Sheet vacuum suction crane

A technology of suction crane and vacuum suction cup, which is applied to cranes, load hanging elements, walking bridge cranes, etc., can solve problems such as difficulty in lifting and handling, large production accidents, and increased failure rate, and reduce the burden of heavy lifting. labor, ensuring non-destructive handling, and saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

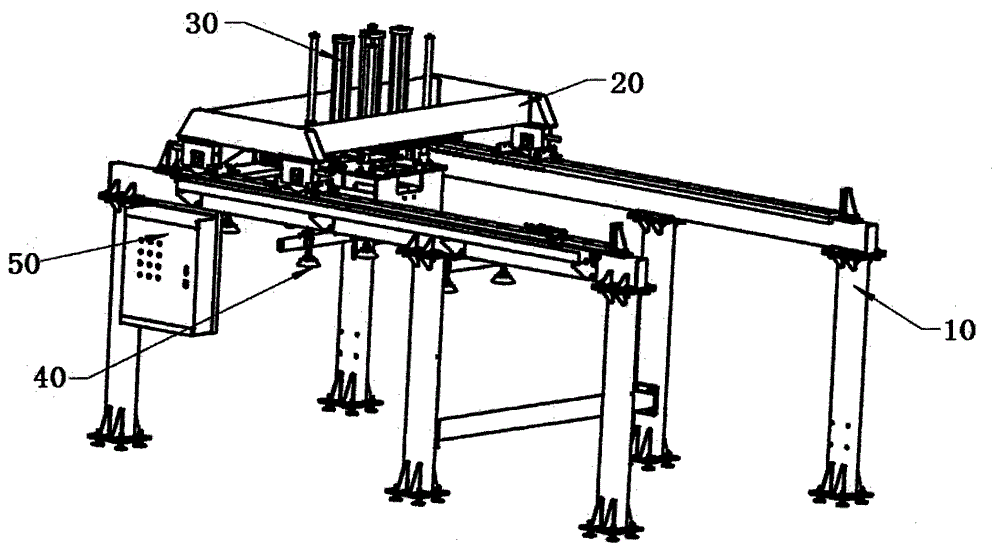

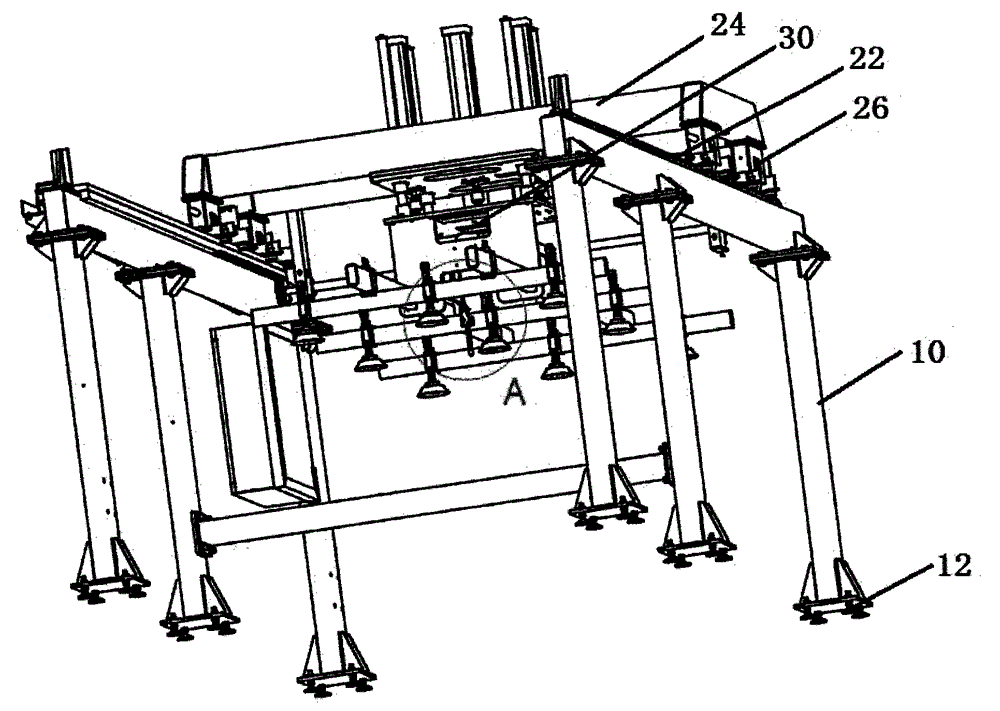

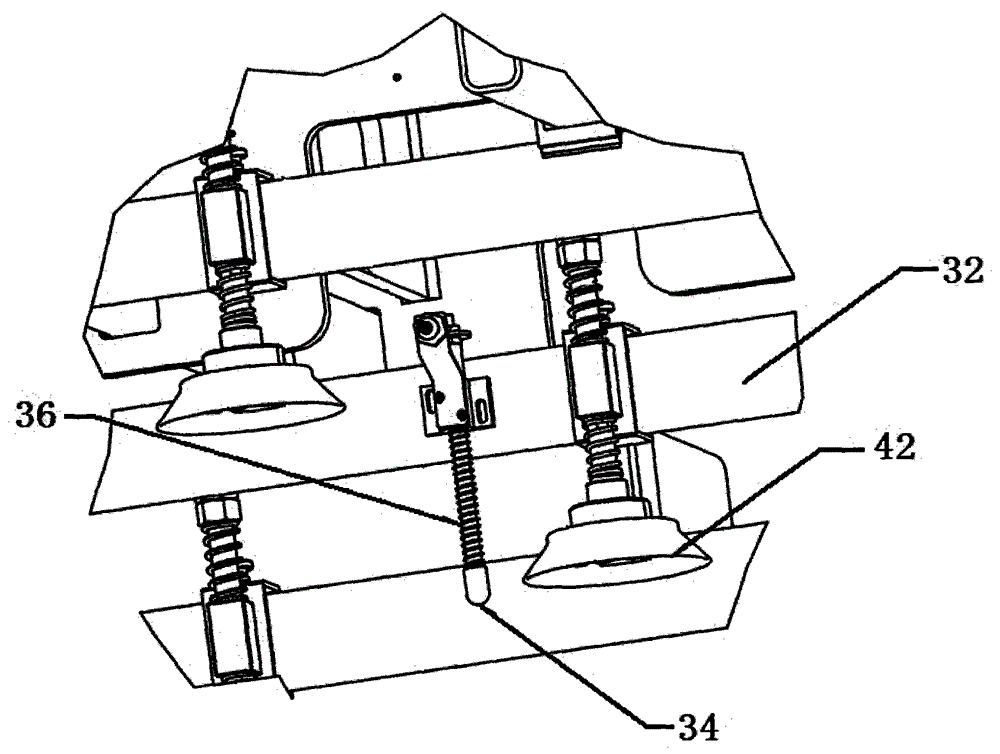

[0017] as attached Figure 1-3 As shown, the plate vacuum lifting machine described in this embodiment includes a frame 10, a traveling mechanism 20, a lifting mechanism 30, a vacuum suction cup set 40, and an electrical control device 50; the frame 10 is welded by section steel and is light in weight. , with large load and beautiful appearance, it is the basis for carrying materials and fixing the traveling device, with adjusting bolts 12 at the bottom for adjusting the level of the equipment during installation; the traveling mechanism 20 includes a linear guide rail 22 and a moving head 24, the linear The guide rail 22 is horizontally arranged on the frame 10, and the moving head 24 can move linearly back and forth on the linear guide rail through the rack and pinion 26. As an example, the rack and pinion can be driven by a reduction motor Provide power; and the lifting mechanism 30 is arranged in the moving head 24 and can move up and down relative to the moving head. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com