Single-stage power factor correction LED accurate constant current driving circuit

A technology of power factor correction and constant current drive, applied in electric lamp circuit arrangement, electric light source, lighting device, etc., can solve the problems of large output current fluctuation, not long life, large size, etc., to achieve constant output current and low cost , to ensure the effect of power factor and low harmonic current control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

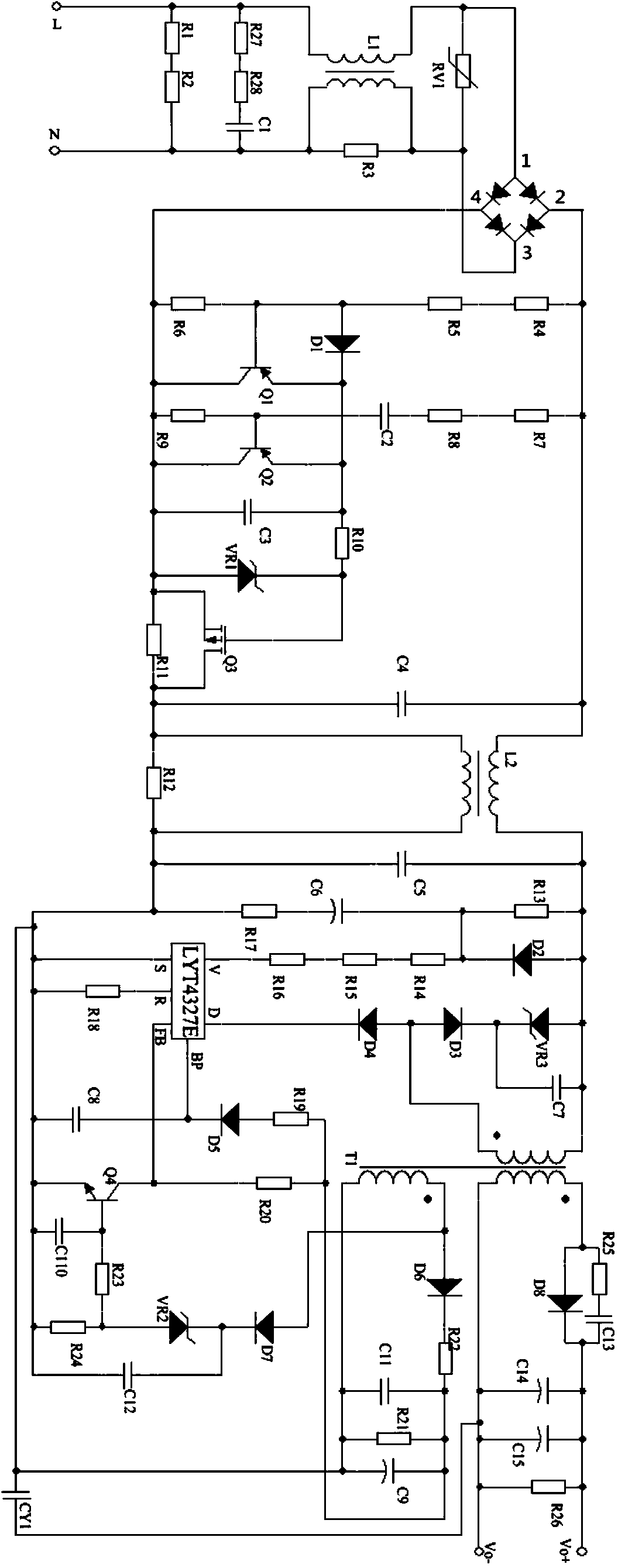

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

[0012] A single-stage power factor correction LED accurate constant current drive circuit, including a passive RC discharge circuit, an EMI filter circuit, a rectification filter circuit, an active attenuation circuit, a switch control circuit, a DC conversion filter circuit, and a passive RC discharge circuit Connect the input of the EMI filter circuit, the output of the EMI filter circuit to the input of the rectification filter circuit, the output of the rectification filter circuit to the input of the active depletion circuit, the output of the active depletion circuit to the input of the switch control circuit, and the output of the switch control circuit to the DC conversion filter circuit.

[0013]With reference to accompanying drawing, described passive RC discharge circuit comprises resistance R1, resistance R2, resistance R27, resistance R28, electric capacity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com