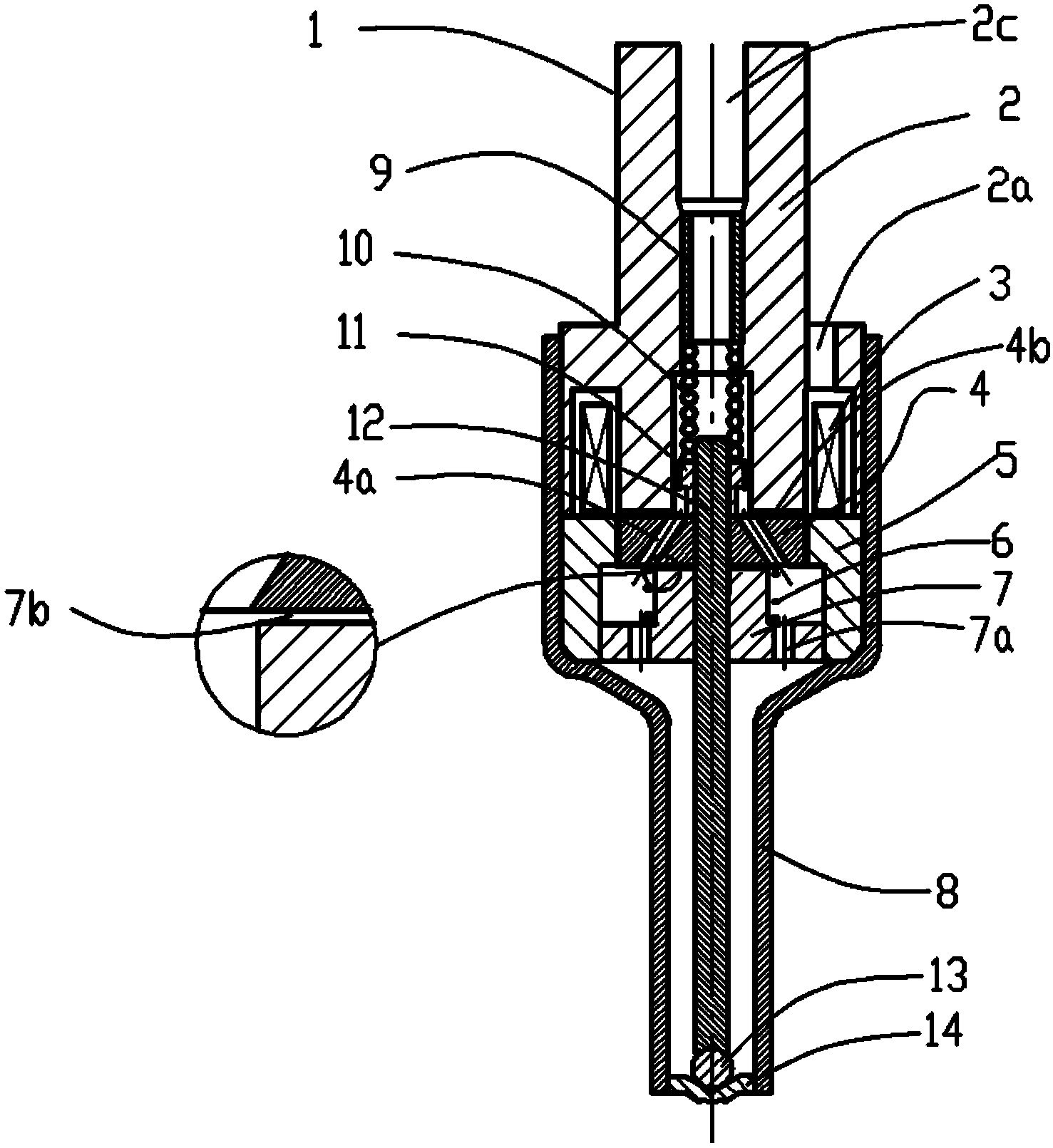

[0025] A fuel injection valve 1 ( figure 1 ):

[0026] Including magnetic core 2, coil 3, armature 4, magnetic ring 5, damping spring 6, damping block 7, outer shell 8, limit core 9, control spring 10, spring seat 11, needle valve 12, sealing ball 13, sealing ball Seat 14.

[0027] Its assembly method:

[0028] 1), press the coil 3 assembly (the coil skeleton needs to be fixed) into the coil slot 2b ( figure 2 ), the coil leads are drawn out from hole 2a;

[0029] 2), the coil groove 2b and the coil hole 2a are injected to fix the coil;

[0030] 3) Fix the limit core 9 in the inner cavity of the magnetic core 2 by means of interference;

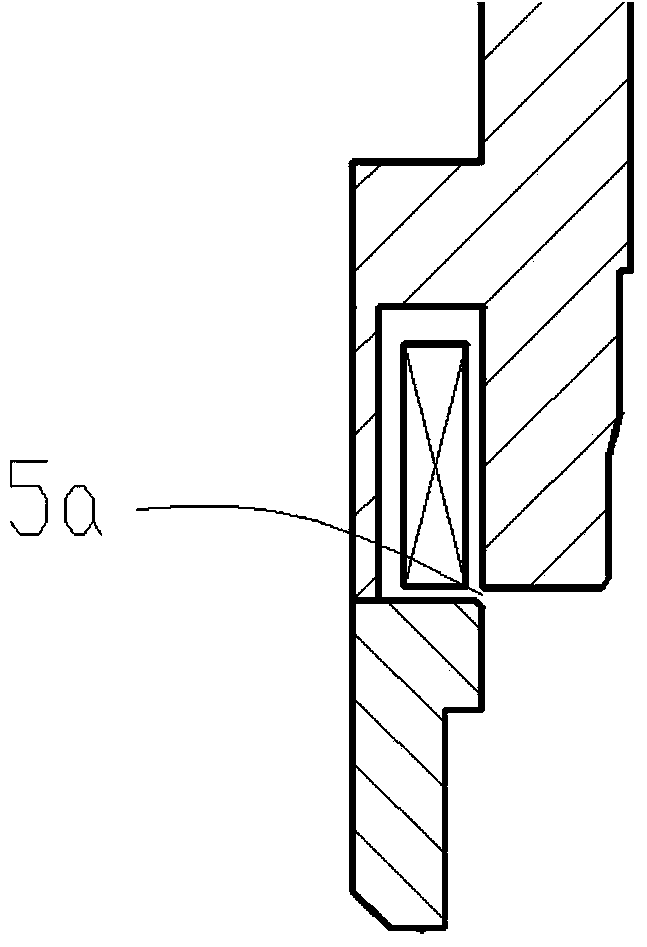

[0031] 4) Connect the magnetic ring 5 and the magnetic core 2 together by welding at the outer circular joint (concentricity must be ensured);

[0032] 5), the needle valve 12 is welded together with the spring seat 11, and the armature 4 is set on the needle valve;

[0033] 6) Push the armature 4 up until it touches the lower end su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com