Novel double-stator low-pulsating-torque stepping motor

A stepper motor, pulsating torque technology, applied in the direction of motor generator control, electrical components, electromechanical devices, etc., can solve the problems of front and rear vibration of displacement, vibration of stepper motor, fluctuation (resonance or jitter, etc.)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The structural features of the double-stator low-pulsation torque stepping motor of the present invention will be further described below in conjunction with the accompanying drawings.

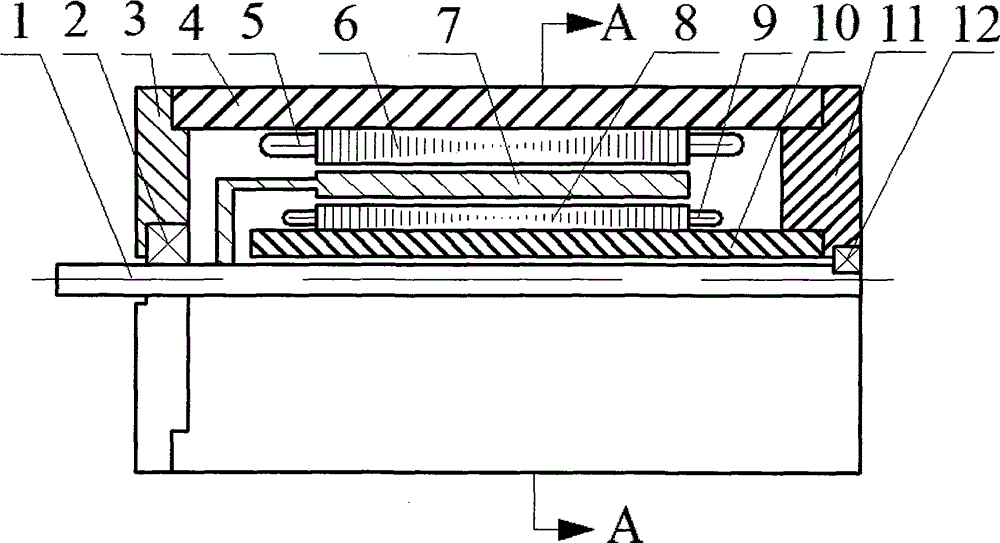

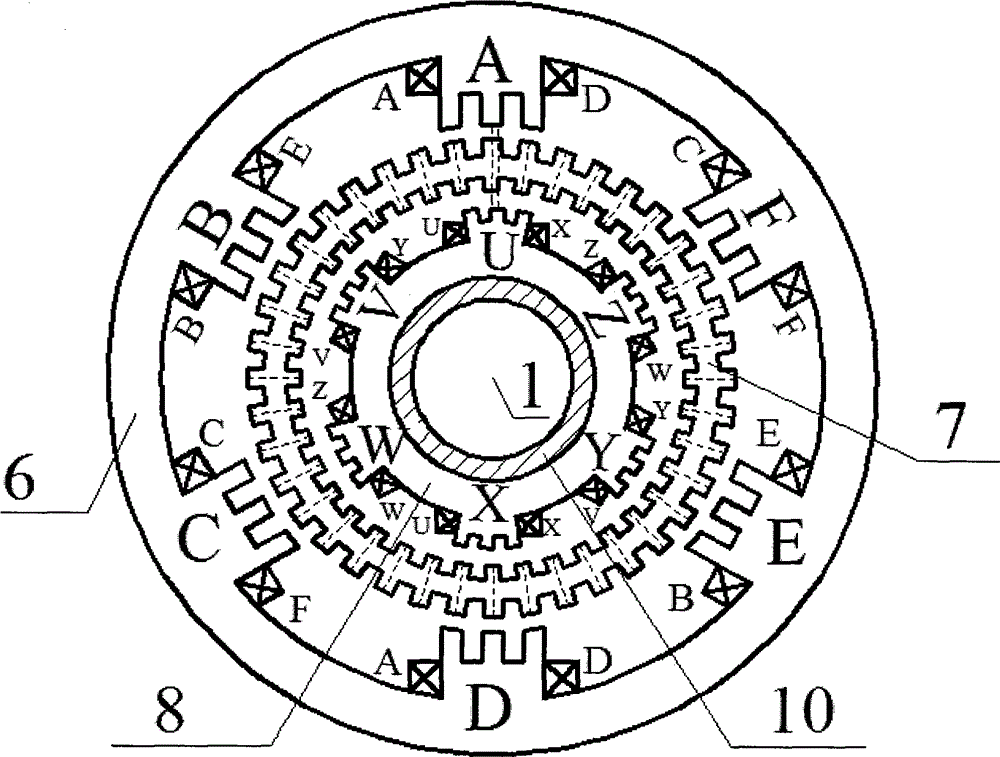

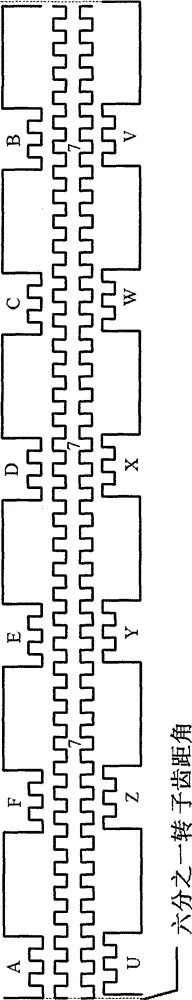

[0026] figure 1 It is a structural schematic diagram of a double-stator low-pulsation torque stepping motor of the present invention, including a motor shaft 1, a bearing 2, a front cover 3, a casing 4, an outer stator three-phase symmetrical concentrated winding 5, an outer stator core 6, and a cup-shaped rotor 7 , inner stator core 8, inner stator three-phase symmetrical concentrated winding 9, inner stator sleeve 10, rear end cover 11 and bearing 12.

[0027] The front end cover 3 is located at the front end of the casing 4, the rear end cover 11 is located at the rear end of the casing 4, the motor shaft 1 passes through the center of the front end cover 3 and the rear end cover 11, and the bearing 2 is placed between the motor shaft 1 and the front end cover 2 The bearing 12 is pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com