Two-sided casting mold for steel section stack boxes

A technology for casting molds and stacking boxes, which is used in manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of high labor intensity, short service life, low production efficiency, etc., to reduce production costs, avoid bubbles and cracks , the effect of reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

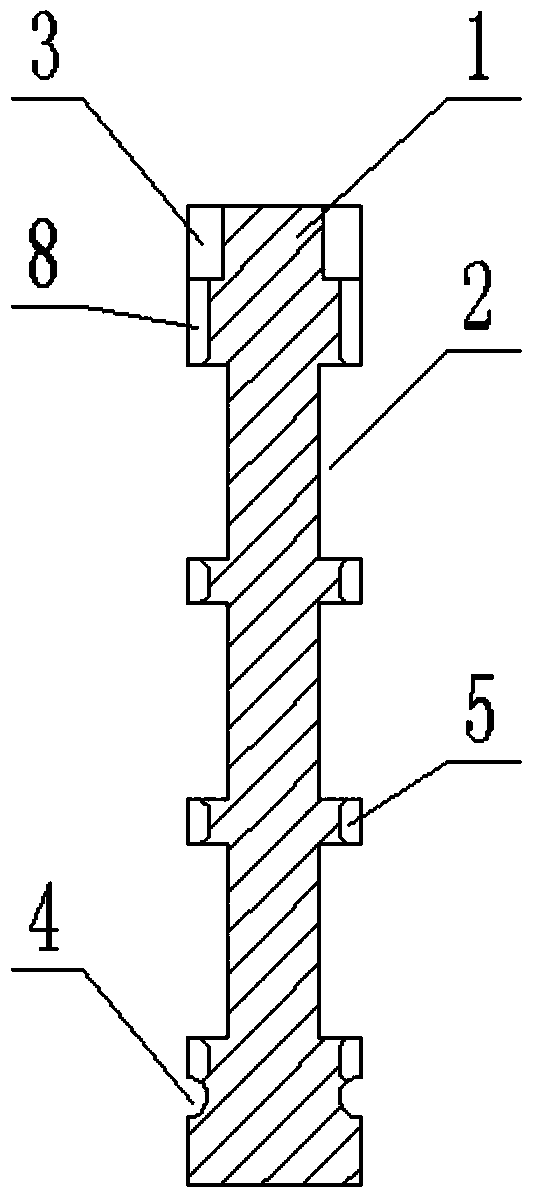

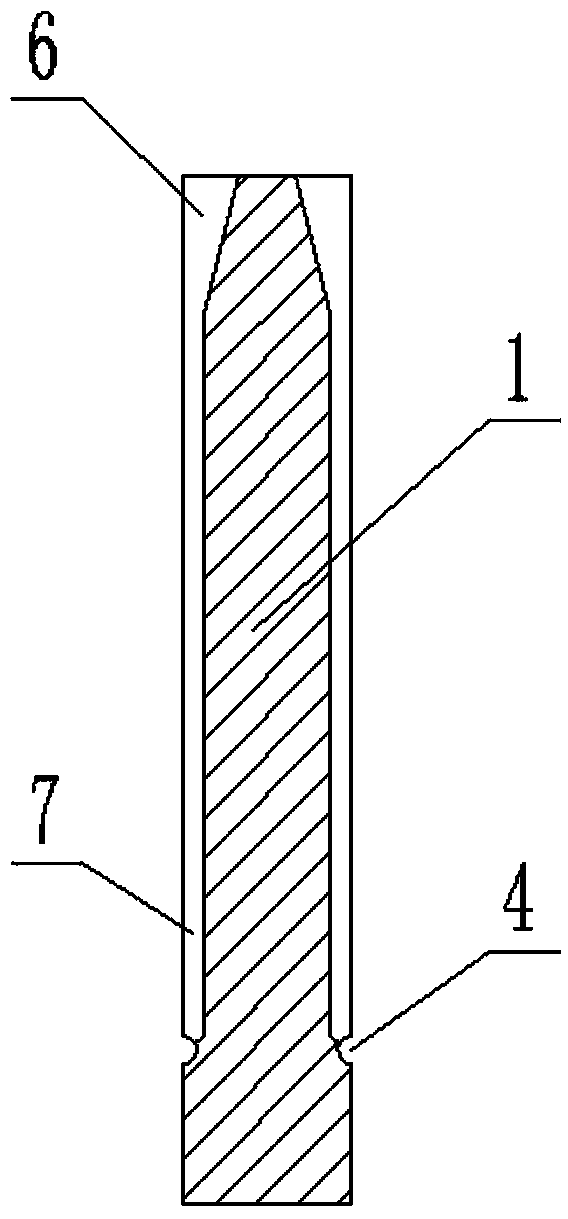

[0037] Embodiment 1: When a group of steel segments needs to be produced, it is the same as conventional casting at this time, that is, two modular monomers 1 are used for casting. Close the two modular monomers 1, at this time, the cavity 2, sprue 7, sprue 6, runner 4, ingate 5, overflow port 8 and overflow between the two modular monomers 1 The grooves 3 are closed one by one to form a complete casting channel, cavity and overflow channel; the molten iron is injected into the module body 1 through the two pouring ports 6, and the gas in the cavity moves upward and is discharged through the overflow port 8 , Bottom injection casting, molten iron flows upward from the runner 4 at the bottom, and fills the cavity 2 one by one. When the molten iron overflows from the overflow port 8 into the overflow tank 3, the cavity 2 is completely filled with molten iron. After the molten iron is cooled, disassemble the module unit 1 and take out the rough mold. Since the ends of the ingate ...

Embodiment 2

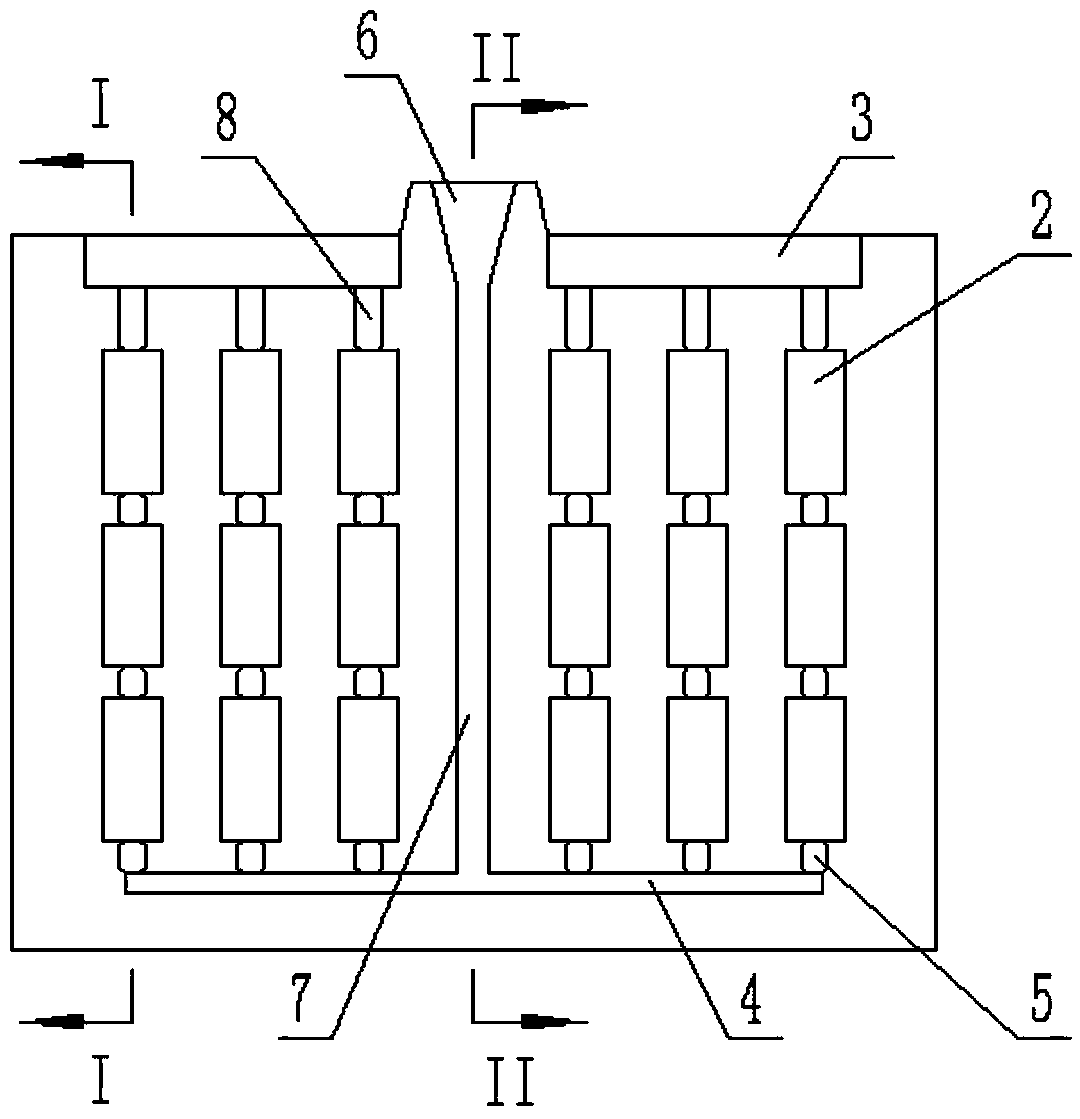

[0038] Embodiment 2: When it is necessary to produce multiple sets of steel sections, it is assumed that the number of module monomers 1 is S, and the number of steel section groups is n, that is, S=n+1, n=1, 2, 3... ..n. Taking two groups of steel segments as an example, such as Figure 4 As shown, the three modular monomers 1 are superimposed in sequence. At this time, the two sides of the middle module monomer 1 form a complete casting channel, cavity 2 and overflow channel respectively, that is, two sides of the middle module monomer 1 form two A complete casting system; inject molten iron into the three module bodies 1 through two complete casting ports 6, and the gas in the cavity 2 is discharged upwards through the overflow port 8, bottom injection casting, and the molten iron is poured horizontally from the bottom The channel 4 flows upwards and fills the complete cavity 2 one by one. When the molten iron overflows from the overflow port 8 into the overflow groove 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com