New detachable refillable spray bottle

A liquid spray bottle and detachable connection technology, applied in the field of liquid spray bottles, can solve the problems of consumers losing confidence in product quality, failure of sealing and liquid filling functions, unstable product quality, etc. The complexity of the shape, the improvement of the reliability of the liquid inlet, the effect of the simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

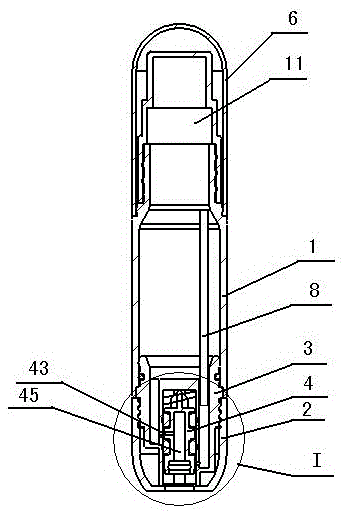

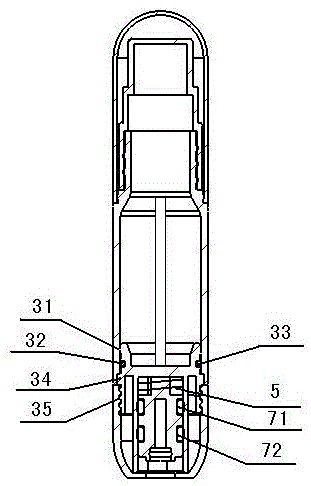

[0030] Such as figure 1 , 3 As shown, the liquid spray bottle is composed of three parts as a whole, including a bottle cap 6, a bottle body 1 and a bottle bottom 2, the bottle body 1 and the bottle bottom 2 are detachably connected by a valve seat 3, and the upper part of the bottle body 1 is threaded with the bottom of the bottle. The nozzle assembly 11 is connected, and the outer cover is provided with a plastic or metal bottle cap 6, and the metal bottle cap 6 is connected with the bottle body 1 in a ferrule type. When carrying, the bottle cap can prevent the nozzle assembly from being squeezed and the bag from getting wet. The body of the bottle is made of transparent material, or one side is made of transparent material, so that it is convenient to observe the remaining liquid in the inner bottle at any time to determine whether it needs to be filled.

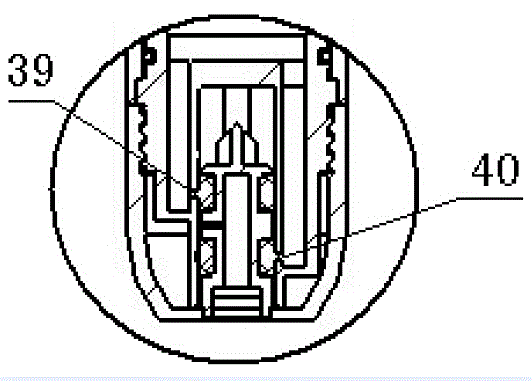

[0031] Such as figure 1 , 3 , 4, 5, and 6, the valve seat 3 is an integrated valve seat, and its outer wall is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com