Molding apparatus

A molding device and molding material technology, which is applied in the field of pre-melted polyamide molding devices and insert molding, can solve the problems of unusable potting, a large amount of waste, long curing time, etc., and achieve low operating costs, reduced production cycle, large The effect of machine throughput

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

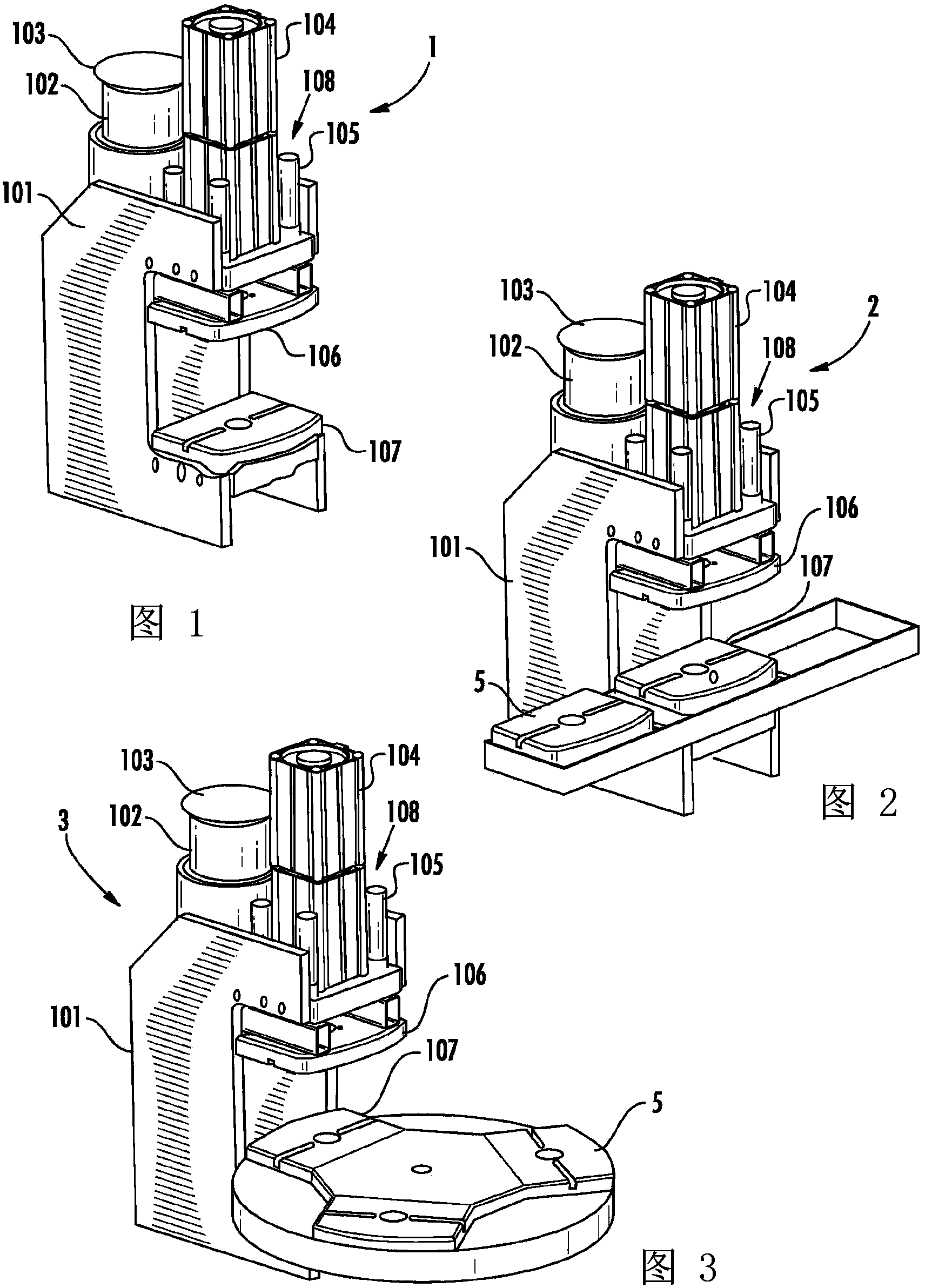

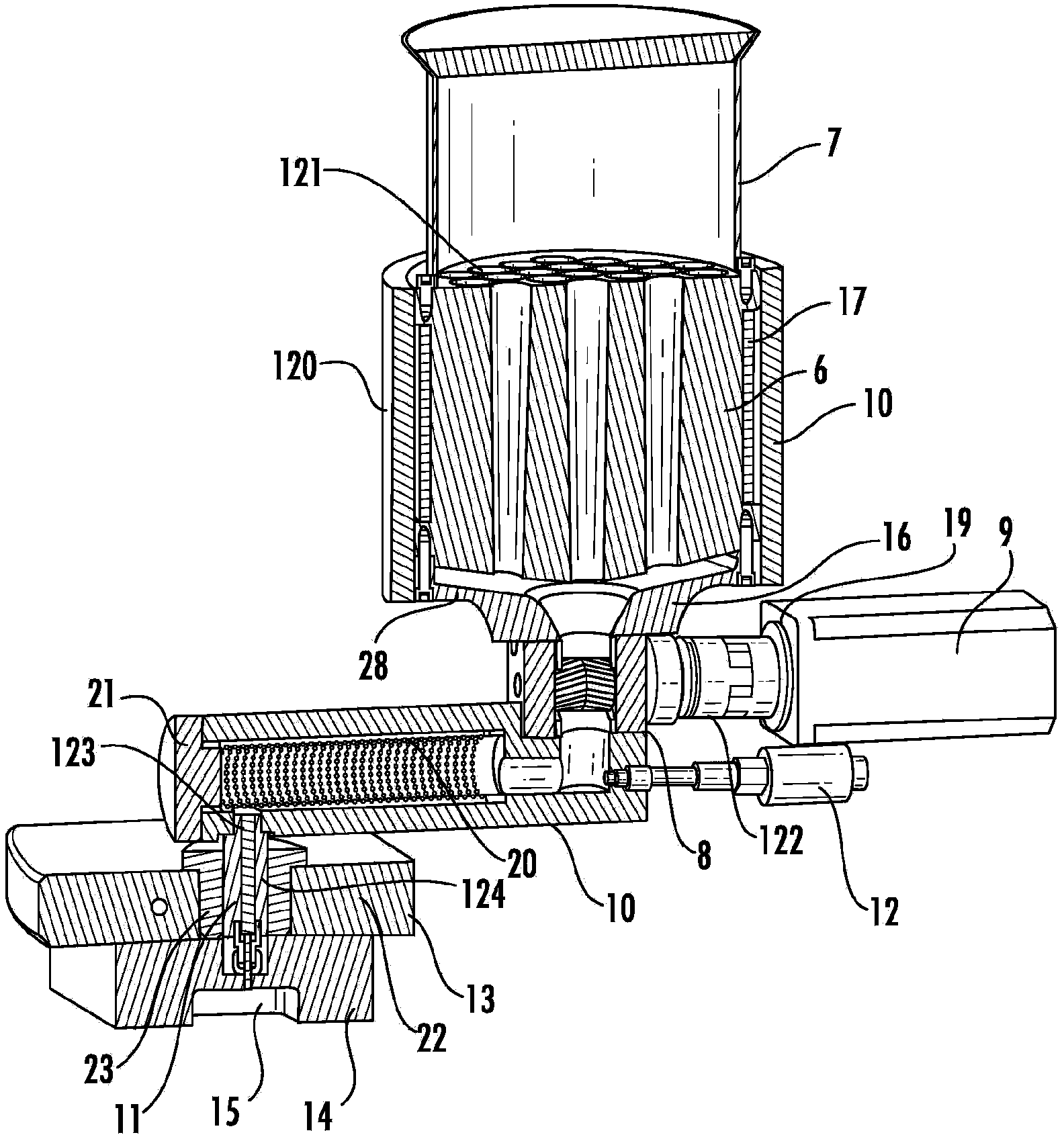

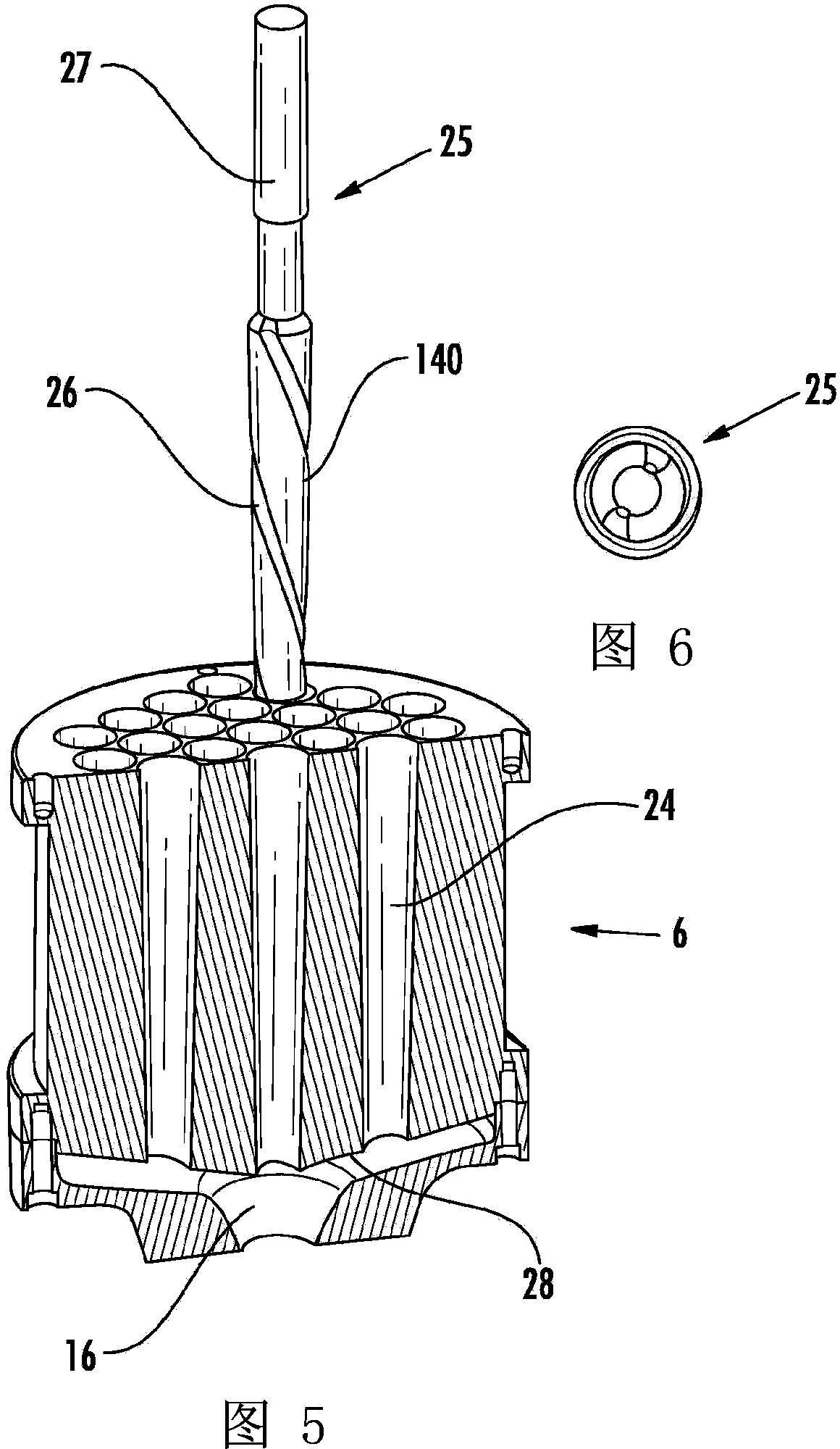

[0054] In the following detailed description of the preferred embodiments, a portion of this application is described with reference to the accompanying drawings. The drawings show by way of example specific embodiments for practicing the invention. It is to be understood that other embodiments may be utilized and structural changes may be made without departing from the scope of the present invention.

[0055] The present invention relates to apparatus and methods for forming. The methods and apparatus disclosed herein can be applied in many industries and applications, such as automotive manufacturing, wiring harness industry, sensor manufacturing and white goods industry. Examples of articles that can be molded using the method and apparatus of the present invention include, but are not limited to: encapsulation and exterior protection of electronic devices; printed circuit board encapsulation; strain relief molding on connectors, cables and wires; molding of insulating ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com