A kind of production method of modified casein

A production method and technology of casein, which is applied in the field of production of modified casein, can solve problems such as poor solubility and bad smell of products, and achieve the effects of improving stringiness, good solubility characteristics, and good fluidity of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

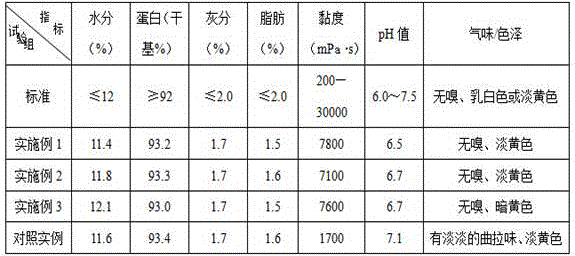

Embodiment 1

[0015] 1 Raw material characteristics: Qula casein is used as raw material. The physical and chemical indicators of Qula casein are 93.4% protein, 1.6% fat and 1.7% ash.

[0016] 2. Extrusion and puffing: add koji casein into the extruder at a uniform speed, add 8% of its mass purified water at the same time, make koji casein and purified water at a temperature of 120°C and screw speed Extrusion and puffing are carried out in a 450r / min extruder, and the extrusion conversion time is controlled at 20s.

[0017] 3. Pulverization: place the expanded casein on the conveyor belt, let it cool naturally, dry it, and then enter the pulverizer to obtain the modified casein powder product.

Embodiment 2

[0019] 1 Raw material characteristics: Qula casein is used as raw material. The physical and chemical indicators of Qula casein are 92% protein, 1.6% fat and 1.8% ash.

[0020] 2. Extrusion and puffing: add koji casein into the extruder at a uniform speed, add 12% of its mass purified water at the same time, make koji casein and purified water at a temperature of 130°C and screw speed Extrusion and puffing are carried out in a 400r / min extruder, and the extrusion conversion time is controlled at 25s.

[0021] 3. Pulverization: place the expanded casein on the conveyor belt, let it cool naturally, dry it, and then enter the pulverizer to obtain the modified casein powder product.

Embodiment 3

[0023] 1 Raw material characteristics: Qula casein is used as raw material. The physical and chemical indicators of Qula casein are 93.4% protein, 2.0% fat and 1.7% ash.

[0024] 2. Extrusion and puffing: Add koji casein into the extruder at a uniform speed, and add 15% of its mass purified water at the same time, so that the koji casein and purified water can be mixed at a temperature of 110°C and the screw speed Extrusion and puffing are carried out in a 420r / min extruder, and the time is controlled at 25s.

[0025] 3. Pulverization: place the expanded casein on the conveyor belt, let it cool naturally, dry it, and then enter the pulverizer to obtain the modified casein powder product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com