Automatic floating dock heaving control system

An automatic control system and floating dock technology, applied in the direction of electrical program control, program control in sequence/logic controller, marine transportation, etc., can solve the problems of incomplete function, stop, insufficient safety and reliability, etc., and achieve High degree of automation, automatic control, high safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

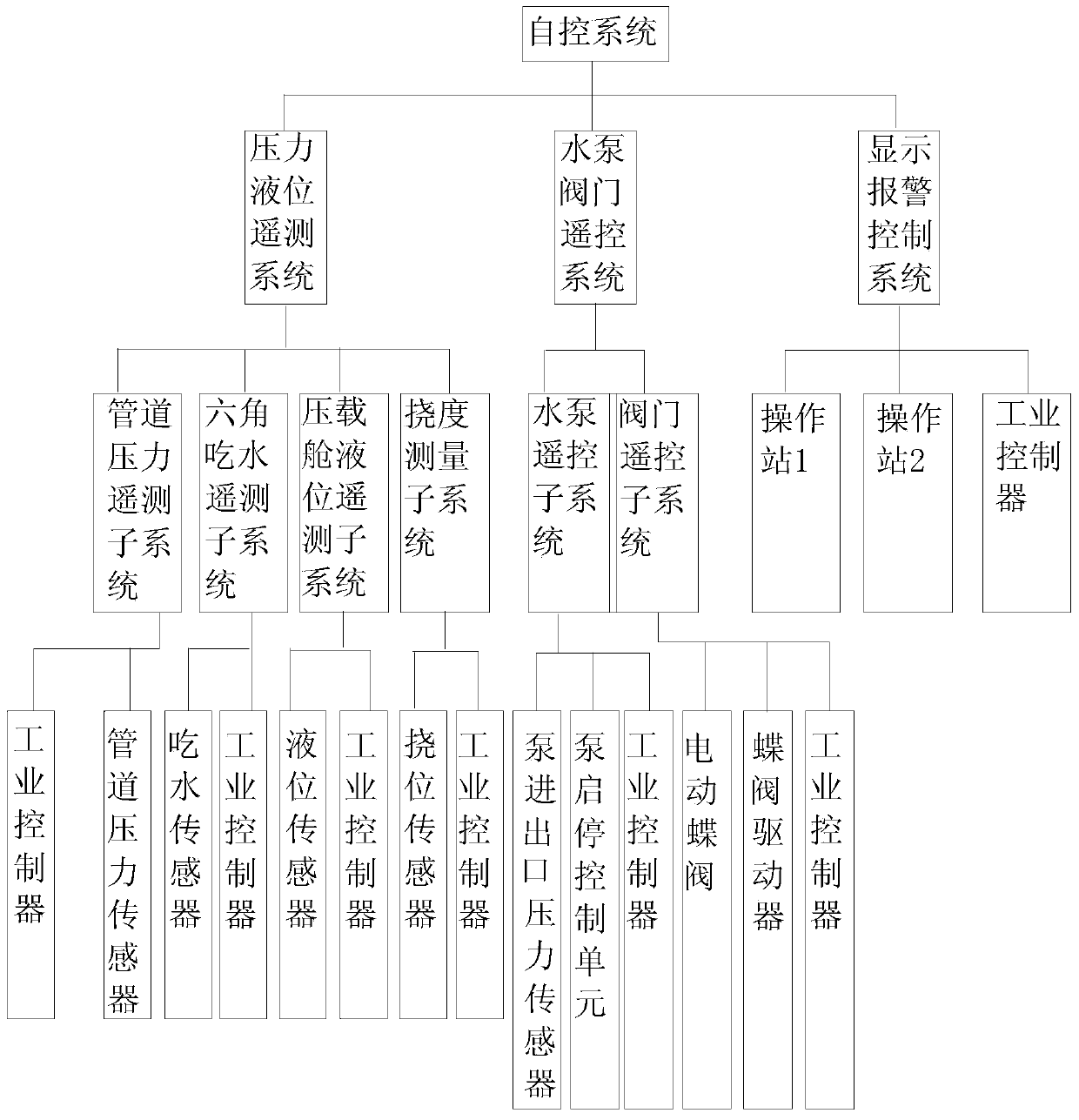

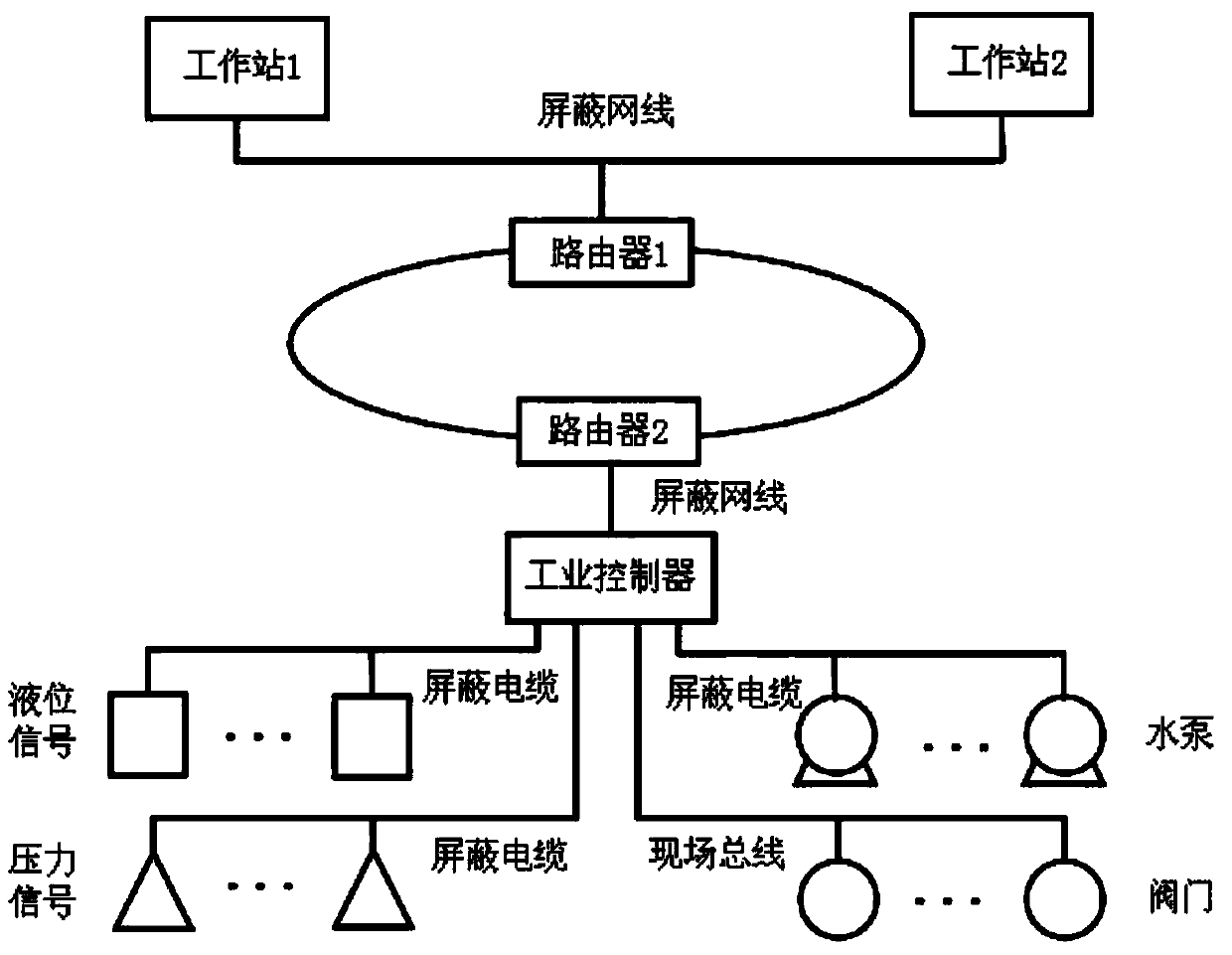

[0013] see attached figure 1 , the present invention provides a floating dock heave automatic control system, including a pressure liquid level remote measurement system, a water pump valve remote control system and a display alarm control system, the display alarm control system includes an operation terminal, a backup operation terminal and an industrial controller, The pressure liquid level remote measurement system and the water pump valve remote control system are connected to an industrial controller, and the industrial controller is connected to an operation terminal and a backup operation terminal through a router. The pressure liquid level remote measurement system includes a pipeline pressure remote measurement subsystem, a hexagon draft remote measurement subsystem, a ballast tank liquid level remote measurement subsystem and a deflection measurement subsystem, and each subsystem includes a control unit and a sensor unit. The pipeline pressure remote measurement sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com