Device and method for measuring thickness of lubricating oil film on high-speed rolling interface

A technology of thickness measurement and lubricating oil film, which is applied in the direction of length measuring device, metal rolling, metal rolling, etc., can solve the problems that have not been well solved, are not applicable to the measurement of oil film thickness at the rolling interface, and have a great influence on the thickness of lubricating oil film, etc. problems, to achieve the effect of simple structure, accurate results, and elimination of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

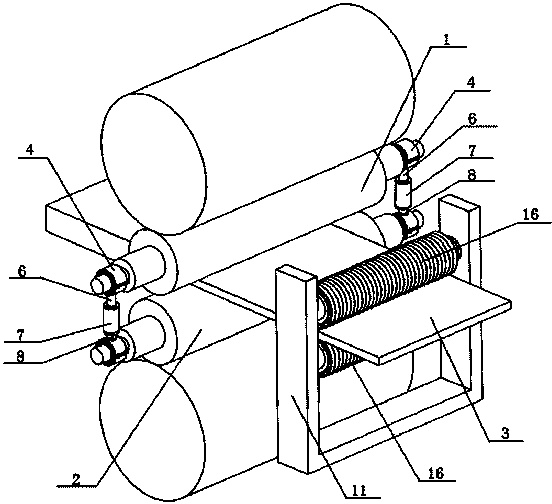

[0026] Such as figure 1 As shown, the present invention includes a dynamic roller center distance measuring device, a plate thickness measuring device, and a data processing and display device. The dynamic roll center distance measuring device can accurately measure the distance between the upper and lower work rolls, and the plate thickness measuring device can measure the thickness change of the plate in the longitudinal and transverse directions. After obtaining the distance between the center of the upper and lower work rolls and the thickness of the plate, the change in the thickness H of the lubricating oil film at the rolling interface can be obtained after processing by the data processing module.

[0027] Such as figure 2 and 3 As shown, the dynamic roller center distance measuring device is composed of a bearing 5 , a bearing sleeve 4 , a push rod 6 , a connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com