Fresh shrimp freezing method and fresh shrimp cryoprotective agent

A cryopreservation protection agent, fresh shrimp technology, applied in the processing field of aquatic products, can solve problems such as peculiar smell and affect the taste, and achieve the effects of reducing the loss of nutrients, prolonging the shelf life, and small changes in quality characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

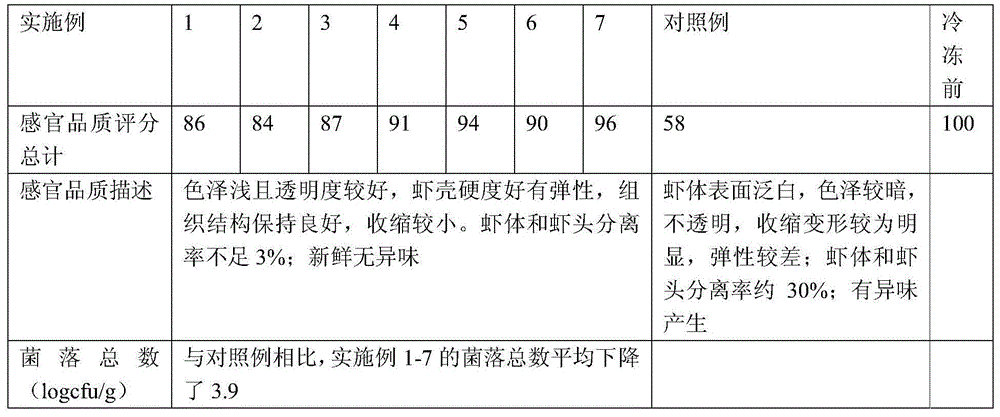

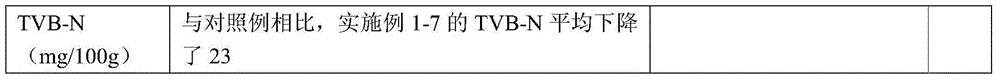

Examples

Embodiment 1-3

[0024] A kind of freezing method of fresh shrimp, concrete steps are as follows:

[0025] 1) Pretreatment of fresh shrimp: After draining the fresh shrimp, evenly spray cryoprotectant A on the surface of the fresh shrimp. The amount of cryoprotectant A is 15% of the weight of the fresh shrimp. The cryopreservation agent B is coated on the surface of the fresh shrimp, and the dosage of the cryopreservation agent B is 7% of the weight of the fresh shrimp, and it is allowed to stand for 10 minutes;

[0026] 2) Pre-freezing: Pre-freeze the pre-treated fresh shrimp at -20 to -25°C for 10 minutes;

[0027] 3) Packing: Take an appropriate amount of pre-frozen fresh shrimp and put it into a packaging bag, and vacuum seal the package;

[0028] 4) Quick-freezing: Place the product in a low-temperature environment with a temperature ≤-35°C for quick-freezing, and transfer it to a cold storage after freezing until the center temperature of the product is ≤-18°C.

[0029] The fresh shrim...

Embodiment 4

[0034] A kind of freezing method of fresh shrimp, concrete steps are as follows:

[0035] 1) Pretreatment of fresh shrimp: After draining the fresh shrimp, evenly spray cryoprotectant A on the surface of fresh shrimp. The dosage of cryoprotectant A is 12% of the weight of fresh shrimp. The cryopreservation agent B is coated on the surface of the fresh shrimp, and the dosage of the cryopreservation agent B is 4% of the weight of the fresh shrimp, and it is allowed to stand for 10 minutes;

[0036] 2) Pre-freezing: Pre-freeze the pre-treated fresh shrimp at -20 to -25°C for 20 minutes;

[0037] 3) Packing: Take an appropriate amount of pre-frozen fresh shrimp and put it into a packaging bag, and vacuum seal the package;

[0038] 4) Quick-freezing: Place the product in a low-temperature environment with a temperature ≤-35°C for quick-freezing, and transfer it to a cold storage after freezing until the center temperature of the product is ≤-18°C.

Embodiment 5

[0040] A kind of freezing method of fresh shrimp, concrete steps are as follows:

[0041] 1) Pretreatment of fresh shrimp: After draining the fresh shrimp, evenly spray cryoprotectant A on the surface of the fresh shrimp. The amount of cryoprotectant A is 5% of the weight of the fresh shrimp. The cryopreservation agent B is coated on the surface of the fresh shrimp, and the amount of the cryopreservation agent B is 7.5% of the weight of the fresh shrimp, and it is allowed to stand for 10 minutes;

[0042] 2) Pre-freezing: Pre-freeze the pre-treated fresh shrimp at -20 to -25°C for 10 minutes;

[0043] 3) Packing: Take an appropriate amount of pre-frozen fresh shrimp and put it into a packaging bag, and vacuum seal the package;

[0044] 4) Quick-freezing: Place the product in a low-temperature environment with a temperature ≤-35°C for quick-freezing, and transfer it to a cold storage after freezing until the center temperature of the product is ≤-18°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com