Two-way thrust-free directly-buried compensator

A direct-buried type compensator technology, which is applied in expansion compensation devices for pipelines, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of small compensation amount and single-directional installation, and achieve large compensation amount, Effects of improving reliability and improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

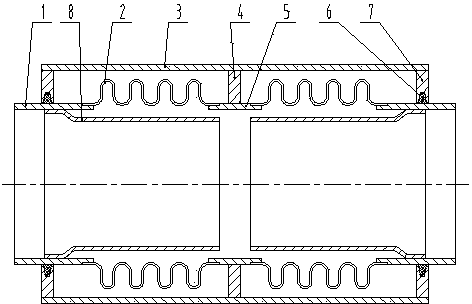

[0012] The two-way non-thrust direct-buried compensator shown in the attached figure includes an end pipe 1, two bellows 2, an intermediate pipe 5 and a guide tube 8; the intermediate pipe 5 is connected to the bellows 2 and the end pipe 1 in sequence , forming a double bellows compensation structure; a protective cover 3 is provided outside the double bellows compensation structure; the protective cover 3 and the intermediate connecting pipe 5 are fixedly connected by a fixing ring 4; both ends of the protective cover 3 are fixedly connected to the end plate 7, and the end The gap between the plate 7 fits on the outer wall of the terminal pipe 1. In this embodiment, the inner hole wall of the end plate 7 is provided with a radial annular groove, and a sealing ring 6 is arranged in the radial annular groove, which is close to the outer w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com