Method for suspending speed tubular column of continuous oil tube

A velocity string and tubing technology, applied in the field of coiled tubing velocity string suspension, can solve problems such as unfavorable well site maintenance and layout, increased maintenance costs, increased supporting requirements, etc., to achieve standardized management and avoid supporting equipment and maintenance costs, the effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The core of the present invention is to provide a coiled tubing velocity string suspension method, which does not need to change the original production well pattern, thereby reducing the workload and construction cost.

[0046] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

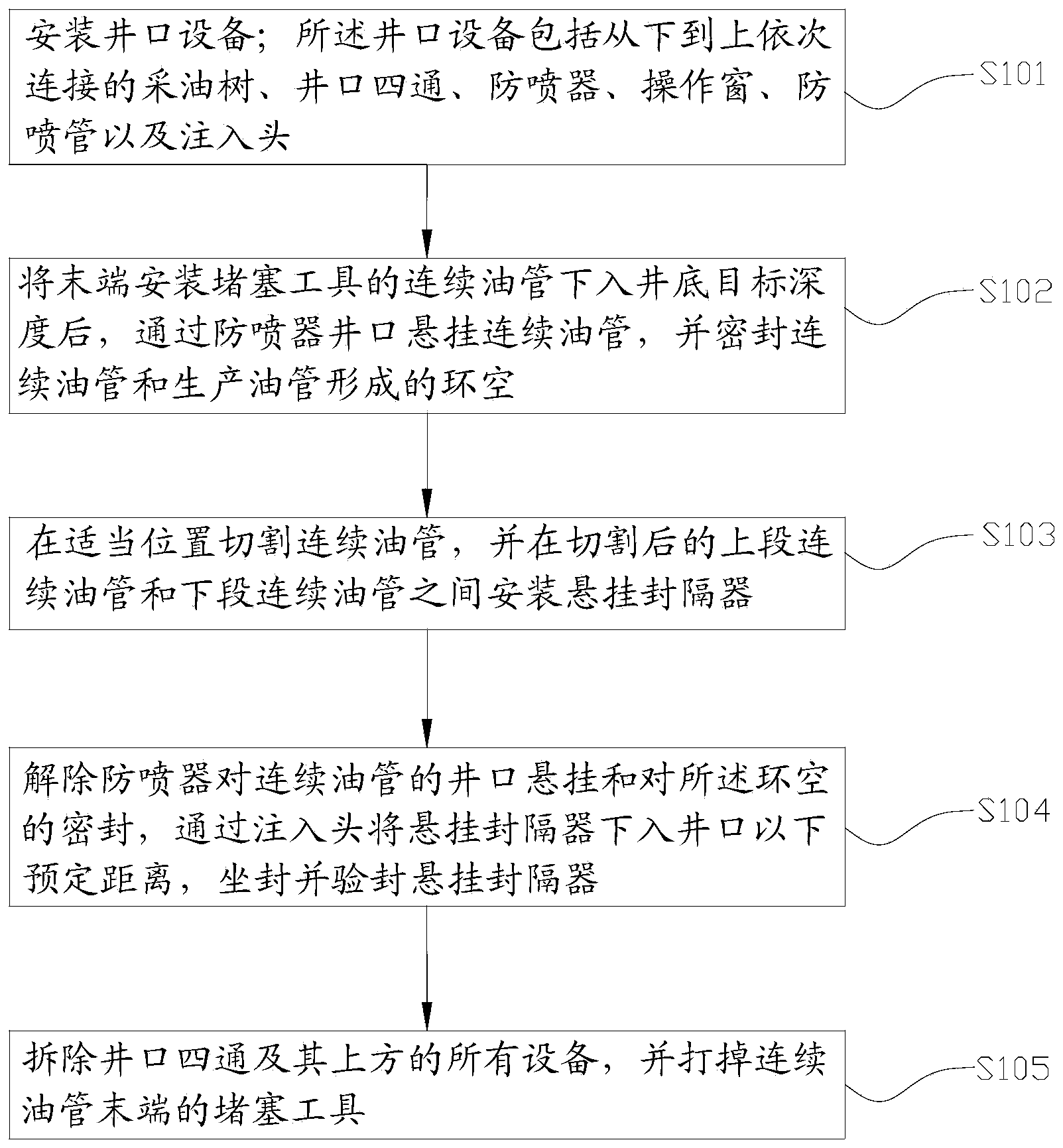

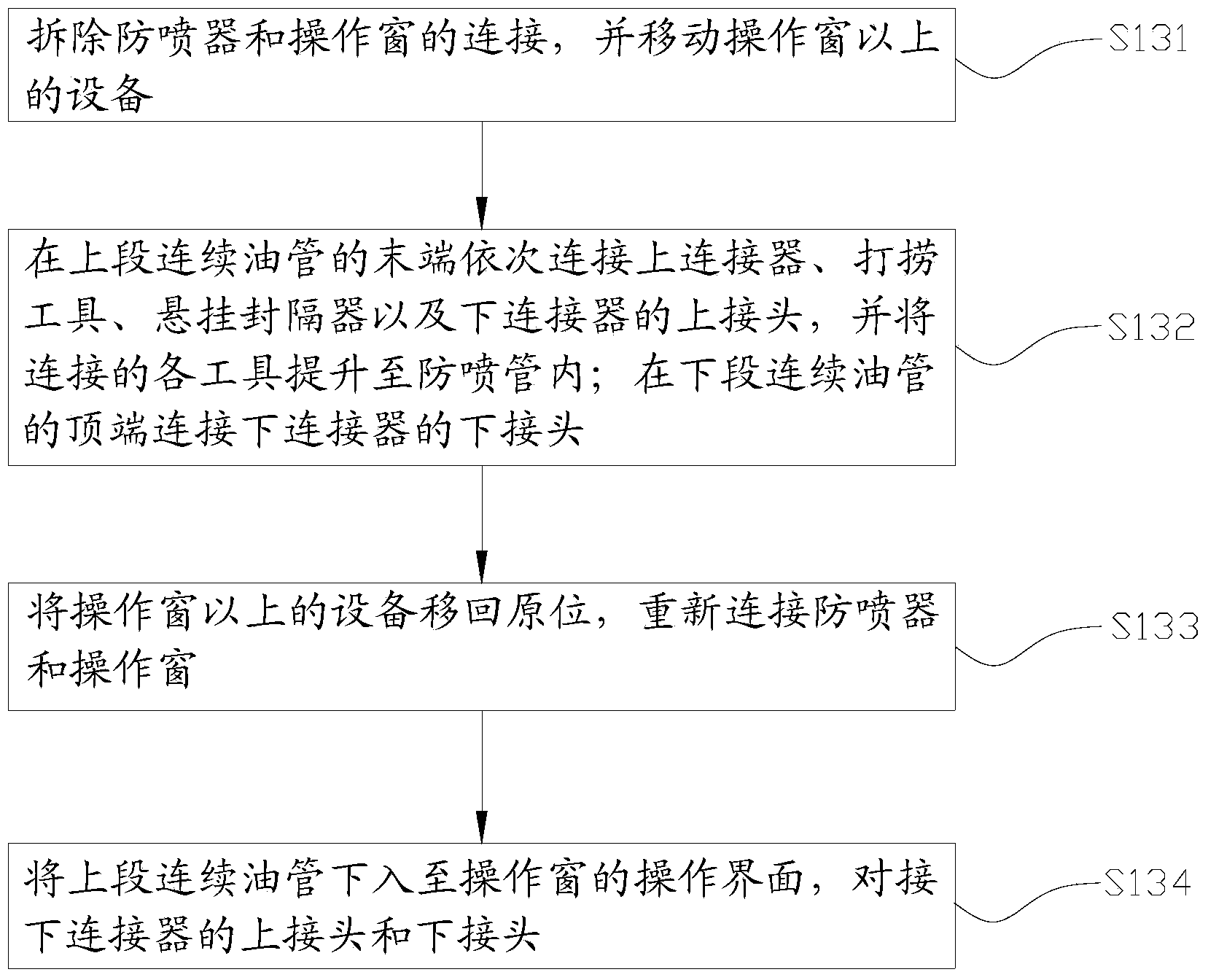

[0047] Please refer to figure 1 , figure 1 It is a schematic flowchart of a specific embodiment of the suspension method of the coiled tubing velocity string provided by the present invention.

[0048] In this embodiment, the coiled tubing velocity string suspension method provided by the present invention comprises the following steps:

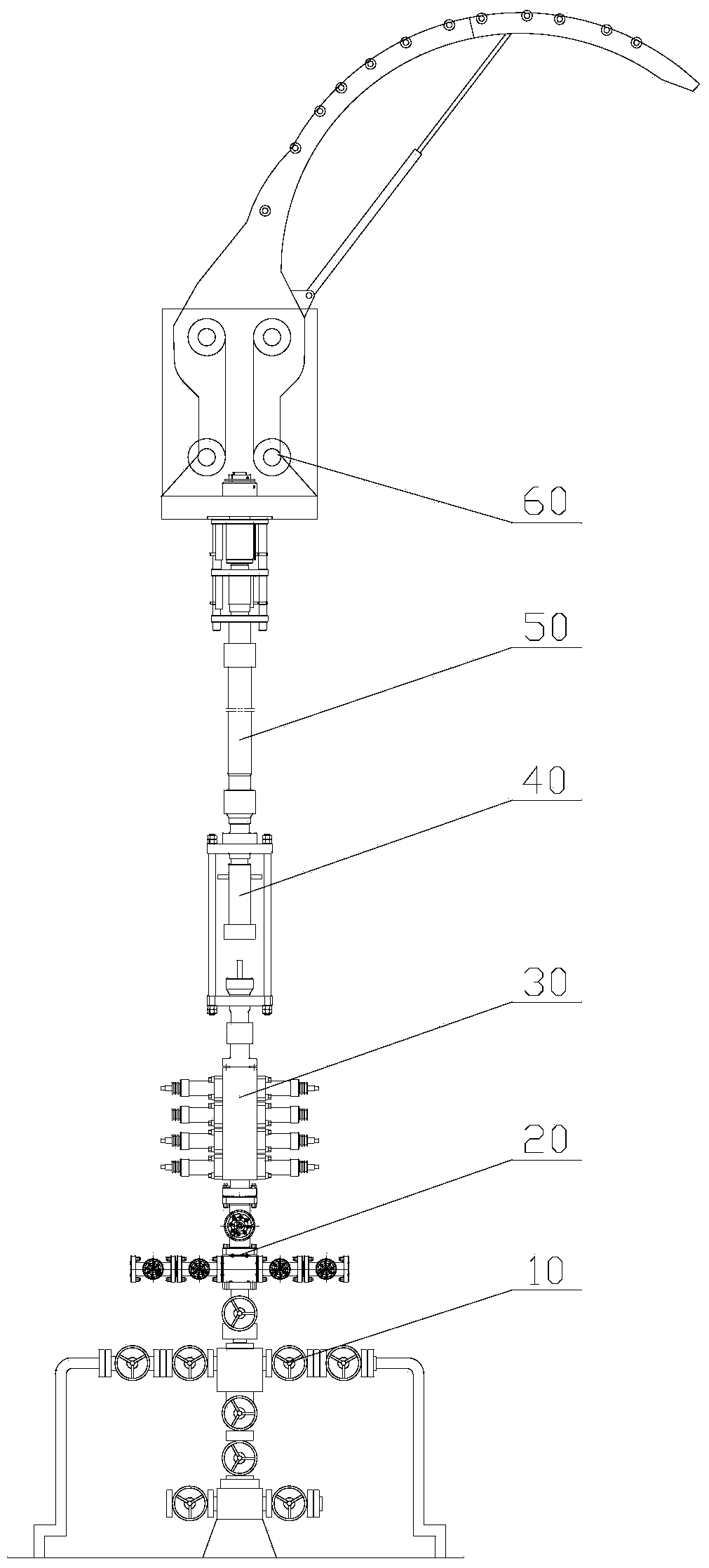

[0049] S101. Install wellhead equipment; the wellhead equipment includes a Christmas tree 10, a wellhead spool 20, a blowout preventer 30, an operation window 40, a blowo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com