Suspended type concrete pouring chuting device

A concrete, suspended technology, applied in the construction, building structure, construction material processing and other directions, can solve the problems of inability to pour, limited height of the support, large manpower, materials and time, etc., to achieve easy installation and disassembly, simple structure , the effect of low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing and embodiment, the specific implementation manner of the patent of the present invention is described in further detail. The examples are used to illustrate the present invention, but not to limit the scope of the present invention.

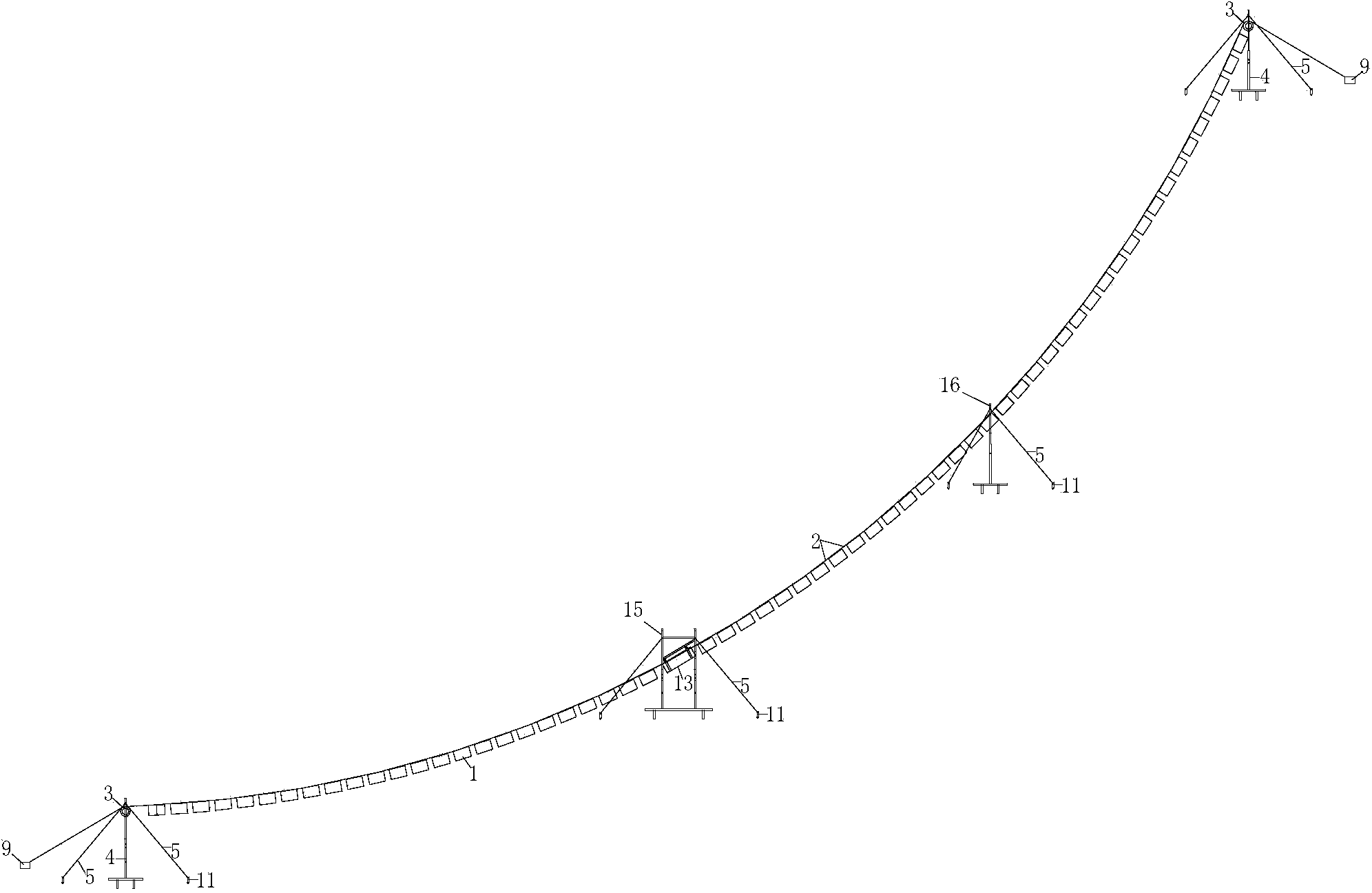

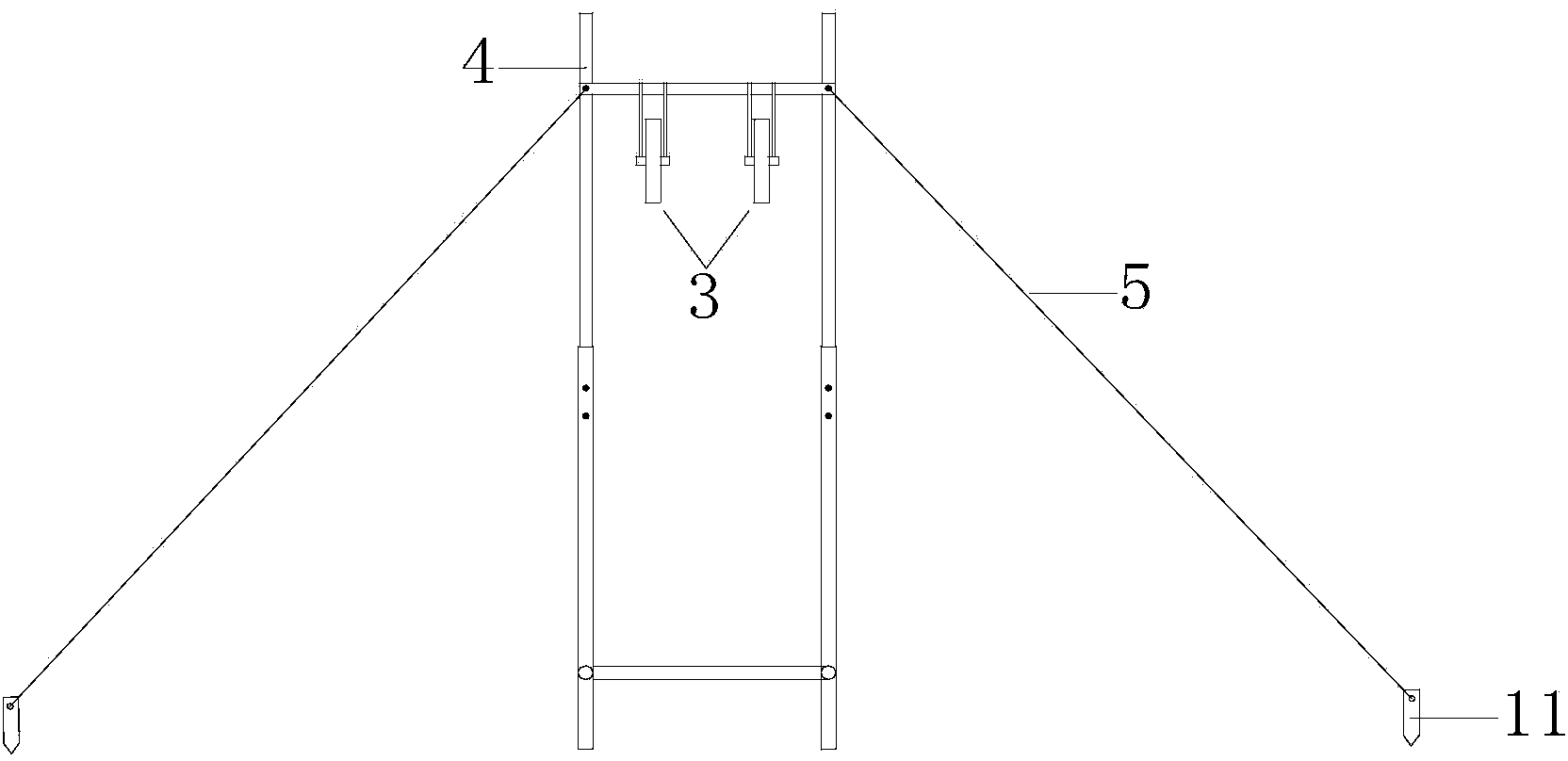

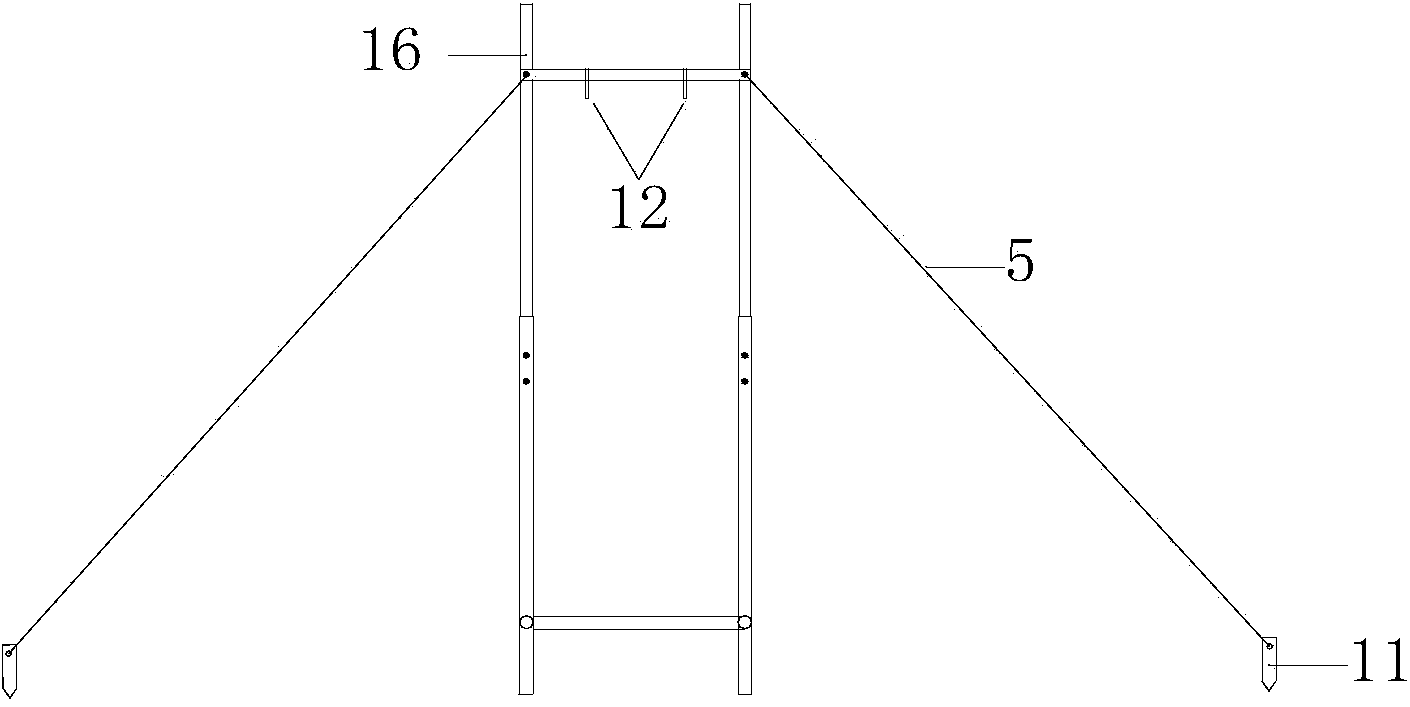

[0036] see figure 1 , figure 2 and Figure 5 , a suspended concrete pouring chute device, including at least two supports 4, on which a pulley 3 is connected, and a sling 2 is connected between the two supports 4, and the sling 2 can be a metal sling or a synthetic fiber sling slings; slings 2 are arranged in parallel, and the number of slings can be one, two or more. The sling 2 passes through the pulley 3 and is connected with the tensioning equipment 9, and the tensioning equipment 9 is an electric hoist, a chain hoist or a hoist. A plurality of locks 6 are fixed on the sling 2 at intervals, and a plurality of short chute sections 1 are also included. The short chute sections 1 are hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com