A kind of low-grade oxygen-sulfur mixed lead-zinc ore polymetal recovery method

A lead-zinc ore, low-grade technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve problems such as increased consumption of sulfuric acid, high cost of flotation reagents, difficult to control the quality of zinc oxide products, etc., to achieve Improve the recovery rate and eliminate the effect of metal tailing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The raw ore contains 13.5% zinc, 0.9% lead, 5% iron, and an oxidation rate of 70%.

[0057] The raw ore enters the No. 1 ball mill. After ball milling, the pulp concentration in the No. 1 ball mill is 35-38, and the fineness is >75%. Then enter the spiral separator, the particle size is -300 mesh, and the part enters the crushing recovery system, and the combination of modified amines and pentaxanthate is used as a collector to obtain zinc sulfide. At this time, the yield is 10%, and the concentrate Grade 48%.

[0058] 85-90% of the output of the pulp enters the cyclone separator for classification, the pulp of -200 mesh at the upper outlet accounts for 80%, enters the flotation system, and the rest enters the closed-circuit grinding system of the No. 2 ball mill.

[0059] The pulp from the upper outlet of the cyclone separator enters the first group of flotation system with a pulp concentration of 35%. Using lime slurry, sodium sulfide vulcanization, and the combined...

experiment example 1

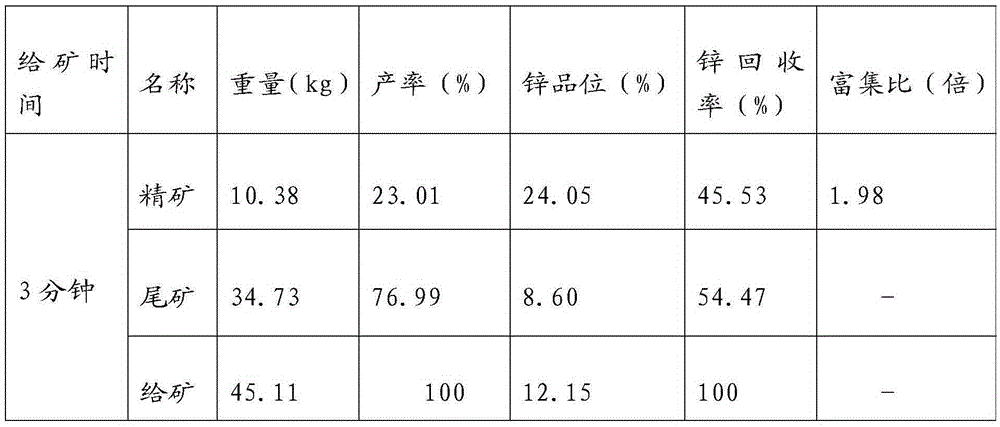

[0086] Experimental example 1: Industrial test average index (%)

[0087]

[0088] As can be seen from the above table, the industrial test can obtain lead concentrate containing 47.58% lead, lead recovery rate is 77.22%; zinc sulfide concentrate contains zinc 48.83%, zinc recovery rate is 37.05%; zinc oxide concentrate contains zinc 22.18%, zinc The recovery rate was 50.19%, and the solubility was 92.00%.

[0089] The industrial test results show that the beneficiation process of controlled dissociation two-stage graded grinding-enhanced fine sludge recovery-ladder flotation has obtained excellent beneficiation indicators. This process not only eliminates the influence of mud on lead and zinc recovery, but also effectively recovers Zinc oxide minerals in mud. The process is easy to control, and the beneficiation index is stable.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com