Preparation method of ultrasmall NaYF4:Yb<3+>,Er<3+> upconversion luminescent material

A technology of luminescent materials and nanoparticles, which is applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of large size of luminescent materials, and achieve the effect of small size, no impurity phase, and high luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Dissolve 1.0mmol rare earth acetate in 6ml OA and 15ml ODE, Y:Yb:Er=78:20:2 in the rare earth acetate, heat to 100~130℃ and stir for 30~40min to form a uniform (2) When the temperature drops to 50-60°C, the NH dissolved in methanol 4 F was added to the solution together with NaOH and stirred for 30-40min, in which NH 4 F and NaOH are 4mmol and 2.5mmol respectively; (3) After removing methanol, the temperature of the solution is raised to 300°C for 90min, and then cooled to room temperature to obtain NaYF 4 :Yb 3+ ,Er 3+ Up-converting nanoparticles; (4) Washing the prepared up-converting nanoparticles with ethanol three times and then dispersing them in n-hexane.

[0025] The sample is a pure hexagonal phase structure with a size of about 24.6nm, such as figure 1 shown.

Embodiment 2

[0027] (1) Dissolve 0.5mmol rare earth acetate in 6ml OA and 15ml ODE, Y:Yb:Er=78:20:2 in the rare earth acetate, heat to 100~130℃ and stir for 30~40min to form a uniform (2) When the temperature drops to 50-60°C, the NH dissolved in methanol 4 F was added to the solution together with NaOH and stirred for 30-40min, in which NH 4 F and NaOH are 2mmol and 1.25mmol respectively; (3) After removing methanol, the temperature of the solution is raised to 300°C for 90min, and then cooled to room temperature to obtain NaYF 4 :Yb 3+ ,Er 3+ Up-converting nanoparticles; (4) Washing the prepared up-converting nanoparticles with ethanol three times and then dispersing them in n-hexane.

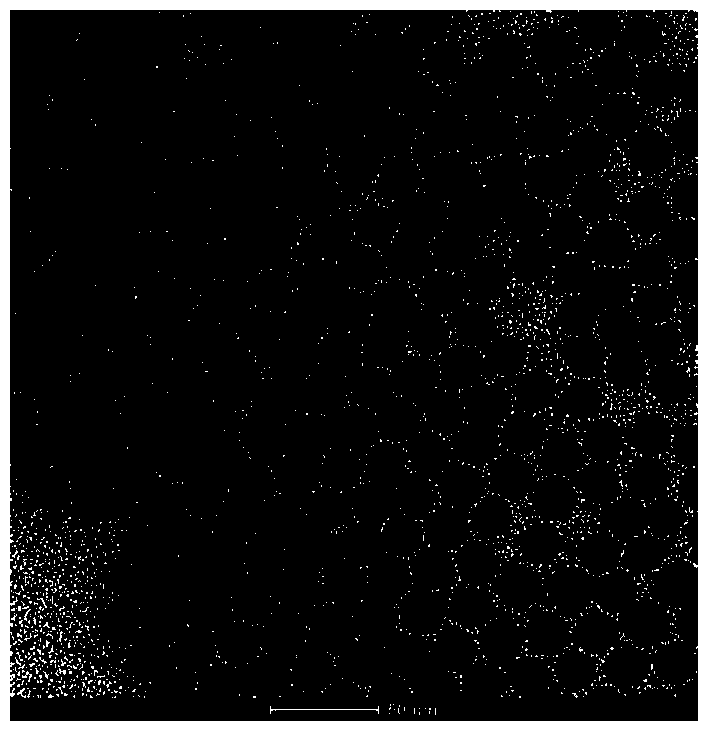

[0028] The sample is a pure hexagonal phase structure with a size of about 18.2nm, such as figure 2 shown.

Embodiment 3

[0030] (1) Dissolve 0.3mmol rare earth acetate in 30ml OA and 100ml ODE, Y:Yb:Er=78:20:2 in the rare earth acetate, heat to 100~130℃ and stir for 30~40min to form a uniform (2) When the temperature drops to 50-60°C, the NH dissolved in methanol 4 F was added to the solution together with NaOH and stirred for 30-40min, in which NH 4 F and NaOH are 1.2mmol and 0.75mmol respectively; (3) After removing methanol, raise the solution temperature to 300°C for 90min, then cool to room temperature to obtain NaYF 4 :Yb 3+ ,Er 3+ Up-converting nanoparticles; (4) Washing the prepared up-converting nanoparticles with ethanol three times and then dispersing them in n-hexane.

[0031] The sample is a pure hexagonal phase structure with a size of about 17.7nm, such as image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com