Fixed positioning device of front section part of aircraft product

A positioning device and a fixed technology, applied in aircraft assembly, aircraft parts, ground installations, etc., can solve the problems of large deformation, difficulty in ensuring the assembly accuracy of large-sized parts, gaps, etc., to achieve large working space, realize digital assembly and The effect of automatic hole making and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The open assembly positioning system for the front part of the aircraft product provided by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

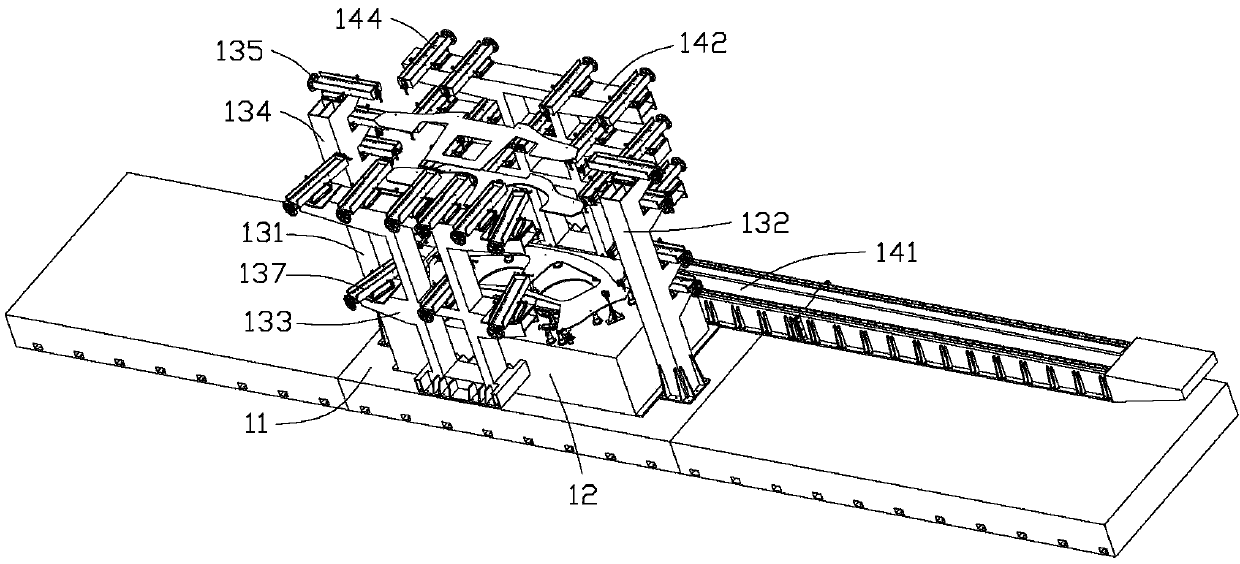

[0018] see figure 1 , the embodiment of the present invention provides an open assembly and positioning system for the front part of the aircraft product, which has the functions of assembling, positioning and fixing the frame of the front part of the aircraft product, so that each part of the aircraft product frame maintains an accurate relative position, and provides follow-up to the aircraft product. The strength, rigidity and spatial location required for the operation of the front-end components, for example, provide the operation space required for the automatic hole making of the subsequent CNC machine tool.

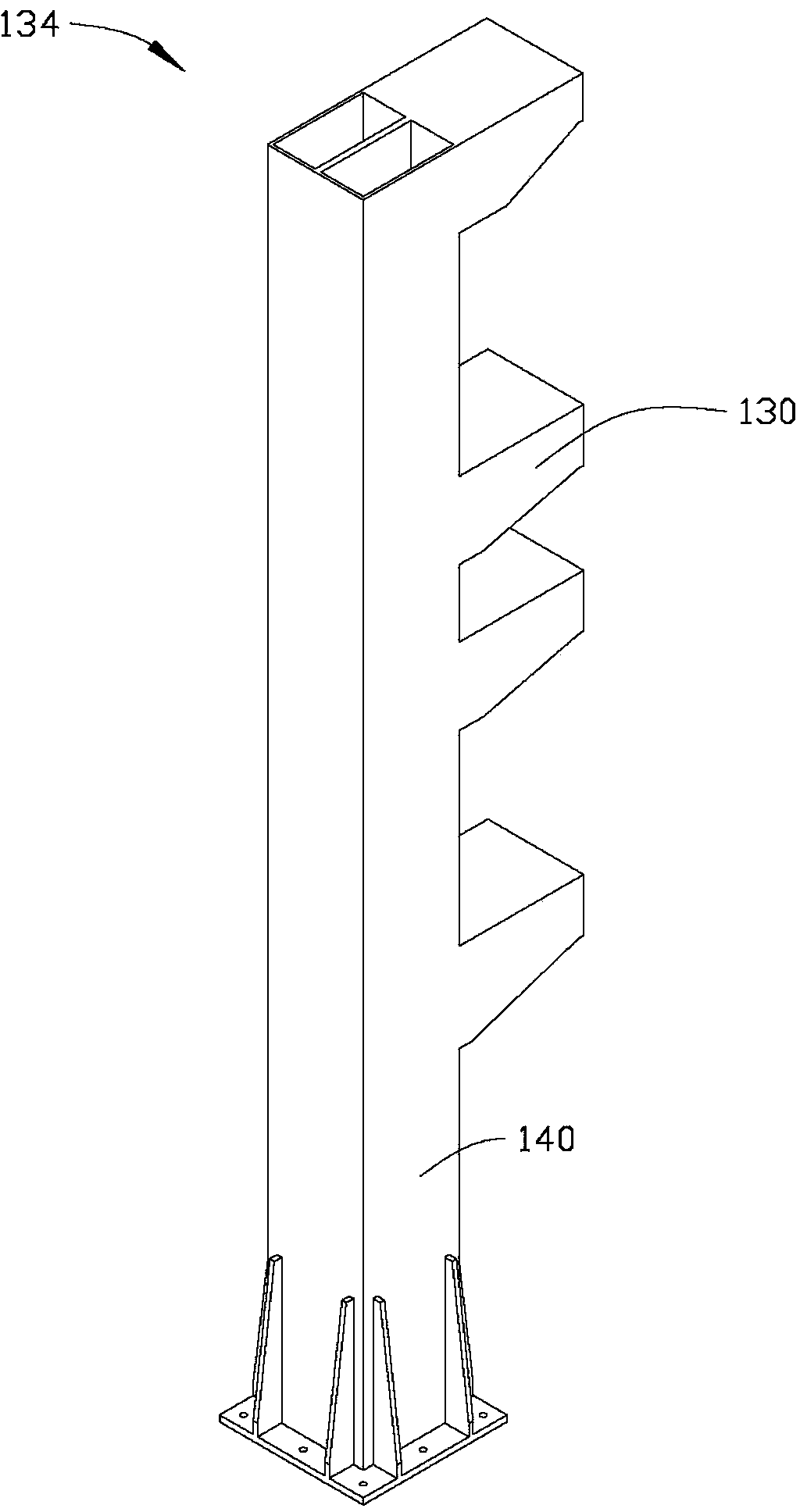

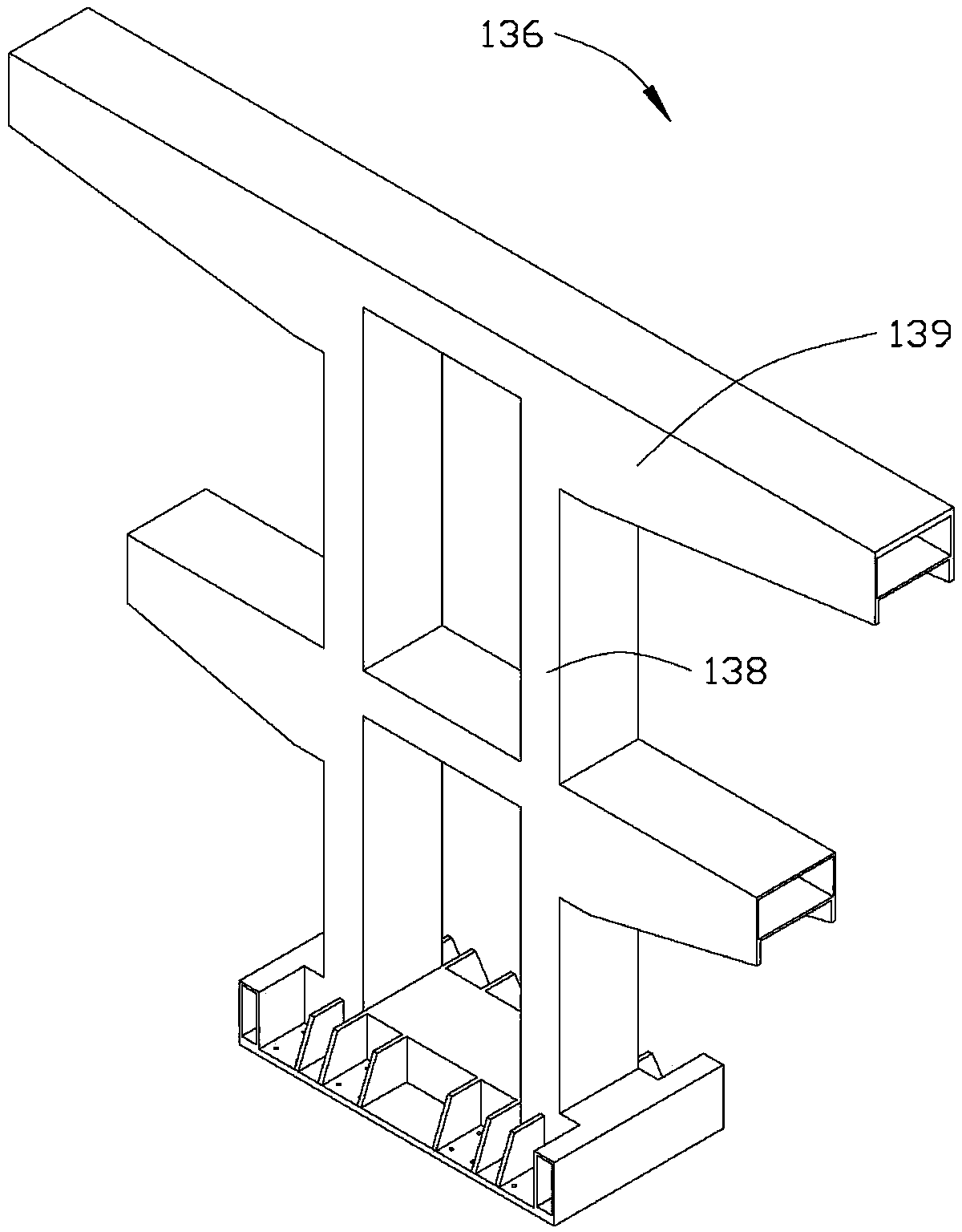

[0019] The open assembly and positioning system for the front part of the aircraft product includes a central workbench 11, a bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com