Steering wheel direction moving mechanism

A steering wheel and rotating disc technology, applied in steering mechanisms, steering mechanisms, steering mechanisms with deflectable wheels, etc., can solve problems such as chains that are easily rusted, easily broken or deformed, and the large rotational resistance of the steering wheel affects safe operation. The effect of low steering resistance and easy steering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

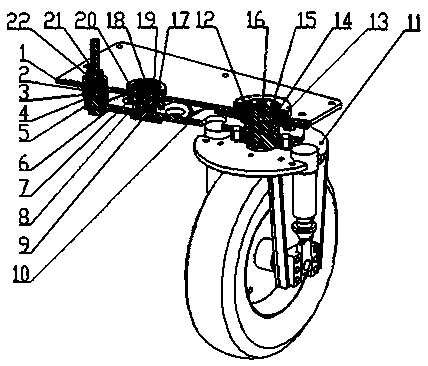

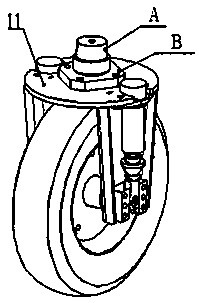

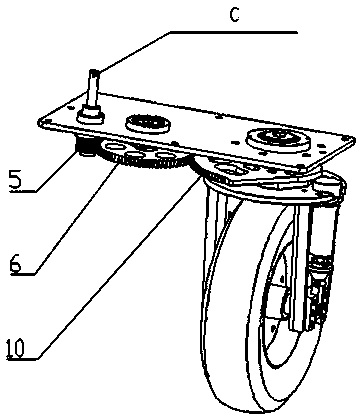

[0028] The invention discloses a steering wheel steering mechanism, which is driven by three gears engaged with each other; wherein the rotating disk gear is provided with sector-shaped external teeth;

[0029] The steering wheel steering mechanism relies on three gears to engage and drive to realize the direction offset steering, and the existing generally relies on the chain to drive the sprocket to realize the steering, that is, relying on the chain to drive the two sprockets to synchronously drive the same direction to achieve steering, However, the steering wheel steering mechanism of the present embodiment realizes the steering by means of three gears meshing and driving at first synchronously and in different directions, and then transitioning to synchronous and same-direction transmission. Since there is a transition gear in the middle, the offset distance transmission is realized from the input (removing the pinion) to the output (rotating disk), and the purpose of off...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com