Furnace door tightly pressed through dead load and provided with adjustable idler wheel

An adjustable furnace door technology, used in furnaces, furnace components, lighting and heating equipment, etc., can solve the problems of inability to adjust the sealing pressure of the furnace door, cannot be used repeatedly, and the workload of repairing is large, and achieves simple and time-saving installation. The effect of convenient secondary maintenance and simple component configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the above-mentioned accompanying drawings.

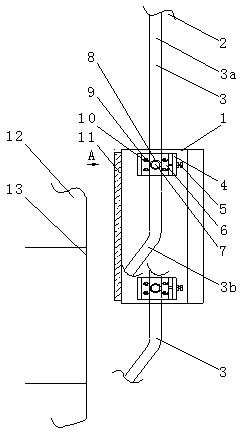

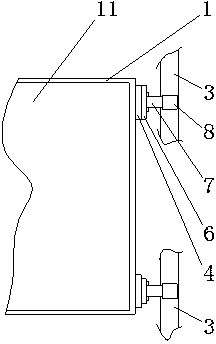

[0011] refer to figure 1 and figure 2 As shown, the adjustable roller of the heat treatment furnace of the present invention presses the furnace door by its own weight, including a furnace door body 1, a furnace door frame 2, a positioning plate 4, an adjusting plate 6, a support shaft 7 and a roller 8, and the furnace door body 1 is fixed with a furnace The door lining 11, the positioning plate 4 is equipped with an adjusting screw 5, and is fixed on the side of the furnace door body 1, and the adjusting plate 6 is provided with a long waist-shaped through-hole adjusting hole 10 for adjusting its installation position, and is fixed with a support shaft 7 , Roller 8 is housed on the fulcrum 7, penetrates the adjusting hole 10 of adjusting plate 6 by fixing screw 9, and adjusting plate 6 is fixedly installed on the positioning plate 4, and adjusting pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com