Mistake-proof plug and electrical connector assembly using the same

A plug and anti-mistake technology, which is applied to the parts, connections, electrical components, etc. of the connection device, and can solve problems such as accidental plug drop-off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

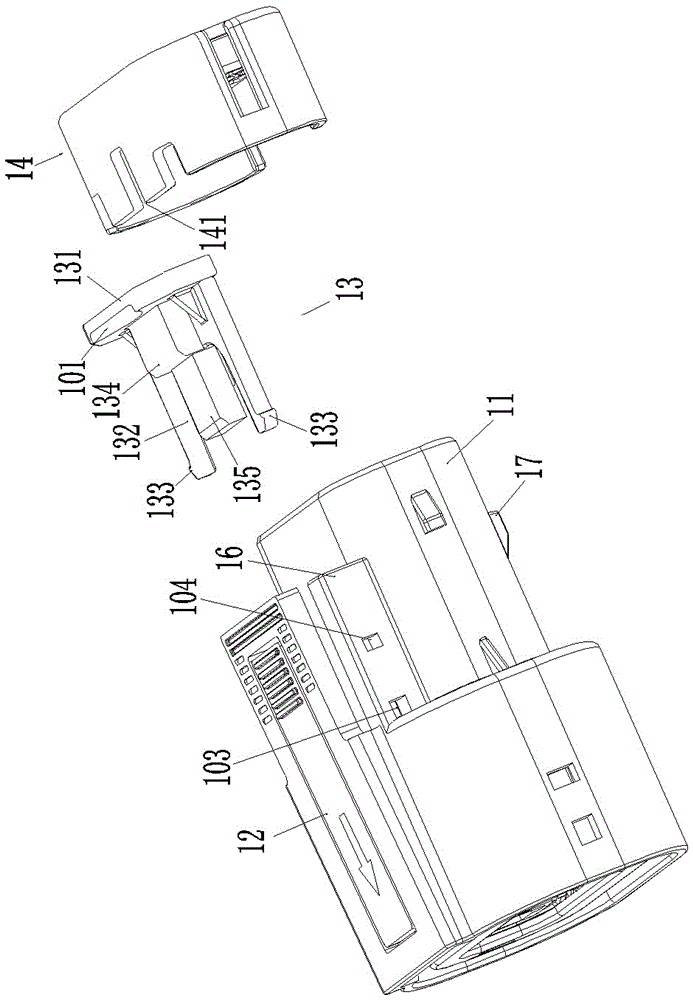

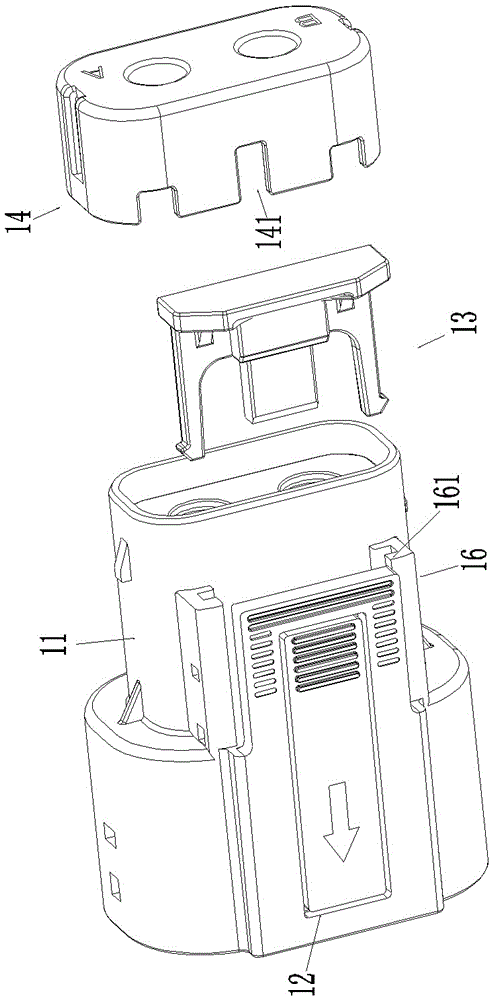

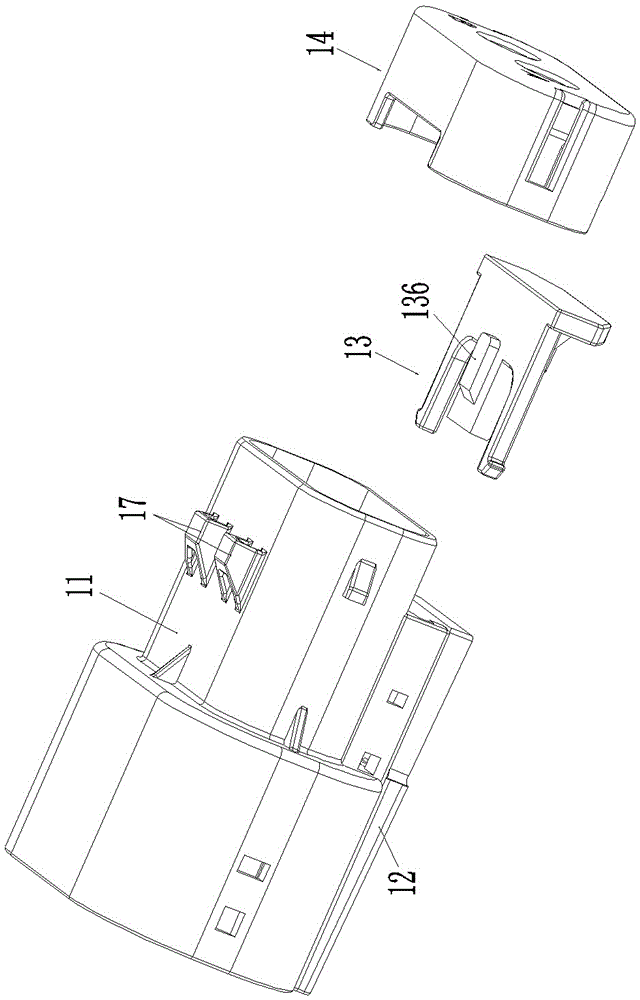

[0027] Embodiment 1 of the anti-mistake-off plug of the present invention, as Figure 1-8As shown, the plug takes the front end as the plug-in end, and includes a plug housing 11, and the plug housing 11 is provided with a claw 12. A seesaw structure is formed on the body 11; in addition, a safety slider 13 that can move back and forth is also provided on the plug housing 11, and the safety slider 13 is located at the rear end of the claw 12 and has a supporting structure. In this embodiment, the safety slider The block 13 includes a handle plate 131 positioned at the rear end, the front side of the handle plate 131 is respectively provided with snap fingers 132 on the left and right sides, each snap finger 132 has a bump on the front back, and the front side and the back side of the bump are formed by From the bottom to the top, it gradually tilts closer to the other side, wherein the slope of the front side of the projection is smaller than the slope of the rear side thereof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com