A kind of high-phosphorus organic foliar fertilizer for organic agricultural product production and preparation method thereof

A technology for foliar fertilizers and agricultural products, which is applied to high-phosphorus organic foliar fertilizers for the production of organic agricultural products and its preparation, and the field of organic foliar fertilizers, can solve problems such as poor adaptability and lack of phosphorus nutrition, and achieve a short and effective time. High phosphorus content and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

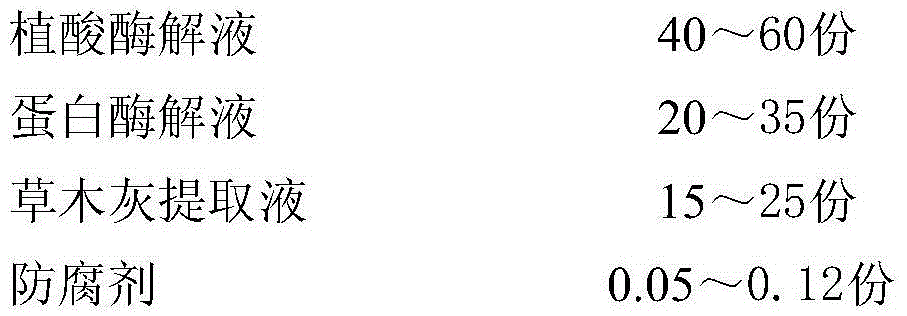

[0043] Embodiment 1: a kind of high-phosphorus type organic foliar fertilizer, composition is as follows:

[0044]

[0045] The preparation method is as follows:

[0046] (1) Take 50 kg of corn germ, add 150 kg of water, boil for 10 minutes, adjust the pH value to 5.0 after cooling, add 0.08 kg of a mixture of phytase preparations SUKAPhyPW5 and SUKAPhyPW4 in a mass ratio of 1:1, stir evenly, and store at 56°C Place it under the same conditions for 2.5 hours, stir once every 0.5 hours during this period, each time for 3 minutes, squeeze and filter after the end, and obtain two parts: liquid and solid;

[0047](2) Take 40 kg of solid matter obtained in step (1), add 50 kg of water, adjust the pH value to 7.0, add 0.1 kg of neutral protease preparation SUKAPro NEPW50, stir for 3 minutes, and place it at 50°C for 2 hours. Stir once in half an hour, 2 minutes each time, squeeze and filter after the end to obtain protein enzymatic hydrolyzate; set aside;

[0048] (3) Get 20 kg...

Embodiment 2

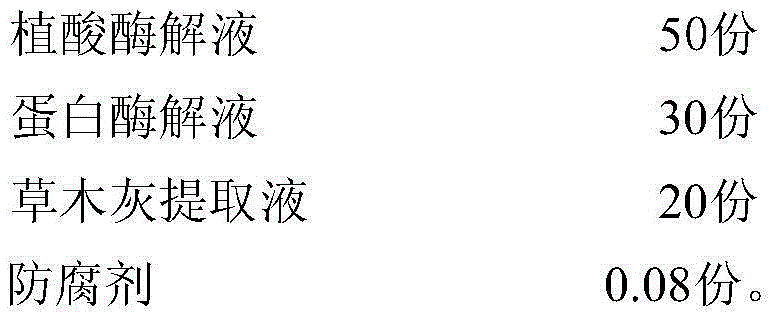

[0050] Embodiment 2: a kind of high phosphorus type organic foliage fertilizer, composition is as follows:

[0051]

[0052] The preparation method is as follows:

[0053] (1) Take 40 kg of corn germ, add 200 kg of water, boil for 5 minutes, adjust the pH value to 5.2 after cooling, add 0.05 kg of SUKAPhyPW5 phytase preparation, stir well, and place it at 60°C for 2 hours, during which every 0.5 Stir once every hour, 3 minutes each time, squeeze and filter after the end, and get two parts of liquid and solid respectively; the liquid is used as phytic acid enzymatic hydrolysis solution, and set aside;

[0054] (2) Take 30 kg of solid matter obtained in step (1), add 60 kg of water, adjust the pH value to 7.2, add 0.05 kg of neutral protease preparation SUKAPro NE PW30, stir for 2 minutes, and place it at 45°C for 3 hours. Stir once every half hour, 2 minutes each time, squeeze and filter after the end, to obtain proteolytic solution; set aside;

[0055] (3) Get 15 kg of pl...

Embodiment 3

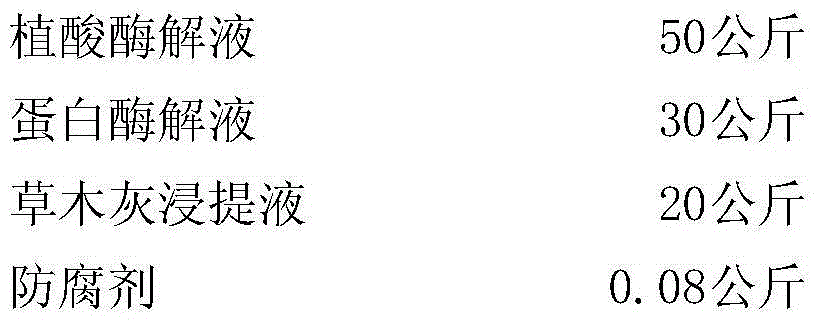

[0057] Embodiment 3: a kind of high phosphorus type organic foliage fertilizer, composition is as follows:

[0058]

[0059] The preparation method is as follows:

[0060] (1) Take 45 kg of corn germ, add 100 kg of water, boil for 15 minutes, adjust the pH value to 4.8 after cooling, add 0.1 kg of SUKAPhyPW4 phytase preparation, stir well, and place it at 50°C for 2.8 hours, during which every 0.5 Stir once every hour, 3 minutes each time, squeeze and filter after the end, and get two parts of liquid and solid respectively; the liquid is used as phytic acid enzymatic hydrolysis solution, and set aside;

[0061] (2) Take 35 kg of solid matter obtained in step (1), add 45 kg of water, adjust the pH value to 6.5, add 0.08 kg of neutral protease preparation SUKAPro NE PW30 and SUKAPro NE PW50 in a 1:1 mass ratio mixture, and stir for 5 minutes , placed at 55°C for 2.5 hours, stirring once every half an hour, 2 minutes each time, after the end, squeeze and filter to obtain prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com