Backlight module, surface-mounted LED and packaging technology of surface-mounted LED

A technology of packaging technology and backlight module, which is applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of unfavorable cost reduction, product thickening, and increased cost of manual lens attachment, so as to reduce production costs, improve efficiency, The effect of omitting costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below with reference to the drawings and embodiments.

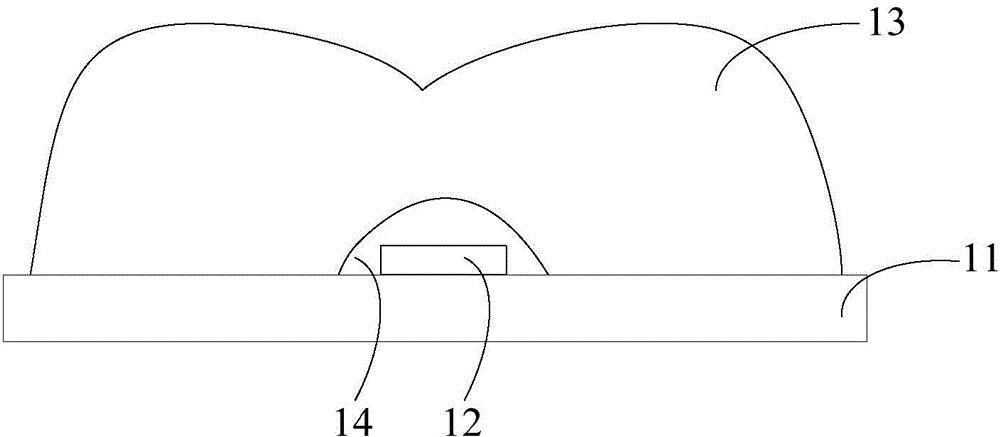

[0028] refer to figure 1 , In one embodiment of the SMD LED of the present invention, the SMD LED includes a bracket 11 and an LED chip 12 . Wherein, the bracket 11 is a flat bracket, and the LED chip 12 is fixed on the bracket 11 . A packaging lens 13 is also arranged on the bracket 11 . Preferably, the packaging lens 13 covers the LED chip 12 and is formed on the bracket 11 during the process of packaging the LED chip 12 on the bracket 11 . Of course, the encapsulation lens 13 may also be only partially disposed in the light emitting direction of the LED chip 12 .

[0029] Wherein, the process of packaging the LED chip 12 in the bracket 11 is to assemble the various components that make up the LED together to package to obtain a complete LED. In this embodiment, the packaging lens 13 is formed during the process of packaging the LED chip 12 on the bracket 11, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com