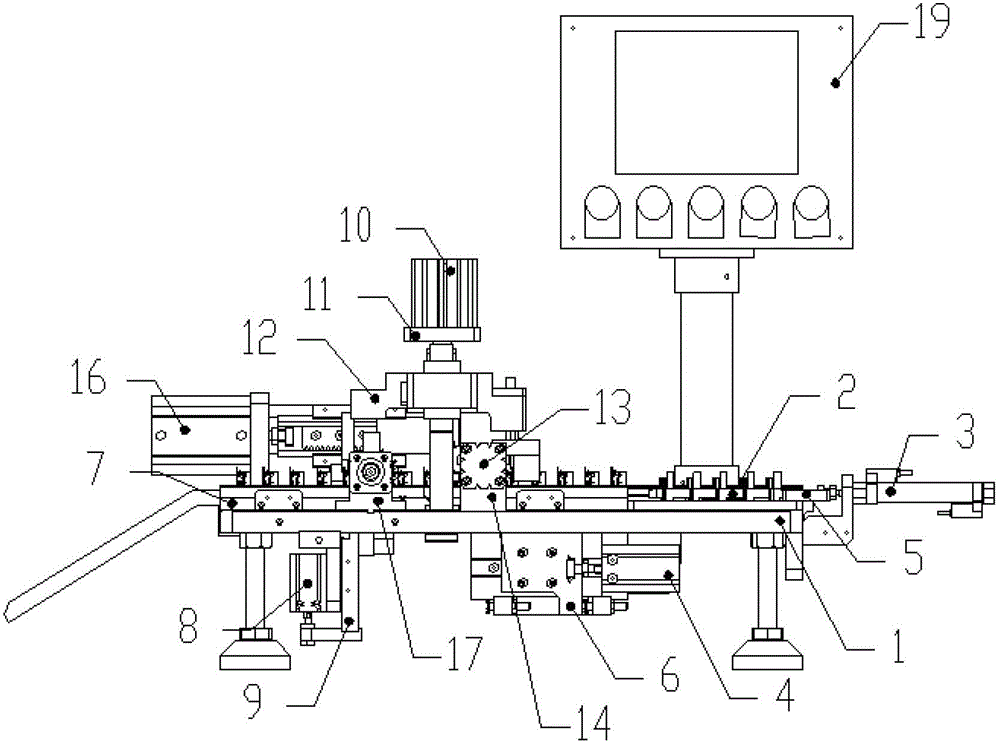

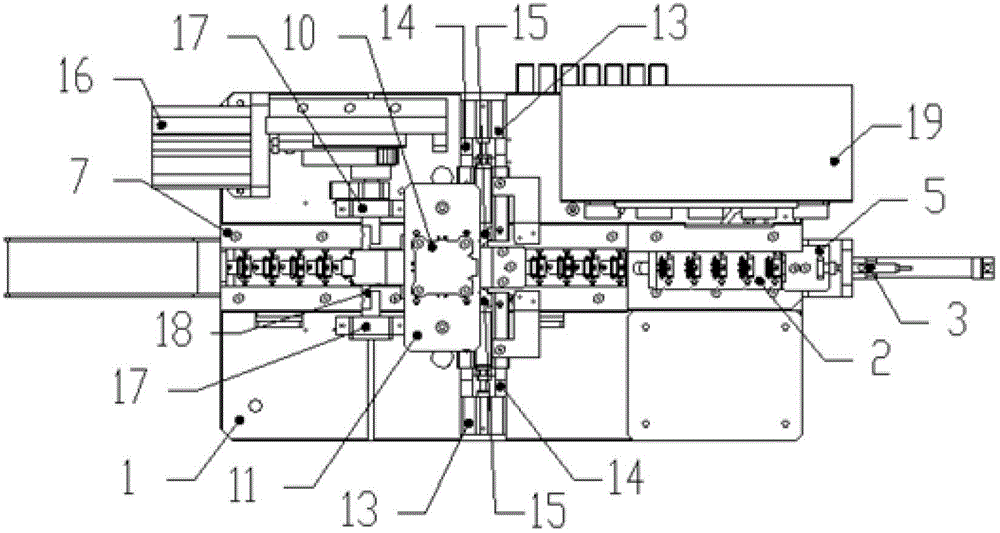

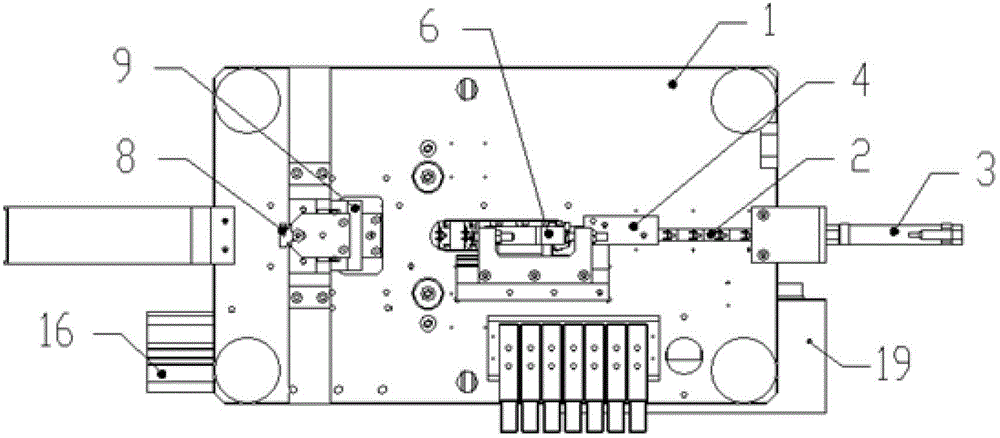

Press-in riveting equipment

A riveting and equipment technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of low work efficiency, company increase, large labor cost, etc., and achieve accurate riveting position, fast riveting speed, and production low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] Embodiment: A press-in riveting equipment, including a frame 1, a carrier 2, a carrier pushing device, a carrier pushing driving device, a carrier pushing and positioning flow channel 7, a carrier positioning driving device 8, and a carrier positioning device 9. The pressing material shaping drive device 10, the pressing material shaping device 12, the dislocation riveting driving device 13, the dislocation riveting block 15, the rotating riveting driving device 16, the rotating riveting block 18 and the controller 19, the carrier pushes The positioning flow channel 7 is installed through the frame 1, and the carrier pushing drive device can drive the carrier pushing device to transport the carrier located at the entrance of the carrier pushing and positioning flow channel 7 along the carrier pushing and positioning flow channel 7, and the carrier is positioned The driving device 8 can drive the carrier positioning device 9 to fix and position the carrier on it. A pair o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com