Single-phase outer rotor switch reluctance generator with U-shaped stator teeth

A switched reluctance and generator technology, applied in the direction of electrical components, electromechanical devices, magnetic circuit static parts, etc., can solve the problems of large number of power switching devices, complicated stator connection, high system cost, etc., and achieve simple structure, winding The effect of easy wiring and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

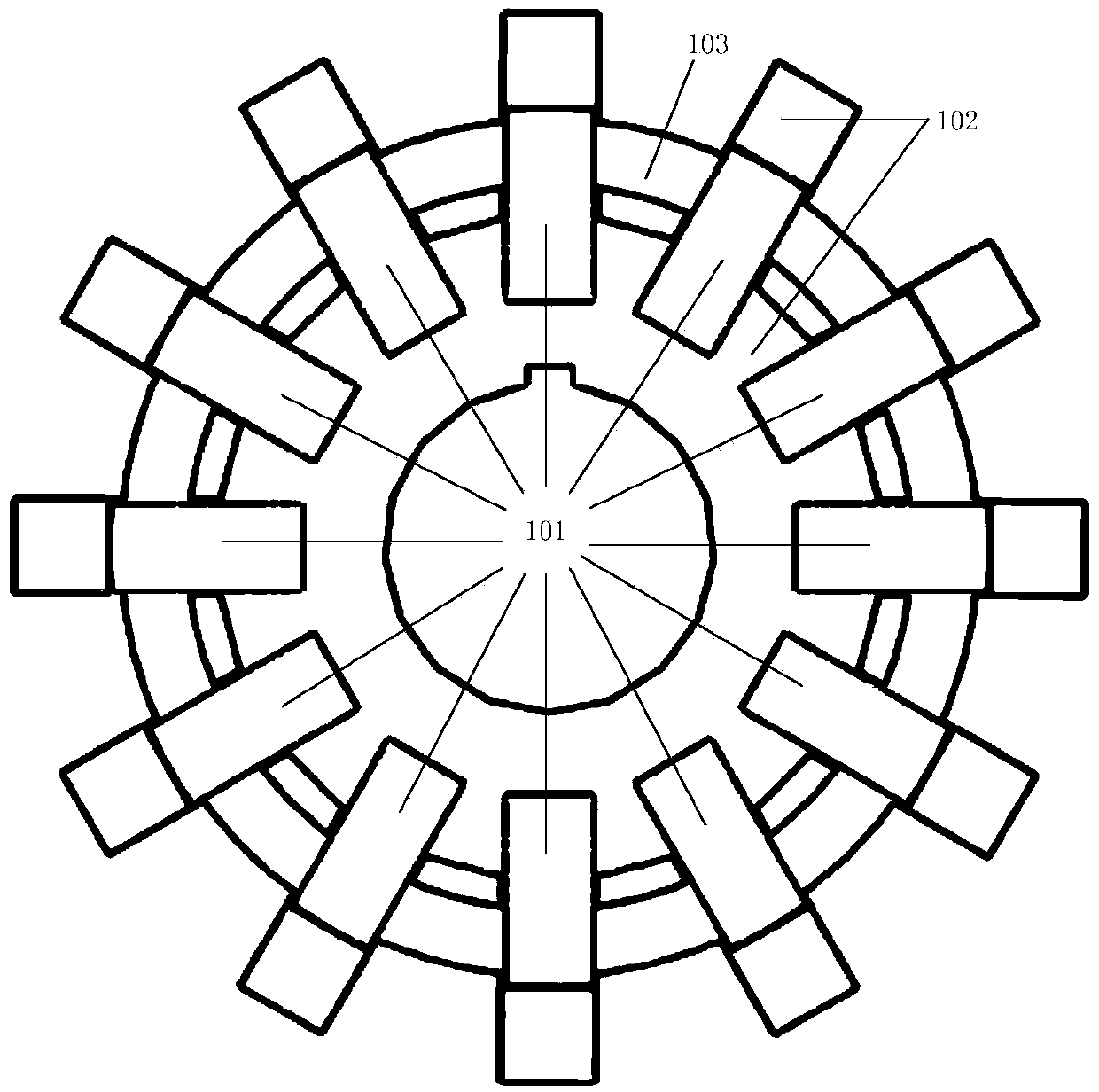

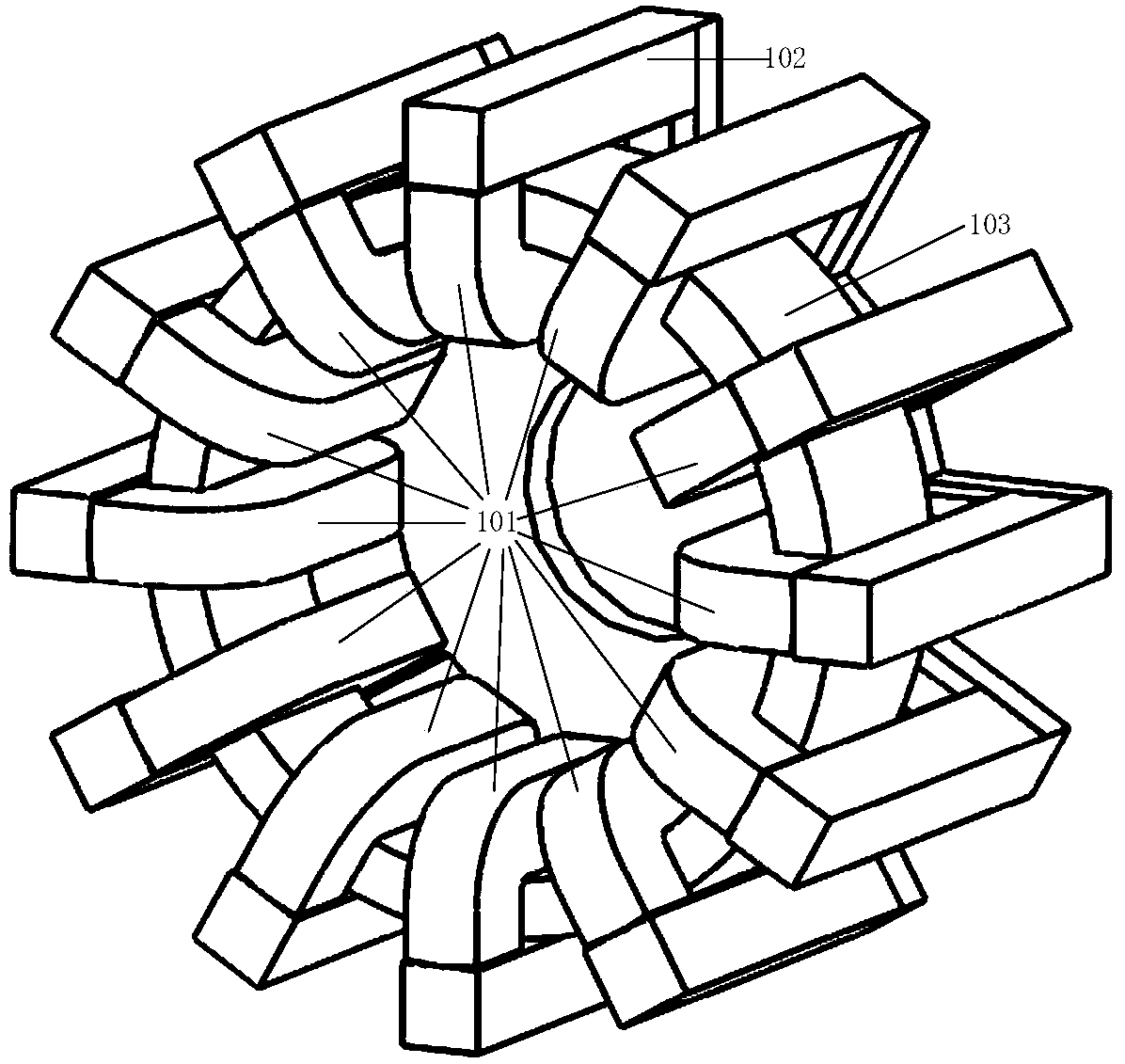

[0026] Such as figure 1 , figure 2 As shown, a single-phase U-shaped stator tooth external rotor switched reluctance generator includes a stator (101), a rotor (102) and a winding (103). The discs (104) with rectangular grooves made of non-magnetic material fix their positions with each other and are fixed on the casing (109) of the generator; The crankshaft (105) is connected; the winding (103) of the generator is a ring coil, which is wound in the U-shaped tooth groove of the stator (101); the rotor (102) is installed outside the circumference of the stator (101), and is formed by finger iron The rotor (102) has no brushes, no windings and permanent magnets, and is connected to the generator shaft (105) through a key (112). There are 12 teeth on the finger core; the generator is installed on the generator The permanent magnet (107) on the shaft (105) and the magnetic sensor (109) installed on the generator housing (108) detect the position of the rotor (102) in real time....

Embodiment 2

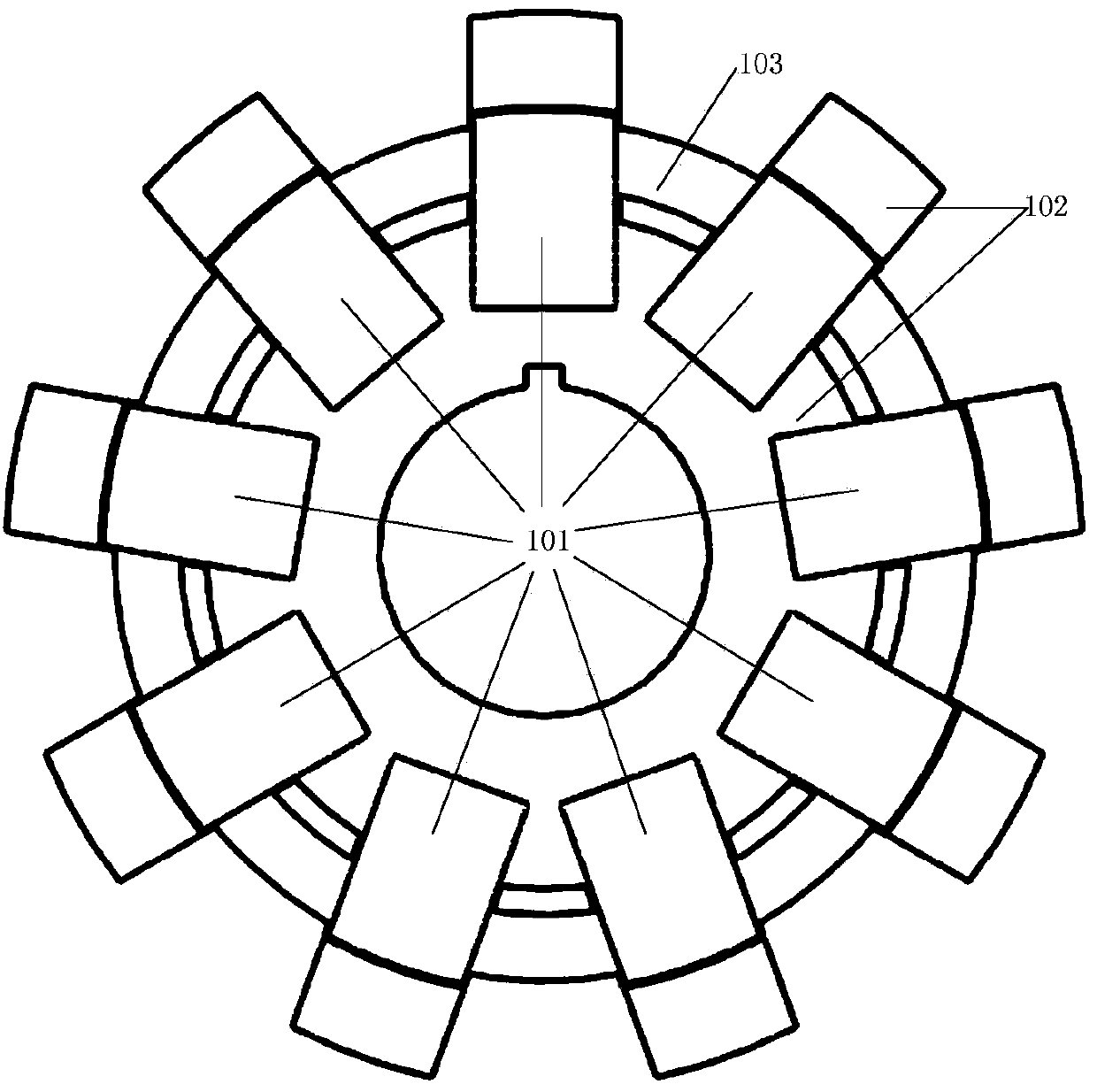

[0029] Such as image 3 , Figure 4As shown, a single-phase U-shaped stator tooth external rotor switched reluctance generator includes a stator (101), a rotor (102) and a winding (103). The discs (104) with rectangular grooves made of non-magnetic material fix their positions with each other and are fixed on the casing (109) of the generator; The crankshaft (105) is connected; the winding (103) of the generator is a ring coil, which is wound in the U-shaped tooth groove of the stator (101); the rotor (102) is installed outside the circumference of the stator (101), and is formed by finger iron The rotor (102) has no brushes, no windings and permanent magnets, and is connected with the generator shaft (105) through a key (112). There are 9 teeth on the finger core; the generator is installed on the generator The permanent magnet (107) on the shaft (105) and the magnetic sensor (109) installed on the generator casing (108) detect the position of the rotor (102) in real time. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com