Tubular-elastic part clamping device

A clamping device and elastic technology, applied in the field of clamping devices, can solve the problems of no clamping device, etc., and achieve the effect of simple structure, convenient use, and firm clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

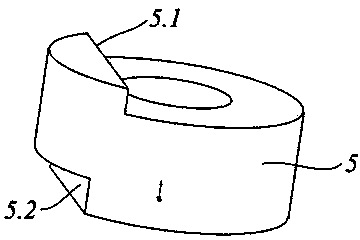

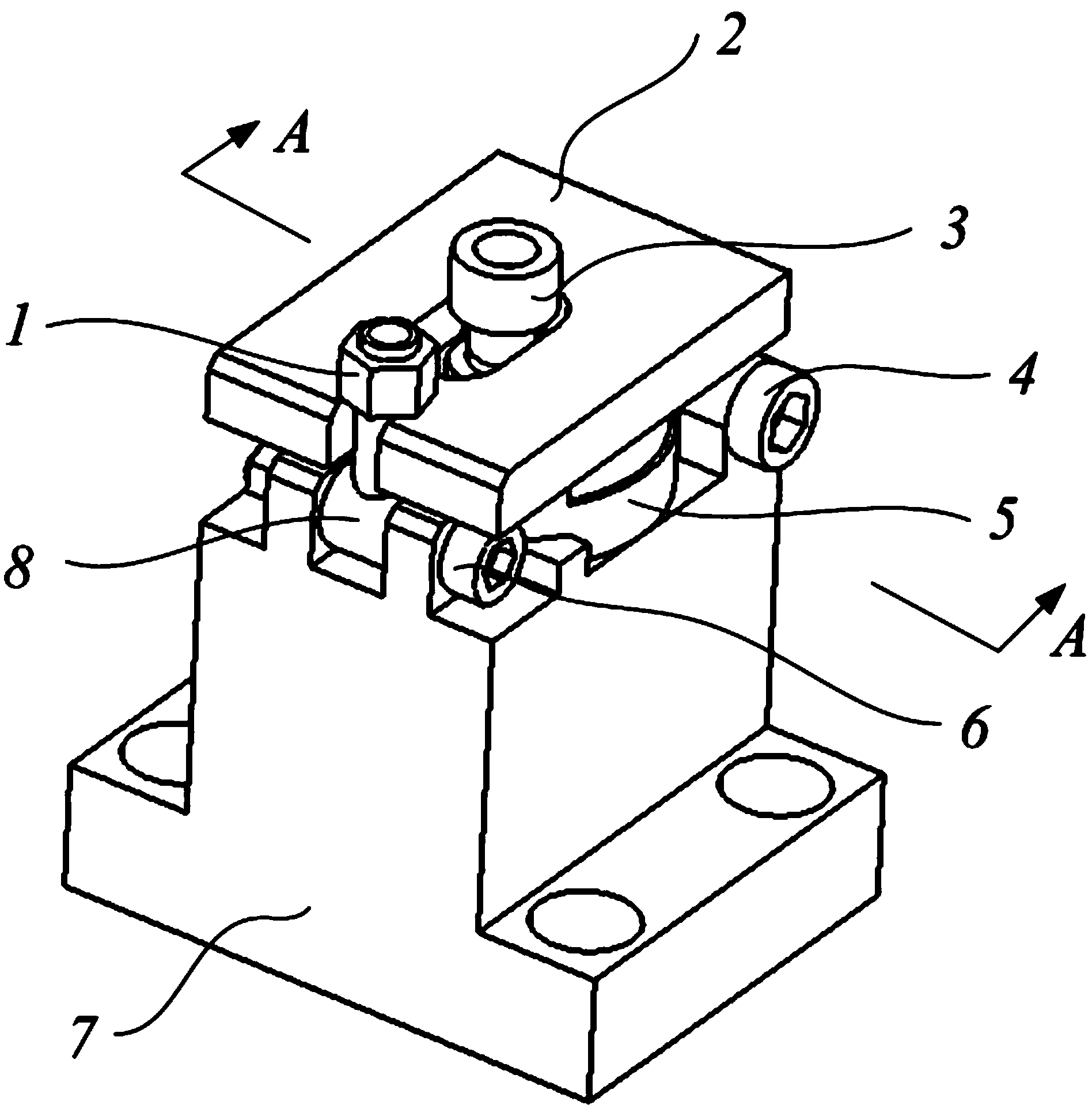

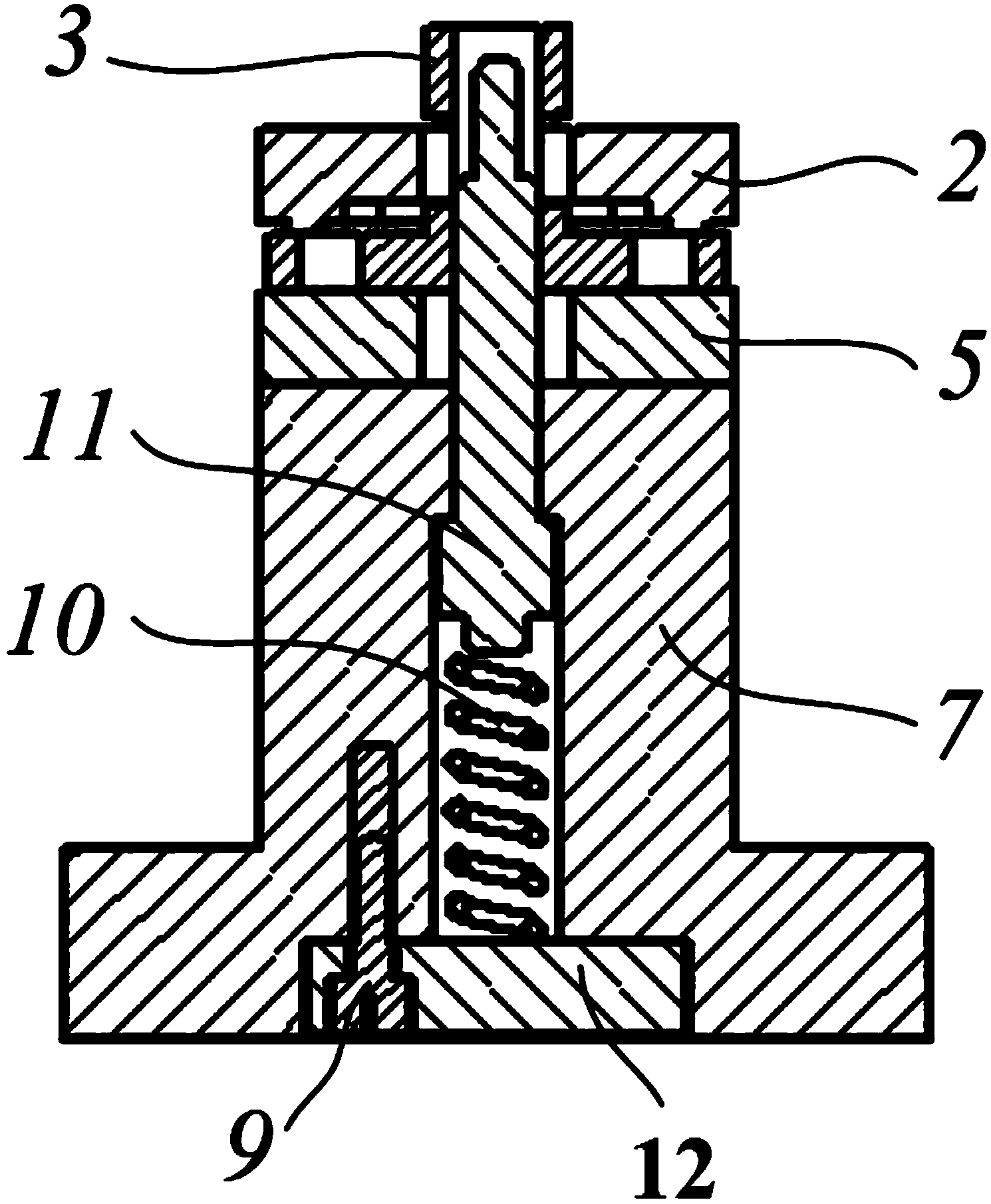

[0034] figure 1 Shown is a schematic diagram of the mechanism of the tubular elastic part clamping device of the present invention, including a quick-opening nut 1, a pressing plate 2, a pressing plate rotating shaft 4, a part pad 5, a quick-opening rotating screw rotating shaft 6, a base 7 and a quick-opening rotating shaft Screw 8. The ground of tubular elastic part 3 is placed on the upper surface of spacer 5 (see image 3 shown). The inner surface of the upper end of the spacer is in contact with the side plane of the tubular elastic part 3, and the outer surface 5.2 of the lower end of the spacer is in contact with the stopper 7.1 of the base to realize the lateral fixing function of the part (see Figure 5 shown). Among them, there are two rotating shaft holes on the upper part of the base 7, which are respectively matched with the shafts 4 and 6 to realize the quick opening of the pressure plate 2 and the quick-opening rotary screw 8; in addition, the inside of this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com