Ampoule fixed-distance conveying device

A technology for conveying devices and ampoules, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc. It can solve the problems of unfavorable ampoule cleaning, filling efficiency and equipment investment and maintenance costs, and achieves simple structure and easy operation , the effect of occupying less land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

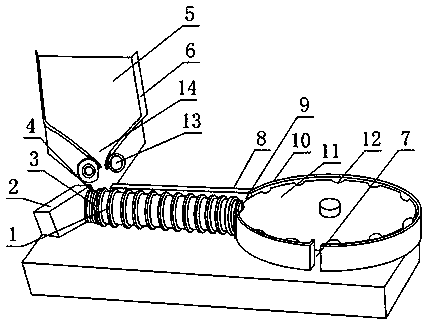

[0021] like figure 1 , the ampoule fixed-distance conveying device provided by the present invention includes an ampoule accommodating device and an ampoule conveying mechanism. 6. The lower ends of the ribs 6 are close together to form the ampoule release port, and the ampoule release port 14 is also provided with a cam 13 for adjusting its opening size, and the cam 13 is located outside the ampoule release port 14 , the cam 13 is in contact with any one of the ribs 6, and the ampoule conveying mechanism includes a transmission shaft 4 arranged below the ampoule release port, a helical shaft sleeved on the transmission shaft 4 and arranged along the axial direction of the transmission shaft 4 The spiral guide rail 1, the driving part 2 connected to one end of the transmission shaft 4, and the turntable 11 arranged at the other end of the transmission shaft 4, the turntable 11 is provided with a plurality of receiving grooves 12 that are evenly distributed in a ring shape, and...

Embodiment 2

[0024] This embodiment is further limited on the basis of embodiment 1: as figure 1 , in order to prevent the ampoule from slipping from the spiral guide rail 1, which affects the stability of the present invention for transporting the ampoule, it also includes a guide plate 8 arranged on one side of the transmission shaft 4, and the guide plate 8 is parallel to the transmission shaft 4. In the above settings, preferably the bottle body of the ampoule rides on the transmission shaft 4, the bottom of the ampoule is in contact with the guide plate 8, and the inclination of the guide plate 8 and its distance from the transmission shaft 4 are preferably such that the bottom of the ampoule is in contact with the guide plate 8. The height is less than the height of the bottle mouth.

Embodiment 3

[0026] The present embodiment is further limited on the basis of embodiment 1: as figure 1 , in order to make the ampoule placed between the bottom plate 5 and the rib 6 stably, and smoothly fall freely from the ampoule release port under the action of its own weight, the inclination angle of the bottom plate 5 relative to the horizontal plane is in the range of 60° to 75° Inside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com