Heat sensor with driving function

A thermal sensor and functional technology, applied in the field of thermal sensors with driving function, can solve the problems of thermocouples not resistant to flame ablation, hidden dangers, potential difference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

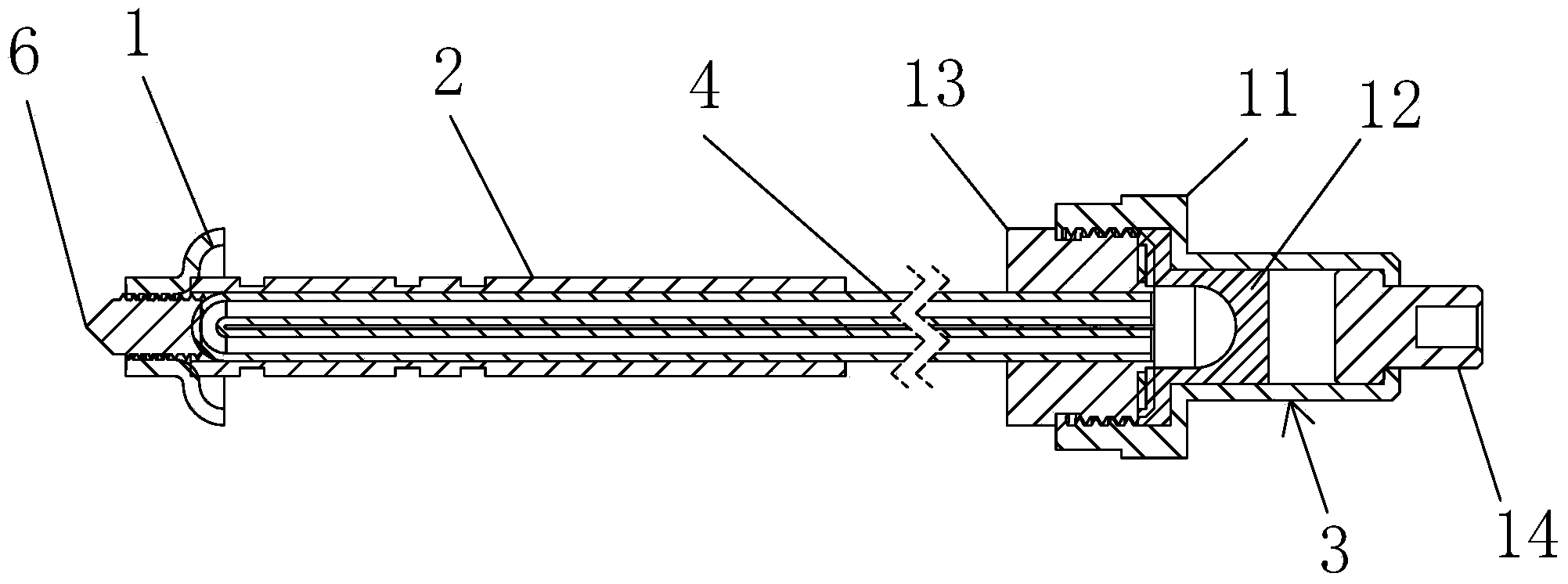

[0034] A thermal sensor with driving function of the present invention will be described in detail below with reference to the embodiments and the accompanying drawings.

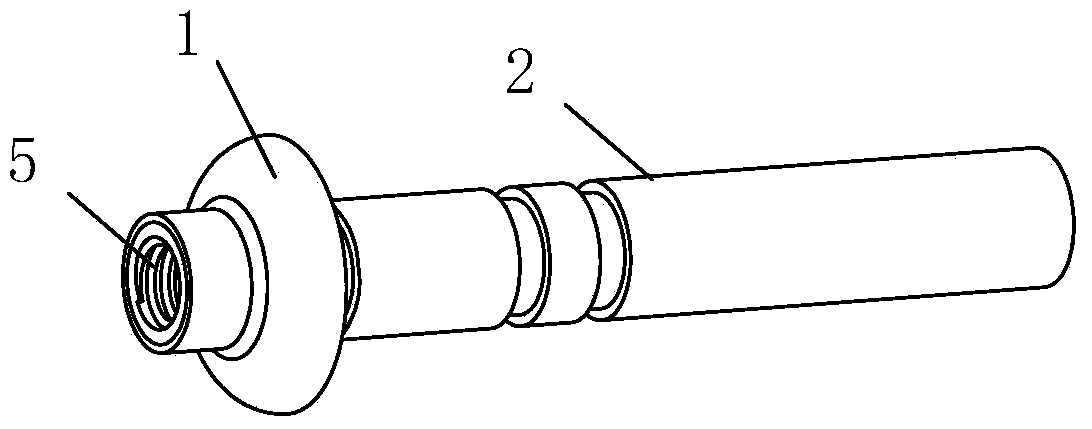

[0035] like figure 1 , image 3 As shown, a thermal sensor with driving function of the present invention includes: one end is provided with a sleeve cap 1 and the other end is an open sleeve 2, a driving cylinder 3, and one end from the open end of the sleeve 2 Inserted into the sleeve 2, the other end is connected to the U-shaped pipe 4 of the cylinder 3, the center of the sleeve cap 1 is formed with a sleeve internal thread 5 penetrating with the sleeve 2, and the sleeve cap 1 passes through the The sleeve internal thread 5 described above is connected with a heat collecting needle 6 for absorbing heat source.

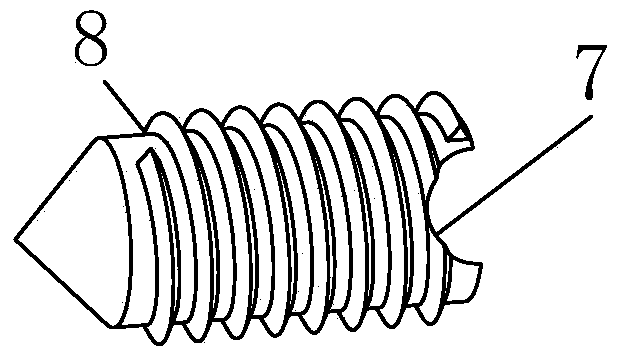

[0036] like figure 2 As shown, one end of the heat collecting needle 6 is a tapered structure, and the other end is formed with a heat collecting needle inner arc 7 for combining with the end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com