Chute feeding device

A technology of feeding device and chute, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of uneven sand loading in the chute, easy damage to equipment, low screening efficiency, etc. High screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

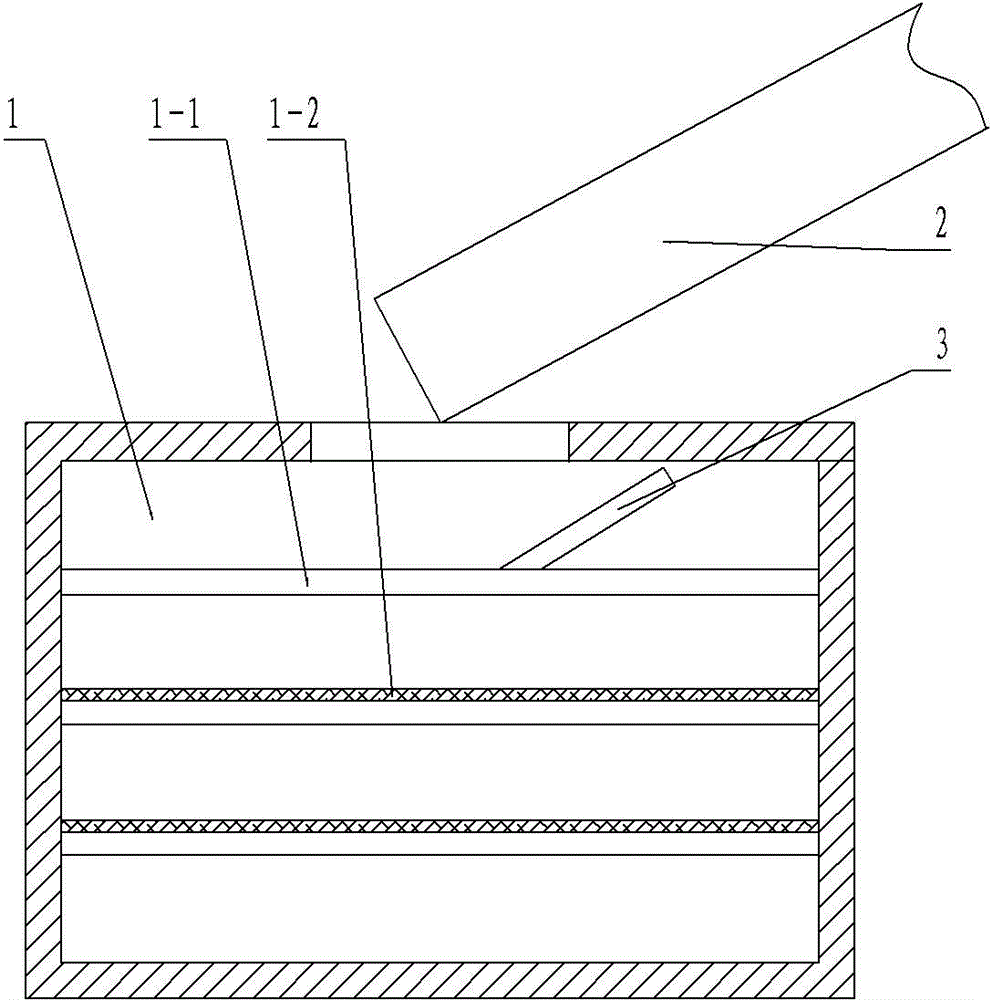

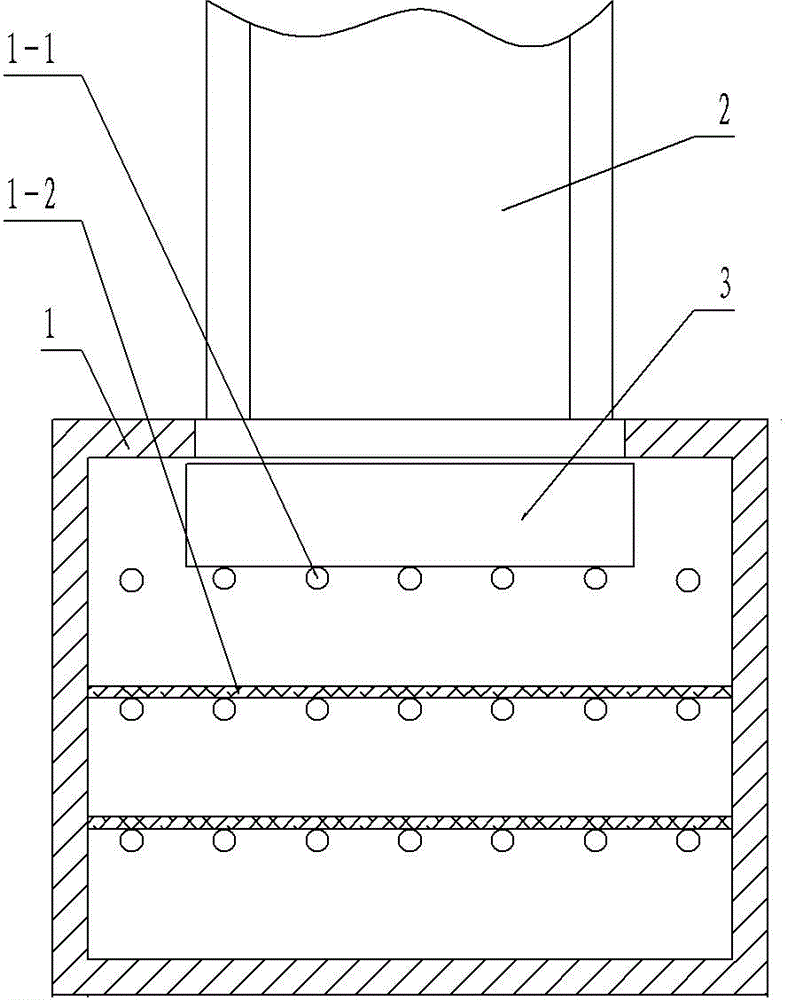

[0014] figure 1 , figure 2 The chute feeding device shown includes a chute 2 and an air screen 1, the chute 2 is arranged above the air sieve 1, and the upper part of the air sieve 1 is provided with a feeding port, and the feeding port and the outlet of the chute 2 have Corresponding to the feed port, there are multiple reinforcing rods 1-1 horizontally and horizontally arranged in the cavity of the air screen 1, and a filter screen 1-2 is arranged on the reinforcing rods, and the uppermost reinforcing rod corresponds to the discharge of the chute 2. The opening is inclined upwards to be provided with a material stopper 3, the angle between the material stopper 3 and the horizontal is 35°, the length of the material stopper 3 is 100cm, the width is 60cm, and the thickness is 2cm.

Embodiment 2

[0016] figure 1 , figure 2 The chute feeding device shown includes a chute 2 and an air screen 1, the chute 2 is arranged above the air sieve 1, and the upper part of the air sieve 1 is provided with a feeding port, and the feeding port and the outlet of the chute 2 have Corresponding to the feed port, there are multiple reinforcing rods 1-1 horizontally and horizontally arranged in the cavity of the air screen 1, and a filter screen 1-2 is arranged on the reinforcing rods, and the uppermost reinforcing rod corresponds to the discharge of the chute 2. Mouth is provided with baffle plate 3 obliquely upwards, and the angle between baffle plate 3 and horizontal plane is 46 °, and material baffle plate 3 is long 150cm, and width is 75cm, and height is 3cm.

[0017] In the present invention, the original reinforcing bar of the air screen is equipped with a material blocking plate, which breaks down the sand flow input from the chute to the air screen, and the sand flow is even an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com