Low-cost antistatic polycarbonate resin and its preparation method

A polycarbonate resin, antistatic technology, applied in the field of communication and home appliances, can solve the problems of high price, avoid the loss of physical properties and reduce the cost of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

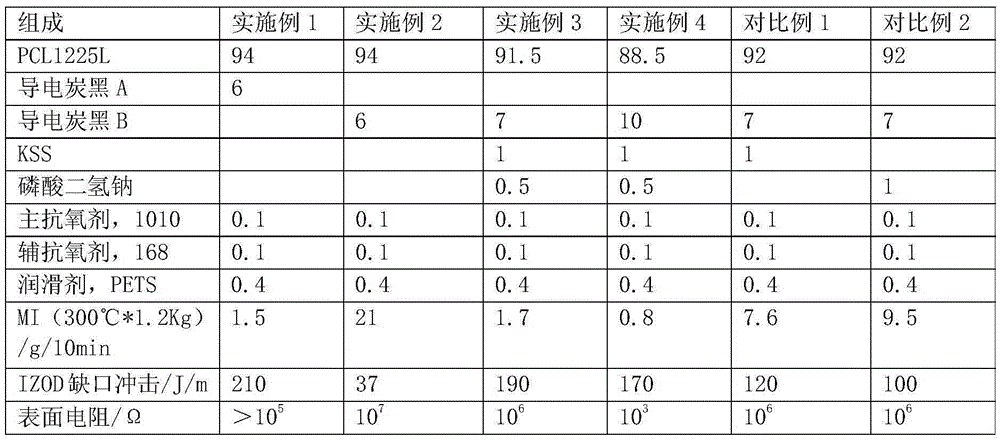

Examples

Embodiment 1

[0028] S11. Weigh 94 parts of PCL-1225L, 6 parts of conductive carbon black, 10100.1 parts of primary antioxidant, 1680.1 parts of secondary antioxidant, and 0.4 parts of lubricant PETS according to the formula of Example 1 in Table 1 below;

[0029] S12, mixing the base material weighed in the step S11 in a medium-speed mixer for 20 minutes;

[0030] S13. Put the mixture obtained in step S12 into a twin-screw extruder, extrude through a twin-screw extruder with a melting temperature of 200-280° C., and granulate to obtain a finished product.

Embodiment 2

[0032] S21. Weigh 94 parts of PCL-1225L, 6 parts of conductive carbon black, 10100.1 parts of primary antioxidant, 1680.1 parts of auxiliary antioxidant, and 0.4 part of lubricant PETS according to the formula of Example 2 in Table 1 below;

[0033] S22, mixing the base material weighed in the step S21 in a medium-speed mixer for 20 minutes;

[0034] S23. Put the mixture obtained in step S22 into a twin-screw extruder, extrude through a twin-screw extruder with a melting temperature of 200-280° C., and granulate to obtain a finished product.

Embodiment 3

[0036] S31. Weigh 1.5 parts of PCL-1225L, 7 parts of conductive carbon black, 1 part of KSS, 0.5 parts of sodium dihydrogen phosphate, 10100.1 parts of primary antioxidant, 1680.1 parts of secondary antioxidant according to the formula of Example 3 in Table 1 below, 0.4 parts of lubricant PETS;

[0037] S32, mixing the base material weighed in the step S31 in a medium-speed mixer for 20 minutes;

[0038] S33. Put the mixture obtained in step S32 into a twin-screw extruder, extrude through a twin-screw extruder with a melting temperature of 200-280° C., and granulate to obtain a finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com