Laser cladding method for preparing high-quality nickel-based alloy coating on titanium metal surface

A nickel-based alloy, laser cladding technology, applied in the field of surface modification, can solve the problems of large friction coefficient, poor wear resistance, low surface hardness of titanium metal, etc., to improve absorption performance, dense organization, and improve interface fusion performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Such as figure 1 -4 shown.

[0025] 98 grams of F101 nickel-based self-fluxing alloy powder (available directly on the market, the same below), lanthanum oxide (La 2 o 3 ) powder (can be purchased directly from the market, the same below), put it in a ball mill and mix evenly, take it out and dry it, and press it into a tablet on a press (thickness is about 0.7 mm, and the maximum compressible thickness is 1mm). Place the pressed sheet on the cleaned titanium surface, and use YLS-6000 fiber laser for laser cladding. The process parameters are: laser power 1.8KW, scanning speed 420mm / min, spot diameter 2mm. That is to obtain a high-quality nickel-based alloy coating on the surface of titanium metal.

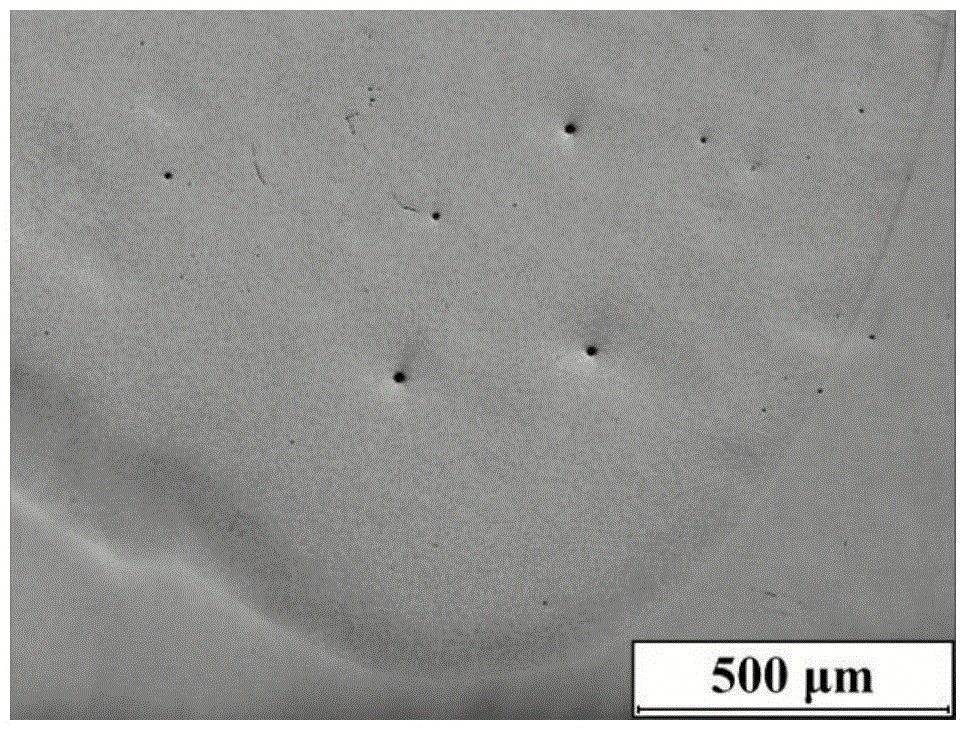

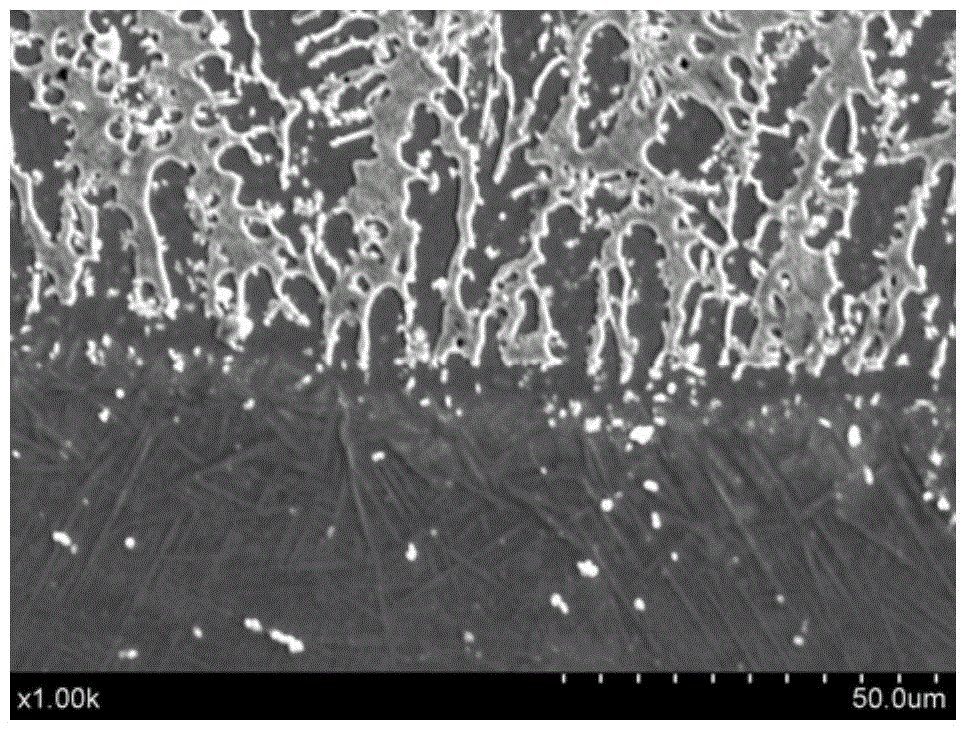

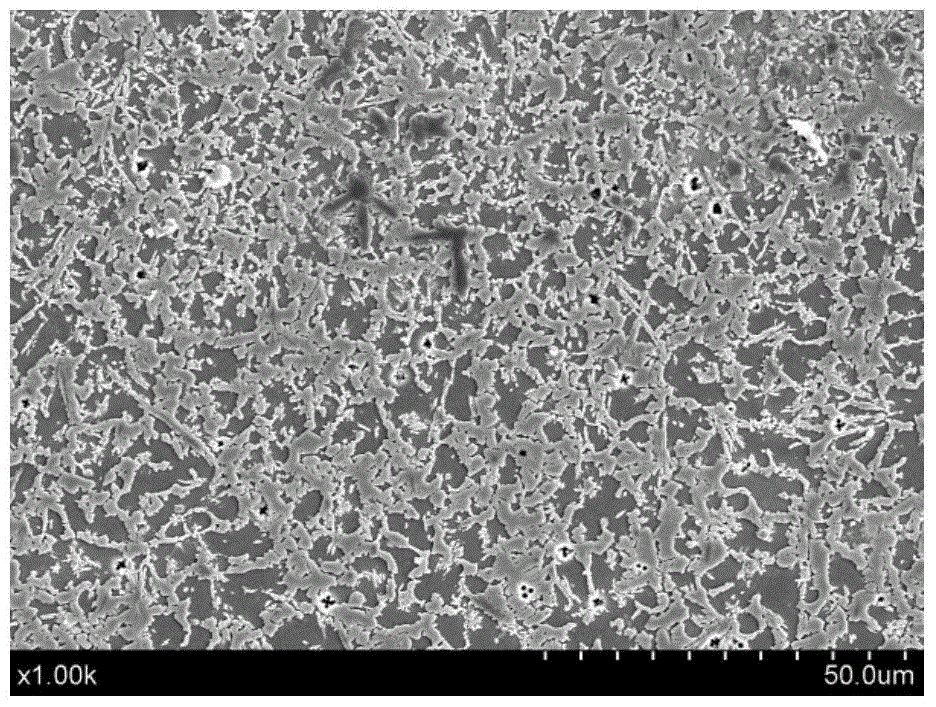

[0026] The coating structure that this embodiment obtains is compact ( figure 1 ), the interface is tightly combined ( figure 2 ), the coating structure is uniform and dense dendrites ( figure 2 , image 3 ), the hardness of the transition zone between the coatin...

Embodiment 2

[0028] 97 grams of F101 nickel-based self-fluxing alloy powder, lanthanum oxide (La 2 o 3 ) powder 3 grams, put it in a ball mill and mix evenly, take it out and dry it, and press it into a tablet (thickness is about 0.7 mm, and the maximum compressible thickness is 1 mm). Place the pressed tablet on the cleaned titanium surface, and use YLS-6000 fiber laser is used for laser cladding, the process parameters are: laser power 1.8KW, scanning speed 420mm / min, spot diameter 2mm. That is to obtain a high-quality nickel-based alloy coating on the surface of titanium metal.

[0029] The coating structure that this embodiment obtains is compact (with figure 1 similar), the interface is tightly combined (with figure 2 Similar), its average hardness is HV644.

Embodiment 3

[0031] 99 grams of F101 nickel-based self-fluxing alloy powder, lanthanum oxide (La 2 o 3 ) powder 1 gram, put it in a ball mill and mix it evenly, take it out and dry it, and press it into a tablet (thickness is about 0.7 mm, and the maximum compressible thickness is 1 mm). Place the pressed tablet on the cleaned titanium surface, and use YLS-6000 fiber laser is used for laser cladding, the process parameters are: laser power 1.8KW, scanning speed 420mm / min, spot diameter 2mm. That is to obtain a high-quality nickel-based alloy coating on the surface of titanium metal.

[0032] The coating structure that this embodiment obtains is compact (with figure 1 similar), the interface is tightly combined (with figure 2 Similar), its average hardness is HV640.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com