Track type running mechanism and track vehicle

A traveling mechanism and crawler type technology, applied in crawler vehicles, motor vehicles, transportation and packaging, etc., can solve the problems of excessive turning resistance torque, increased cost, energy waste, etc., to reduce steering resistance, reduce contact length and area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

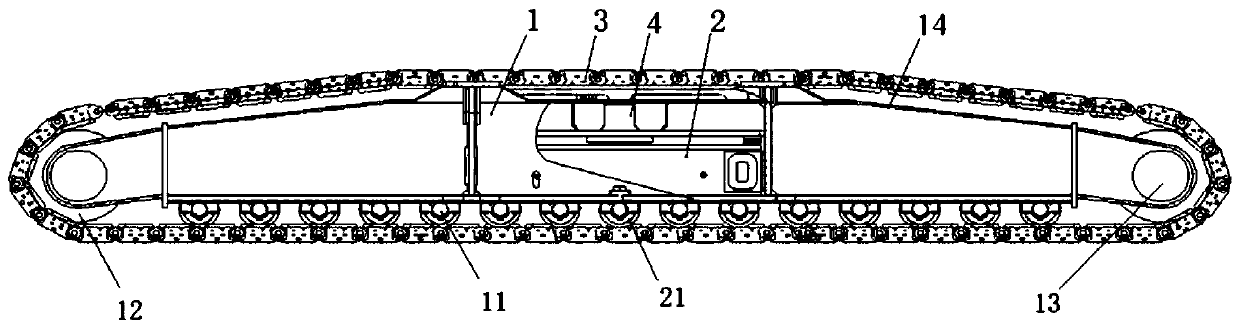

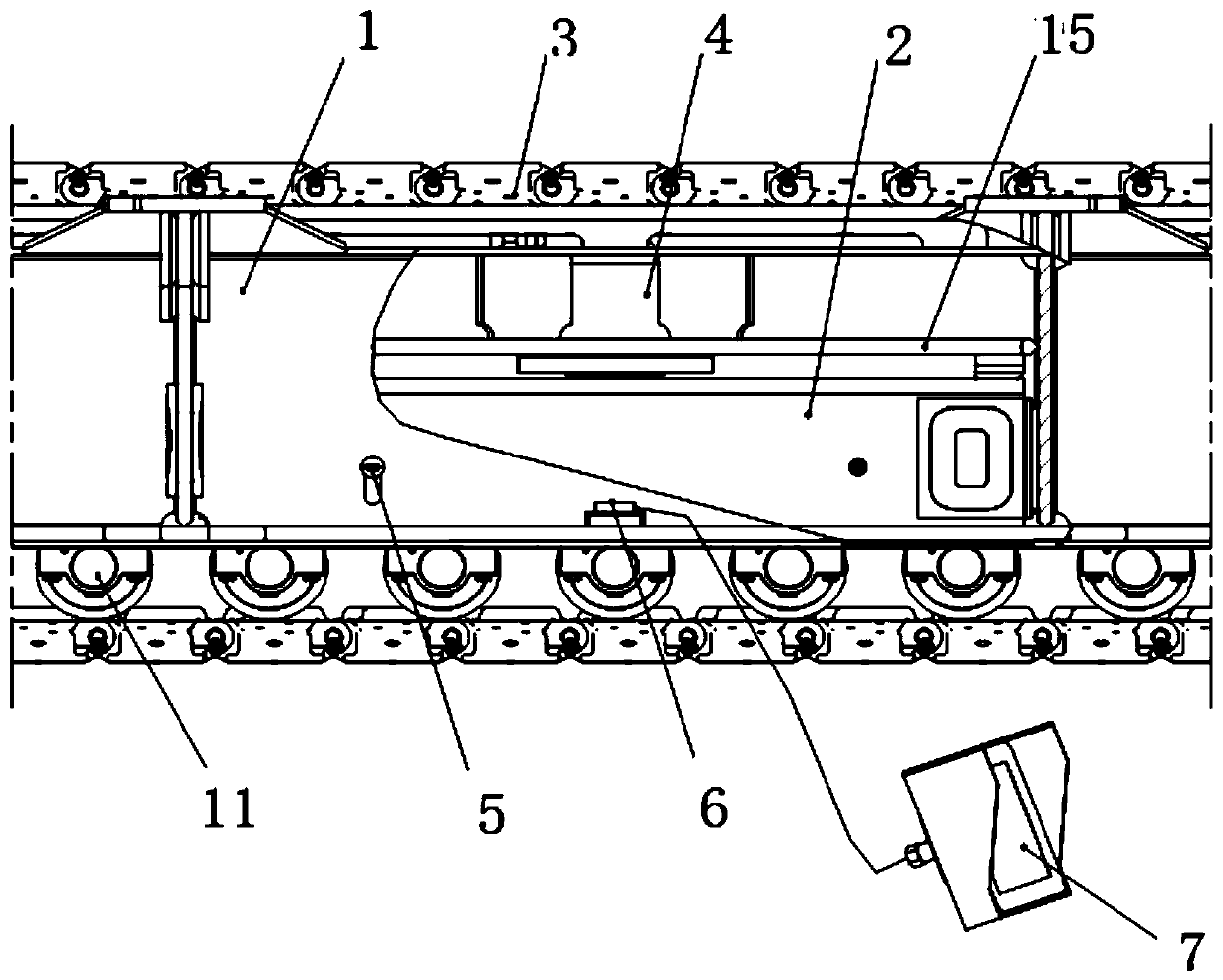

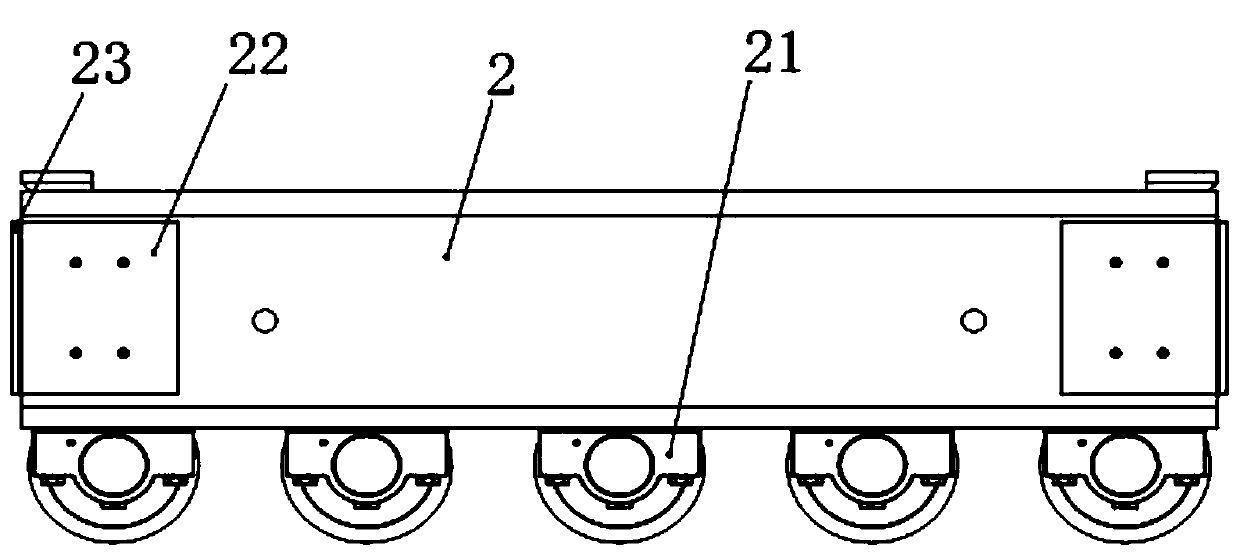

[0040] figure 1 Schematic diagram of the structure of the crawler-type traveling mechanism provided by the embodiment of the present invention, figure 2 It is a schematic diagram of the partial structure of the crawler-type traveling mechanism provided by the embodiment of the present invention, image 3 For the structural diagram of the inner box of the crawler-type traveling mechanism provided by the embodiment of the present invention, please refer to Figure 1-3 , this embodiment provides a crawler-type walking mechanism, including an outer box 1, an inner box 2 and a crawler belt 3, the inner box 2 is set inside the outer box 1, and the crawler belt 3 is set on the inside of the outer box 1 On the outer box 1;

[0041] The bottom of the outer box 1 is provided with a first roller 11, and the bottom of the inner box is provided with a second roller 21; the outer box 1 and the inner box 2 are provided with A driving structure 4, the driving structure 4 is used to drive ...

Embodiment 2

[0046] This embodiment has an overall structure similar to that of Embodiment 1, the difference is that this embodiment provides the installation position of the drive structure and the specific structures of the inner box and the outer box.

[0047] see Figure 1-3 , in this embodiment, the fixed end of the driving structure is arranged on the inner side of the top wall of the outer box 1, the crawler frame 14 of the outer box 1 is provided with a mounting plate 15, and the driving structure 4 is arranged on the mounting plate 15, the driving end of the driving structure is close to the outer side of the top wall of the inner box 2; the driving structure 4 is used to press down the top of the inner box 2 when the running mechanism turns. The wall makes the outer box body 1 lift upward relative to the inner box body under the action of the supporting reaction force of the driving structure. The driving structure 4 of this embodiment is an oil cylinder, and the oil cylinder is...

Embodiment 3

[0053] This embodiment provides a crawler-type traveling mechanism, which has an overall structure similar to that of Embodiment 1, except that this embodiment provides a crawler-type traveling mechanism with an intelligent steering function.

[0054] see Figure 1-3 , in this embodiment, the crawler-type traveling mechanism also includes a level detector 6 and a controller 7, the controller is connected to the drive structure, and the level detector 6 is used to detect the offset of the center of gravity of the crawler vehicle, The level detector 6 is also used to send the offset to the controller, and the controller 7 is used to control the driving structure action according to the offset;

[0055] The controller 7 is also used to control the drive structure to press down the top of the inner box 2 when the offset is greater than a first preset value, so that the outer box 1 is relatively The inner box body 2 is lifted upwards, and keeps the track under the second roller 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com