A special equipment semi-trailer chassis

A special equipment and semi-trailer technology, applied in the direction of motor vehicles, vehicle parts, pedals or ladders, etc., can solve the problems of reduced driving safety, inability to pass through cables, poor stability, etc., and achieve low load-bearing center of gravity. The effect of ingenious design and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the scope of protection is not limited to the content described in this embodiment.

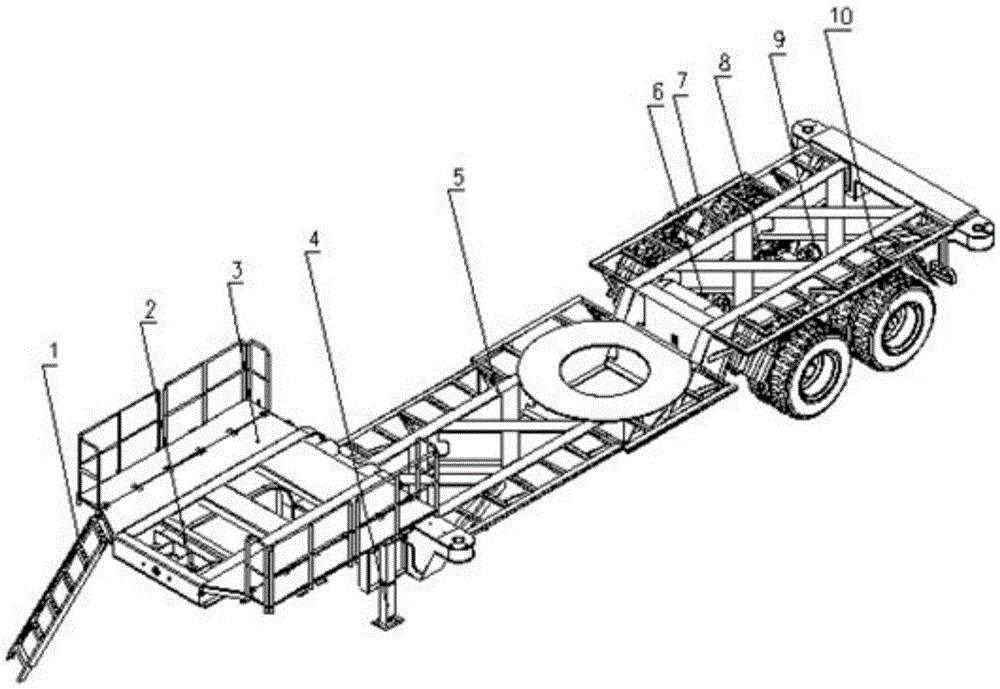

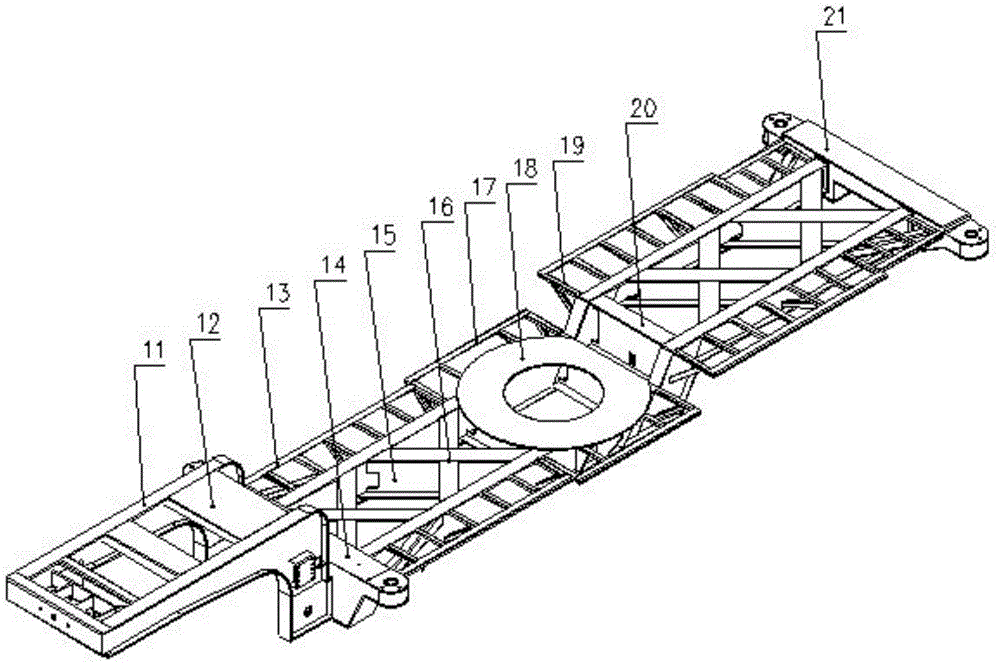

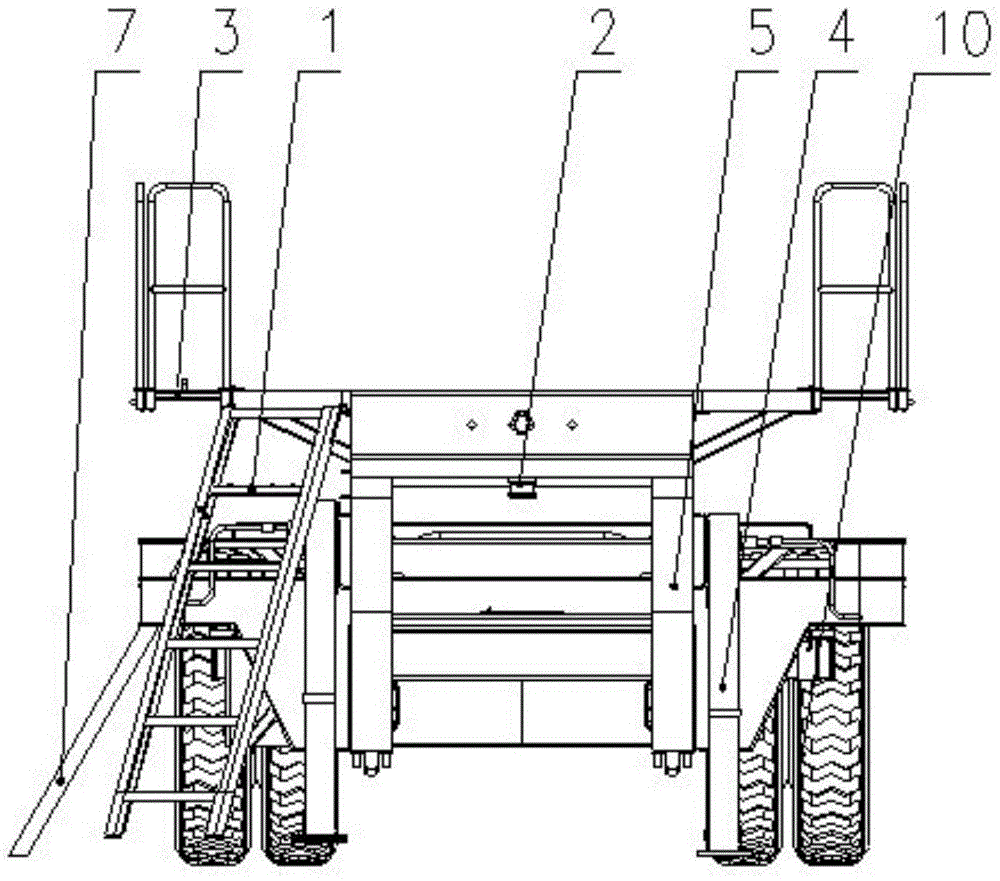

[0026] Such as Figure 1~5 As shown, the present invention is a semi-trailer chassis for special equipment, including traction pin 2, mechanical outrigger 4, vehicle frame 5, electrical system 6, suspension system 8, air brake system 9, wheel axle system 10, traction pin 2 It is connected and fixed in the middle of the front of the vehicle frame 5, the electrical system 6 is shuttled and connected under the vehicle frame 5, the suspension system 8 is connected and fixed above the wheel axle at the rear end of the vehicle frame 5, and the wheel axle system 10 is connected and fixed under the wheel frame at the rear end of the vehicle frame .

[0027] It also includes a maintenance ladder 1, a maintenance platform 3, and a pedal ladder 7. The maintenance ladd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com