Swing wear life test clamp of joint bearing

A joint bearing and test fixture technology, applied in the field of testing, can solve the problems of high failure probability, low installation and disassembly efficiency, and high test cost, and achieves the effects of reliable performance, improved installation and disassembly efficiency, and saving test time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

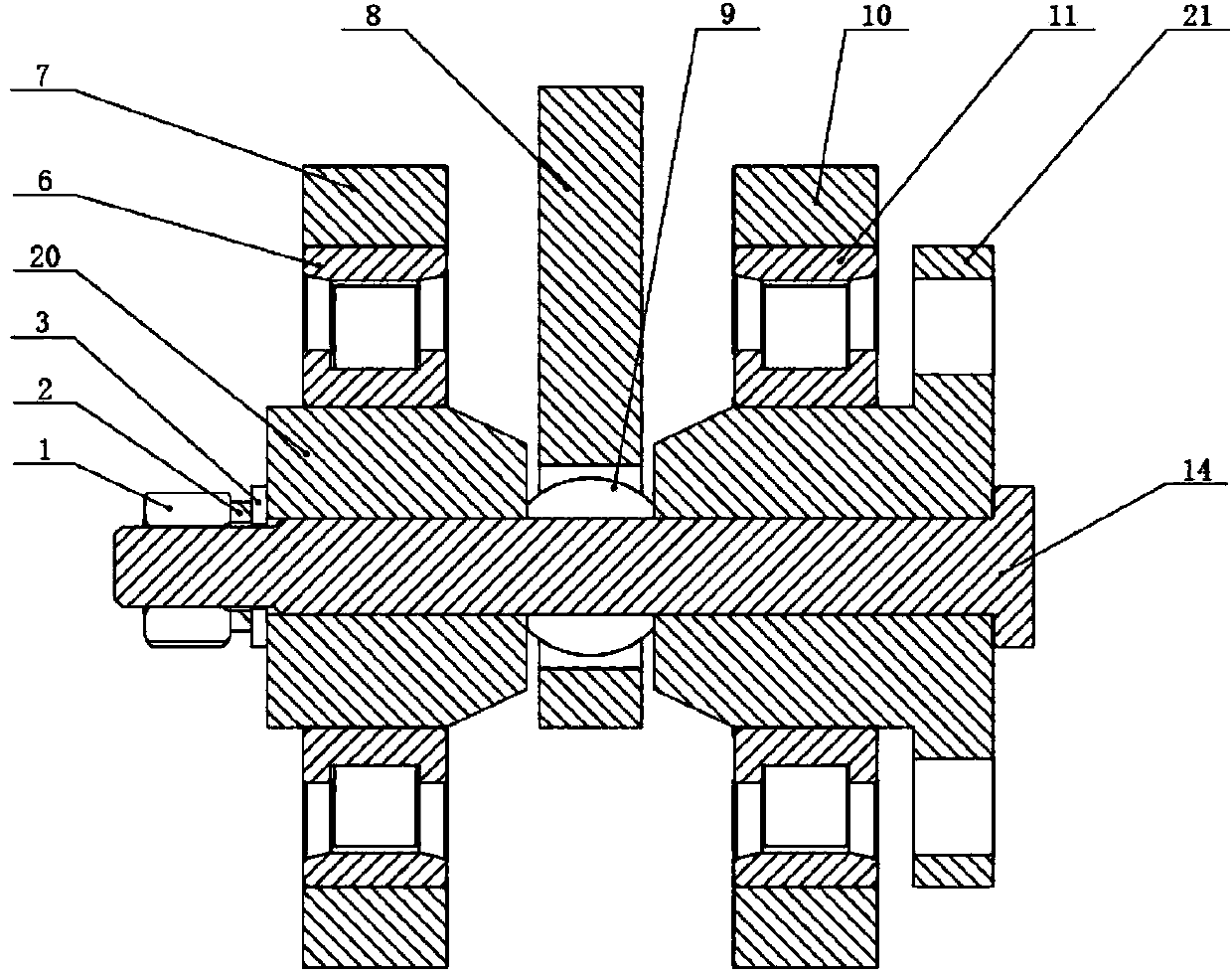

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings. Such as figure 2 As shown, the joint bearing swing wear life test fixture includes a mandrel 14 without a keyway, a left top sleeve 20, a right top sleeve 21, a left support bearing 6, a right support bearing 11, a left support 7 and a right support 10 and the loading plate 8, the mandrel 14 passes through the right top sleeve 21, the joint bearing 9 installed in the loading plate 8 and the left top sleeve 20 in turn, and the right top sleeve 21 is connected with the drive system at one end with a flange, and the other end is on the joint An inner ring end face of the bearing 9; the mandrel 14 has a shaft shoulder, and the shaft shoulder is pushed against the flanged end face of the right top sleeve 21, the shaft head of the mandrel 14 has an external thread, and the nut 1 and the spring on the mandrel 14 shaft head The washer 2 and the flat washer 3 make the left to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com