Wind power tower with long and short legs

A technology of long and short legs and towers, applied in the direction of towers, building types, buildings, etc., can solve the problems of felling or destruction of surrounding plants, soil erosion or slippery, and hidden dangers of wind power towers, so as to facilitate processing and reduce basic consumables. The effect of shortening the construction period with earthwork engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

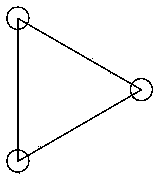

[0027] A wind power tower with long and short legs includes three outriggers 2 of different lengths, and the outriggers are arranged at intervals at the bottom of the tower. A triangular distribution is adopted between the three supporting legs. The installation angle of the outriggers at the bottom of the tower may continue to extend downward along the inclination of the tower, and the connection between the outriggers and the tower body may be a fixed connection. The tower above the outriggers of the wind power tower It is a lattice structure.

[0028] The parts not described in this embodiment are the same as the prior art.

Embodiment 2

[0030] The parts not described in this embodiment are the same as those in Embodiment 1, except that the body of the tower is composed of upper and lower parts. On the legs, the legs are distributed in a quadrilateral shape.

[0031] The parts not described in this embodiment are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com