Combined heavy hydraulic truck

A combined, heavy-duty technology, applied in the field of transport vehicles, which can solve the problems of limited compensation and uneven loading of axles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The following descriptions are only preferred embodiments of the present invention, and do not limit the protection scope of the present invention. The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

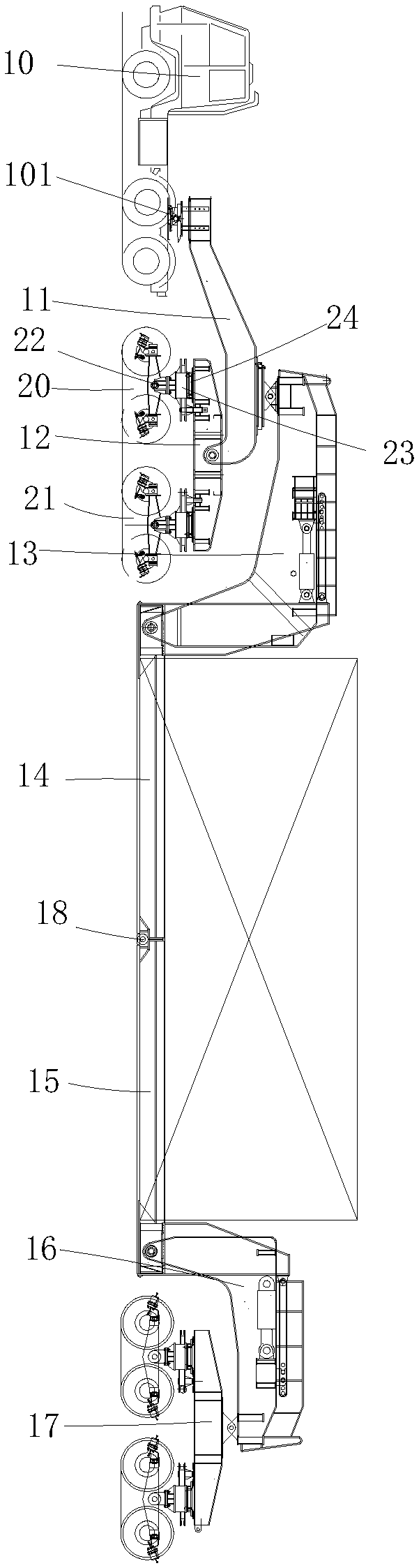

[0011] Examples, see figure 1 Shown: a combined heavy-duty hydraulic vehicle, which includes a tractor 10, a wolf truck main beam 11, a wolf truck platform 12, a front gooseneck 13, a front cargo platform 14, a rear cargo platform 15, a rear gooseneck 16 and a truck platform 17. One end of the wolf car main beam 11 is connected to the saddle 101 on the tractor 10, and the other end is hinged to the wolf car platform 12. This structure increases the longitudinal driving angle. On the wolf car platform 12, a front steering mechanism 20 and a rear steering mechanism 21 are arranged. Steering mechanism 21 is all made of single-point suspension 22, suspension column 23, turntable 24 and steering oil cylinder, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com