Double flow silk floss washing machine

A dual-flow, washing machine technology, applied in the direction of textiles and papermaking, fiber treatment, fiber chemical post-treatment, etc., can solve the problems of labor-consuming and time-consuming cooking, high labor intensity, silk floss degumming, and uneven oil removal, etc. Achieve the effect of improving the safe production environment, reducing labor intensity, and uniform degumming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

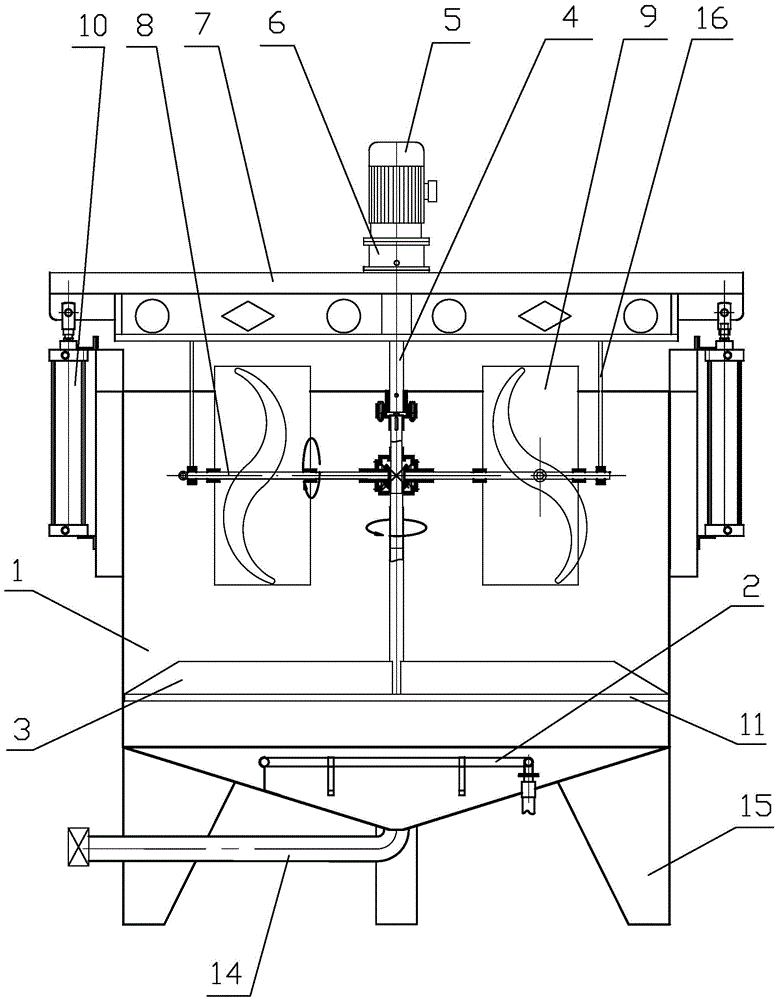

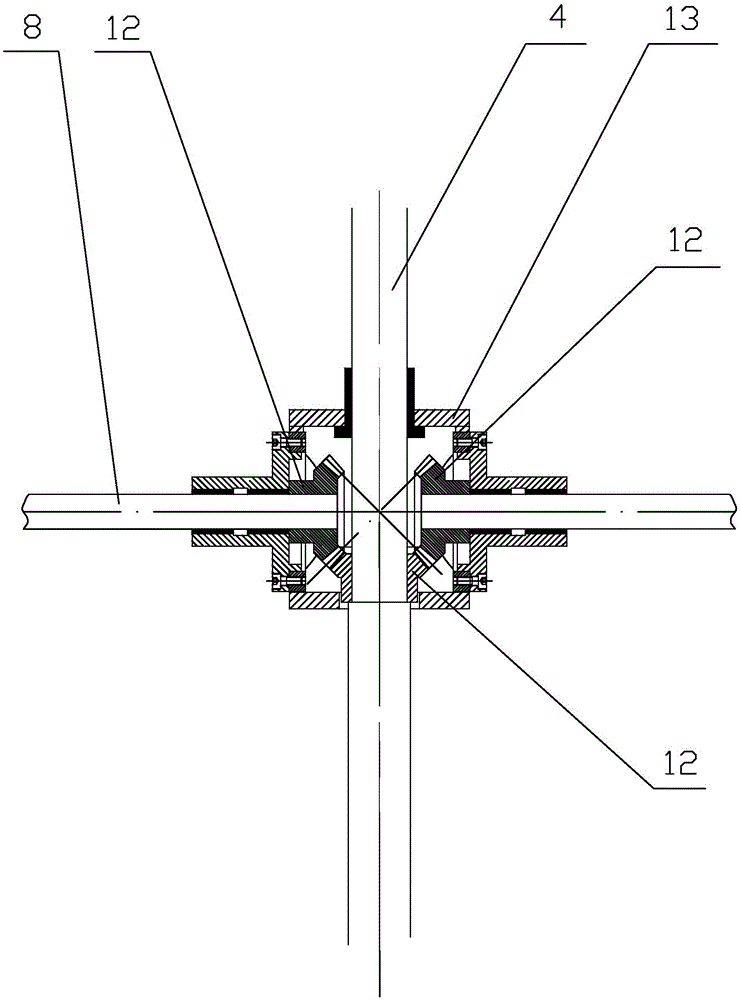

[0021] The dual-flow silk cotton washing machine of the present invention comprises a cotton boiling pot 1, a support 7, an agitator, a lifting mechanism, a bevel gear transmission mechanism, a motor 5, a reducer 6 and a heating device.

[0022] The cotton cooking pot 1 is supported by a tripod 15, and adopts a cylindrical pot body. The bottom of the pot body is conical, and the outlet at the bottom of the pot body is connected to the sewage pipe 14; The two ends are installed by the jacking gas-liquid cylinder 10 of the lifting mechanism, and the jacking gas-liquid cylinder 10 is installed vertically and symmetrically on the side wall of the pot body, and the top of the piston rod of the jacking gas-liquid cylinder 10 is supported on the two ends of the bracket 7 ,Such as figure 1 shown.

[0023] The heating device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com