Cooling mixer upper cover sealing structure

A technology for cooling a mixer and a sealing structure, which is applied in the directions of mixers, engine sealing, mechanical equipment, etc., can solve the problems of poor cylinder sealing, complex manufacturing process, poor sealing, etc., and achieves simple manufacturing process and cost. Low, better sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

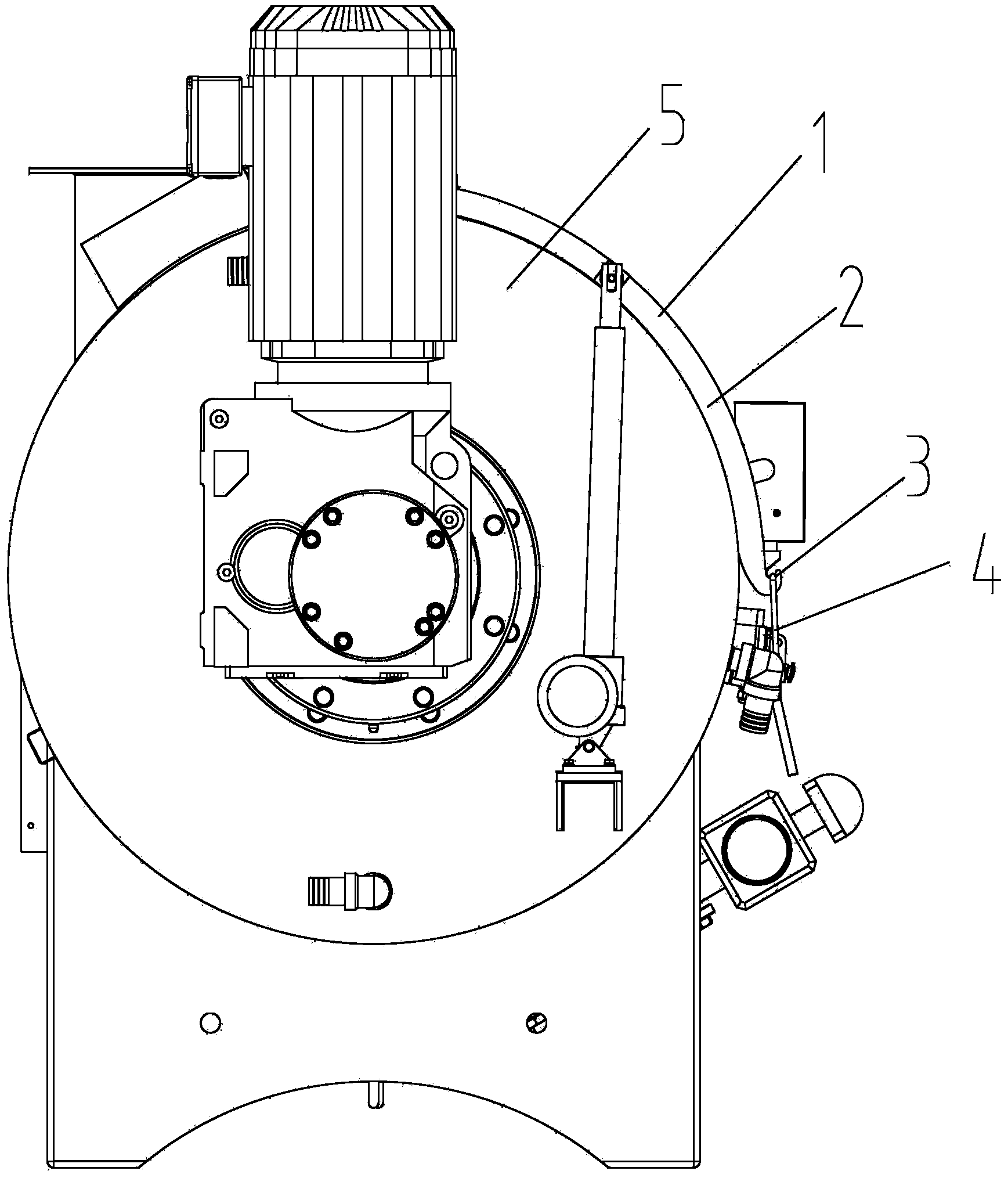

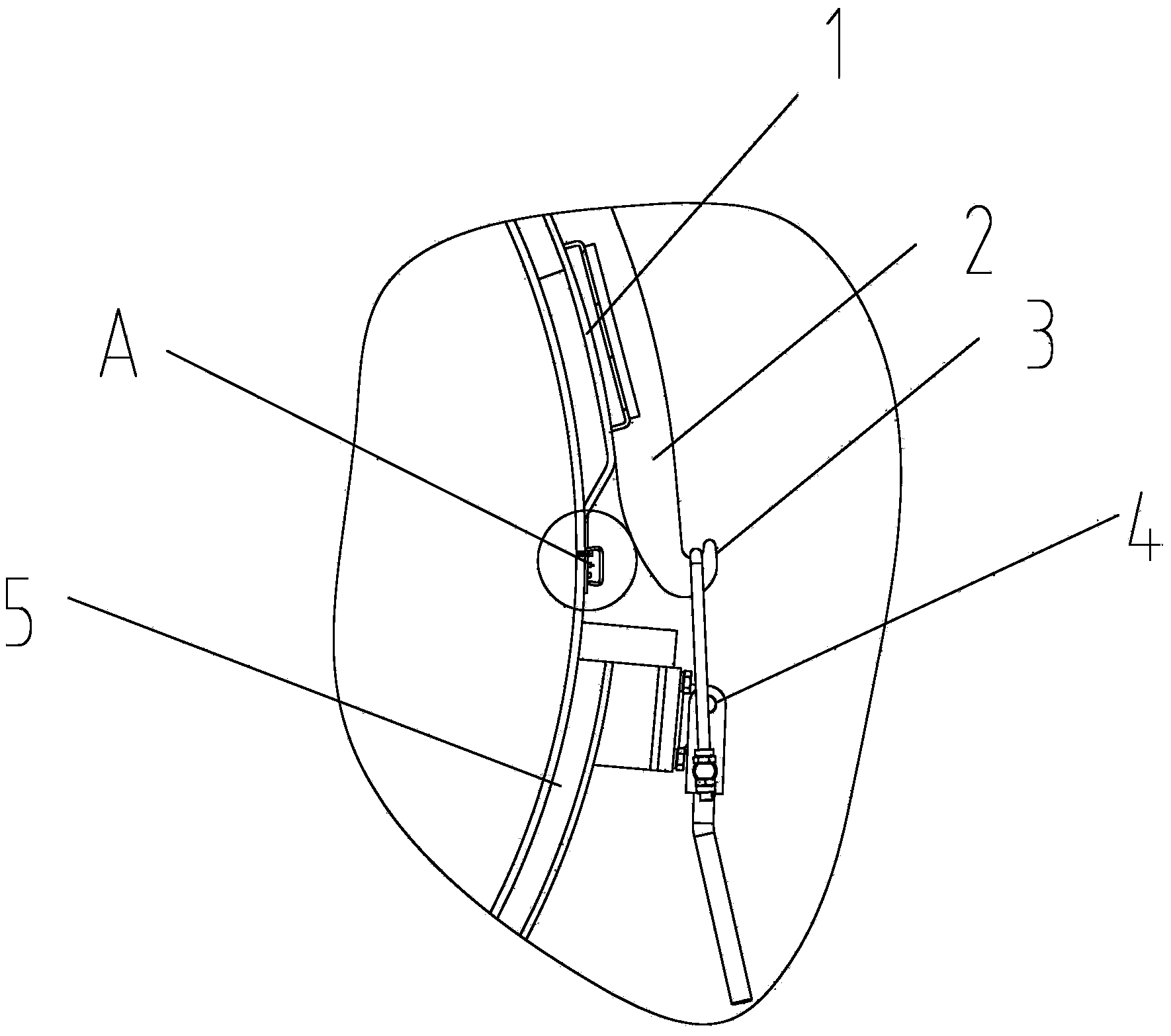

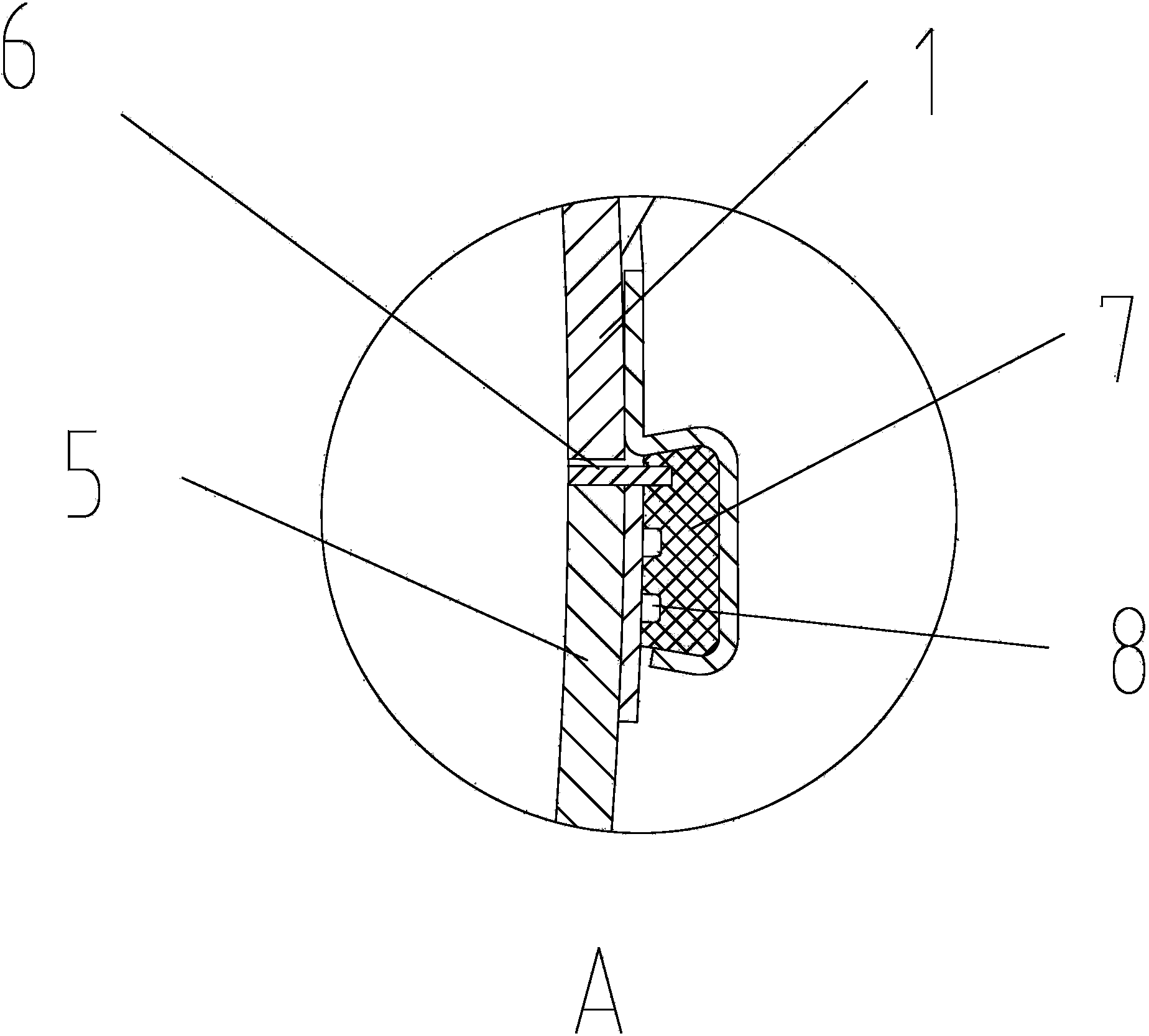

[0019] Such as Figure 1 ~ Figure 3 Shown: a sealing structure for the upper cover of the cooling mixer, including a cylindrical cylinder body 5 and a cylindrical upper cover 1 of the cooling mixer, the outer surface of the cylindrical body 5 is attached to the inner surface of the cylinder of the upper cover 1 , a sealing strip 7 is provided at the joint of the above two, and the sealing strip 7 has 2 to 3 rectangular grooves 8, and the cylinder body 5 is provided with an outer flange 6, and the outer flange 6 is in the cylinder The body 5 and the upper cover 1 are inserted into one of the rectangular grooves 8 when they are fitted together.

[0020] The present invention uses the cylindrical outer surface of the entire cylinder body 5 as the sealing surface, and the cylindrical inner surface of the upper cover 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com