A straight travel bracket

A straight-travel, straight-travel technology, applied in the field of valve connecting brackets, can solve the problems of ugly appearance, high cost, cumbersome adjustment, etc., and achieve the effect of simple overall structure, improved service life, and smooth running process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

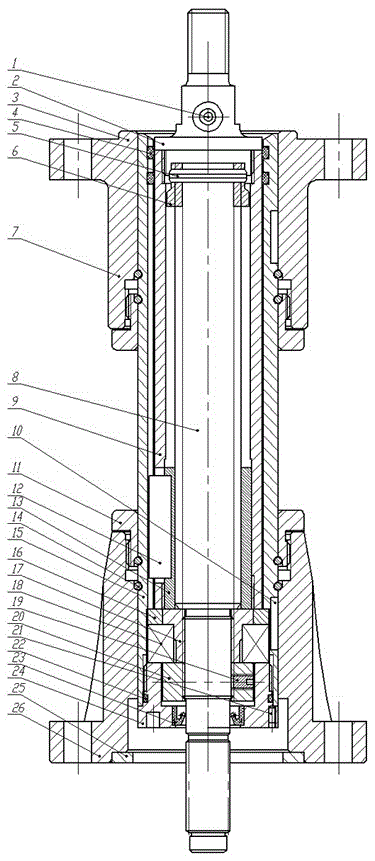

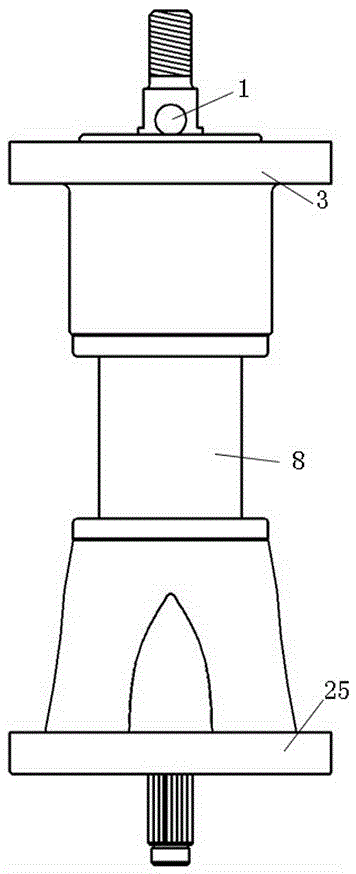

[0012] This embodiment is a straight-stroke bracket, including an upper flange (3), a lower flange (25), a sleeve (14), and a driving part; the top of the straight-stroke bracket is provided with an upper flange (3) , the bottom end is provided with a lower flange (25), the middle part is a driving part, and the driving part includes a driving sleeve (12), a main shaft (7), a fixing ring (19), a straight rod (8), and a connecting end cover (2); where the connecting end cover (2) is connected with the valve stem and fixed on the top of the straight rod (8), the main shaft (7) and the drive sleeve (12) are connected by left-handed trapezoidal thread and fixed on the sleeve by a flat key Inside (14), there is a long keyway inside the sleeve (14), so that the straight rod (8) assembly can only move up and down along the keyway to realize the opening and closing of the valve. The drive sleeve (12) and the main shaft (7) The connection is threaded, and the thread is a left-handed tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com